Ok here we go. I can't post Pic's in a PM so i have started a thread to show the pic's to Yellow Rose and anyone else that is interested.

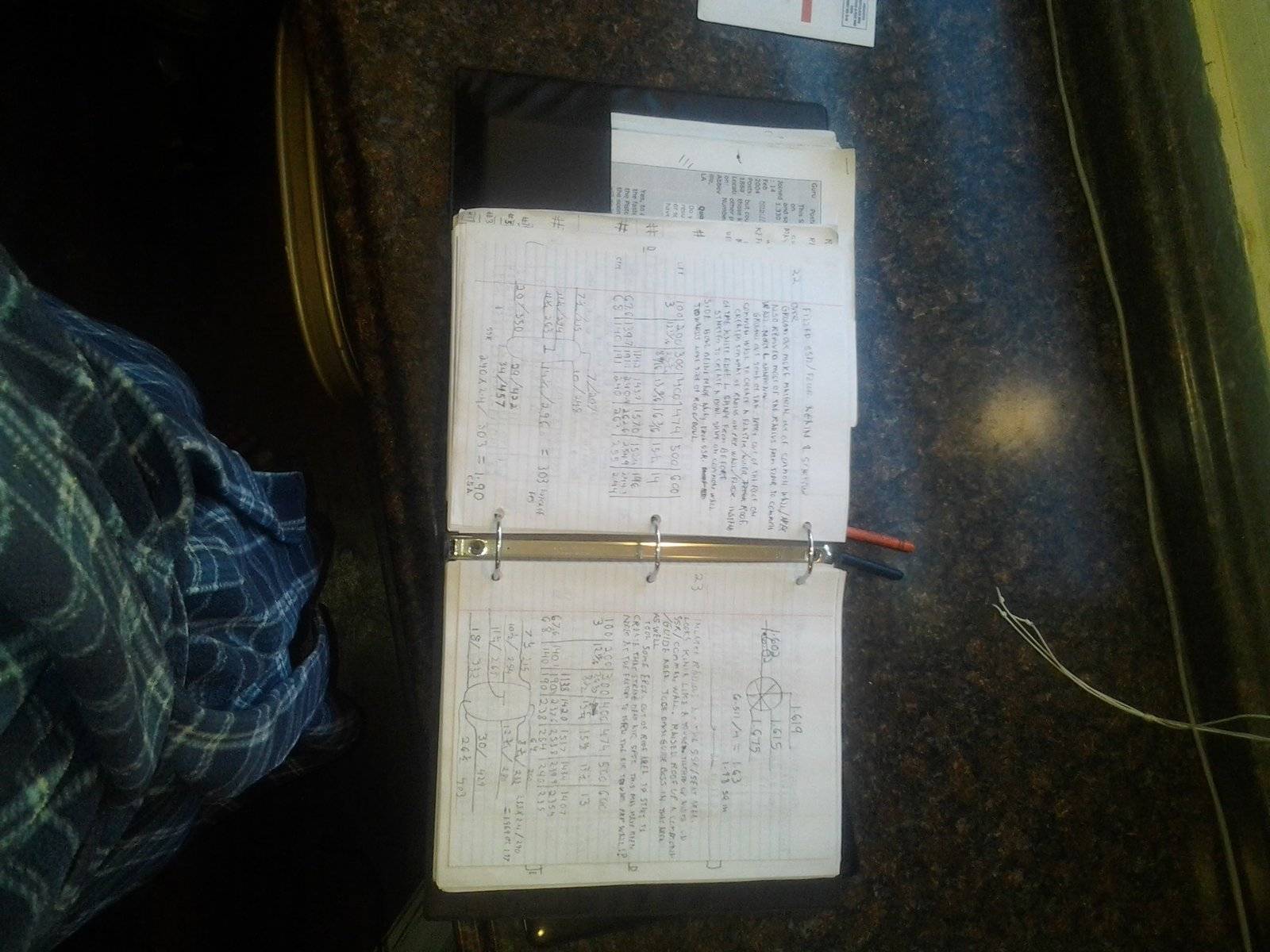

You told me i should take lot of notes this is all the notes for my 340/360 head porting.

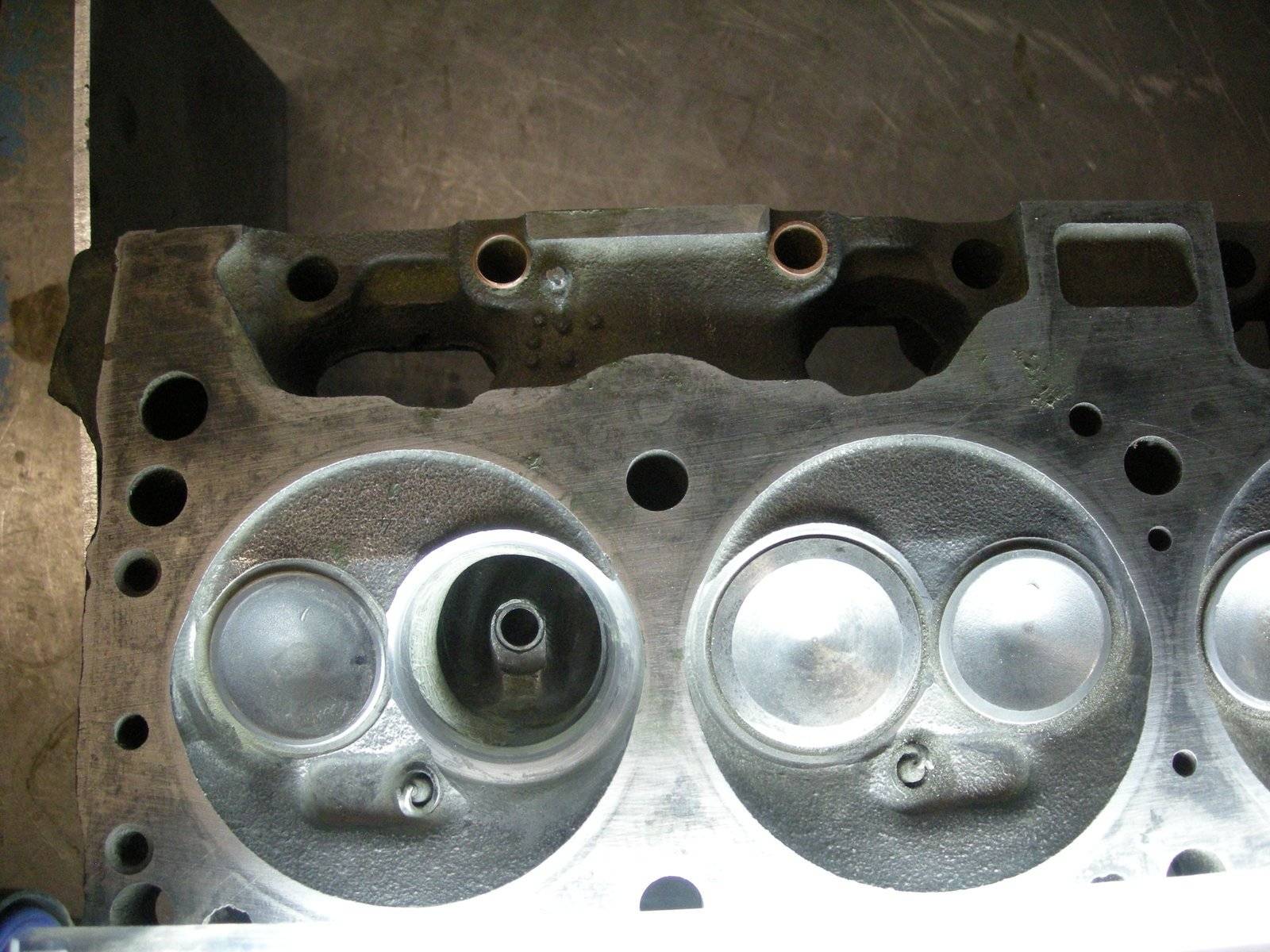

Here is the Clay Closed Closed Chamber

Notice that i have already tubed the pushrod tubes

failed attempts to raise the floor and make rounder/larger SSR

The next 2 pic's are the before.(there is a factory machined flat spot at the top of the seat. picture don't show it.)

And after when i finally got it to flow past. 500 lift. (said it was .550, i was mistaken)

That green looking stuff is called Z-spar. two part epoxy that when mixed turn that color.

Those scars are for sanding/shaping it with 36 grit sandpaper.

There you go ;)

You told me i should take lot of notes this is all the notes for my 340/360 head porting.

Here is the Clay Closed Closed Chamber

Notice that i have already tubed the pushrod tubes

failed attempts to raise the floor and make rounder/larger SSR

The next 2 pic's are the before.(there is a factory machined flat spot at the top of the seat. picture don't show it.)

And after when i finally got it to flow past. 500 lift. (said it was .550, i was mistaken)

That green looking stuff is called Z-spar. two part epoxy that when mixed turn that color.

Those scars are for sanding/shaping it with 36 grit sandpaper.

There you go ;)