67fish383S

Well-Known Member

I imagine this topic has been covered many times before, and I suspect I already know where to start looking for my problem, but am looking for some shared wisdom. I did some searching of older threads and found several related posts, but nothing that fits my situation exactly. I apologize in advance for the wordiness to follow...

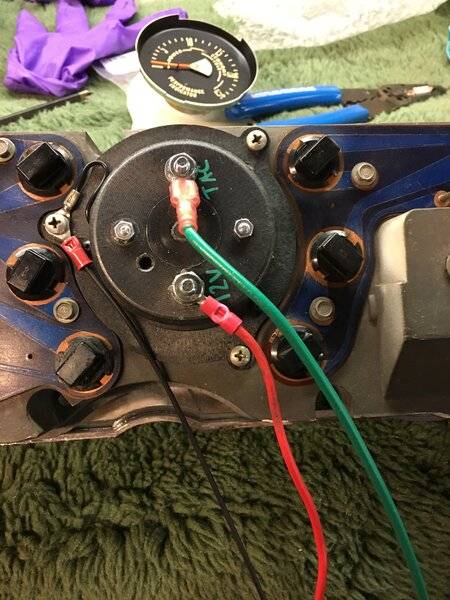

Here is the back story: I recently had the cluster out of the car to replace the vacuum gauge with a tachometer and upgrade the cluster lighting to LEDs. Prior to pulling the cluster, I bought a discreet voltage limiter because one was shown in the service manual mounted to the rear of the cluster, but found out later that in the rallye clusters, the limiter is built into the fuel gauge. I considered holding off on re-installing until I could do a solid state upgrade, but didn't have parts or a lot of info on it, so I stupidly plowed ahead and re-installed the cluster after bench testing all the LEDs.

Everything was great for a little while. All the existing gauges worked fine, the new tach was spot-on, and all the lighting was good. Cut to yesterday on my way to a car cruise...noticed the fuel, temp, and oil pressure needles all at zero. Dammit. Tach still working fine and all the lights were good. Immediately thought check the fuse (good of course). Then thoughts turned to the damn limiter or perhaps a loose connection or flaky solder joint in the cluster. Continued on the cruise having a full tank of fuel. A little while later, gauge function came back. Noticed the fuel needle 'wandering' a bit, but everything else seemed normal. A while later all dead again. By the time I got home, the tach was now effed up. Not completely dead, but the needle was below zero and not moving much.

The new tach has three connections: +12V, ground, and tach signal wires. I took the 12V off the blue wire at the ignition switch, because this had been previously tapped for the after market tach I was replacing, but thinking about it now, that was probably for the backlight. The old one got power from the fuse box. I ran the new tach ground to a screw on the dash frame.

So those are all of my symptoms. I still suspect the voltage limiter, but now wonder if the new tach wiring may be hosing the situation somehow. I really, really, don't want to pull the cluster again, but it seems like I won't be able to avoid it. If/when I do pull it again, I will go through all the connections and re-solder any pins/traces that look like they need it (what I should have done the first time).

Wondering if anyone has thoughts or suggestions. Also want to know more about how best to upgrade the limiter/fuel gauge situation. Please help. I am so tired of being folded like a pretzel under this dash lol.

Here is the back story: I recently had the cluster out of the car to replace the vacuum gauge with a tachometer and upgrade the cluster lighting to LEDs. Prior to pulling the cluster, I bought a discreet voltage limiter because one was shown in the service manual mounted to the rear of the cluster, but found out later that in the rallye clusters, the limiter is built into the fuel gauge. I considered holding off on re-installing until I could do a solid state upgrade, but didn't have parts or a lot of info on it, so I stupidly plowed ahead and re-installed the cluster after bench testing all the LEDs.

Everything was great for a little while. All the existing gauges worked fine, the new tach was spot-on, and all the lighting was good. Cut to yesterday on my way to a car cruise...noticed the fuel, temp, and oil pressure needles all at zero. Dammit. Tach still working fine and all the lights were good. Immediately thought check the fuse (good of course). Then thoughts turned to the damn limiter or perhaps a loose connection or flaky solder joint in the cluster. Continued on the cruise having a full tank of fuel. A little while later, gauge function came back. Noticed the fuel needle 'wandering' a bit, but everything else seemed normal. A while later all dead again. By the time I got home, the tach was now effed up. Not completely dead, but the needle was below zero and not moving much.

The new tach has three connections: +12V, ground, and tach signal wires. I took the 12V off the blue wire at the ignition switch, because this had been previously tapped for the after market tach I was replacing, but thinking about it now, that was probably for the backlight. The old one got power from the fuse box. I ran the new tach ground to a screw on the dash frame.

So those are all of my symptoms. I still suspect the voltage limiter, but now wonder if the new tach wiring may be hosing the situation somehow. I really, really, don't want to pull the cluster again, but it seems like I won't be able to avoid it. If/when I do pull it again, I will go through all the connections and re-solder any pins/traces that look like they need it (what I should have done the first time).

Wondering if anyone has thoughts or suggestions. Also want to know more about how best to upgrade the limiter/fuel gauge situation. Please help. I am so tired of being folded like a pretzel under this dash lol.

Last edited: