Beams

Well-Known Member

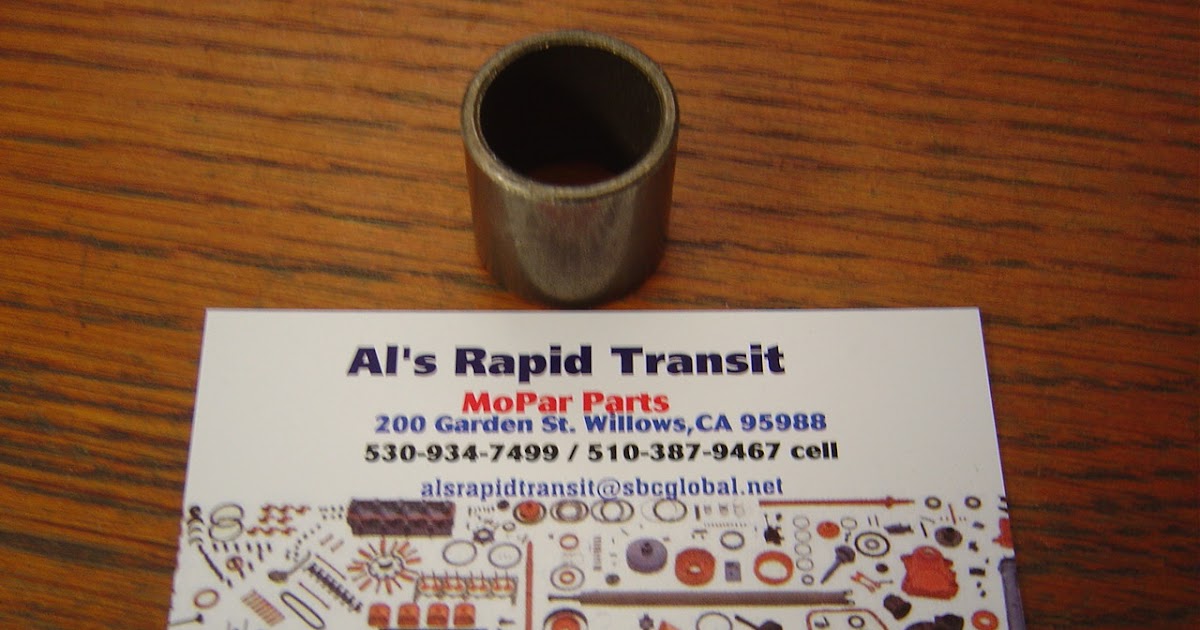

Working on a 1967 273, and need to put a pilot bushing in. The bushing I got from the clutch shop is not the same on both ends. They had placed the more beveled end facing out of the motor on the alignment tool. Is this how it should go? I’m assuming it makes a difference…

As always, appreciate the help.

As always, appreciate the help.