It was time to start fixing the tired wiring in my 46 yr old Barracuda. Time, and a half finished engine swap before I bought it had taken their toll on the electrical system. Since I plan to upgrade the charging system to support more electrical loads, it was obvious I needed to start at the battery:

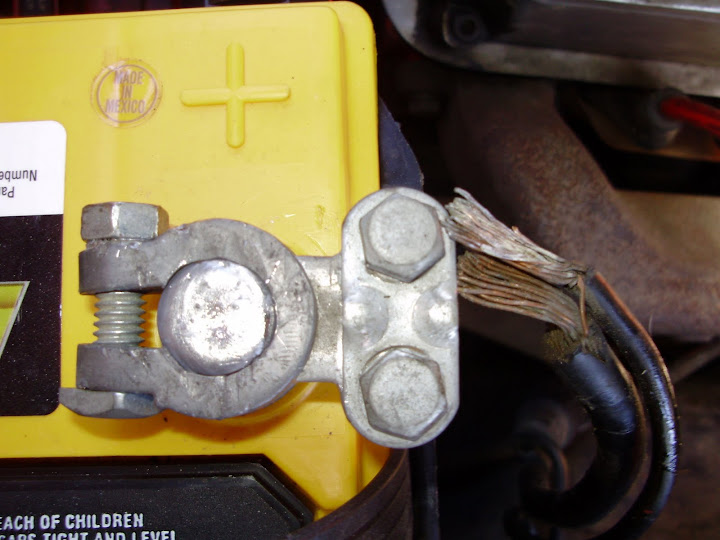

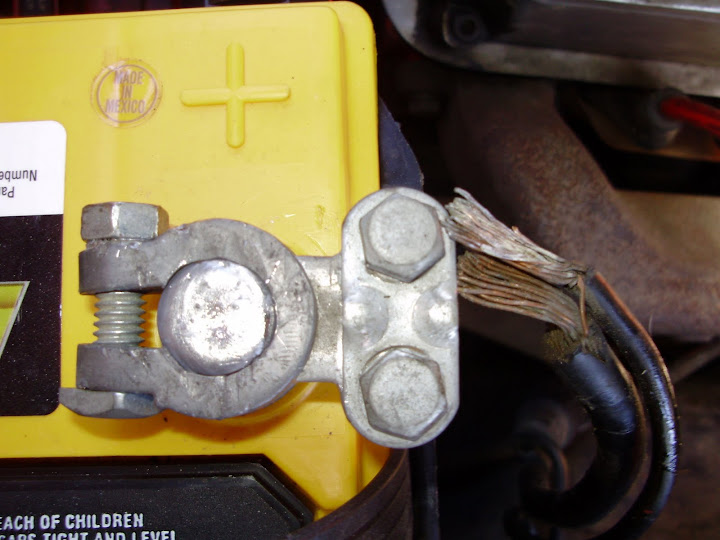

The original moulded cable from the starter was cut so short it barely reaches the junk terminal on the battery. Not only is this a poor job of installation, it is probably corroding in the clamp...

Yup. That sort of corrosion leads to hot conections, poor charging, dim lights...

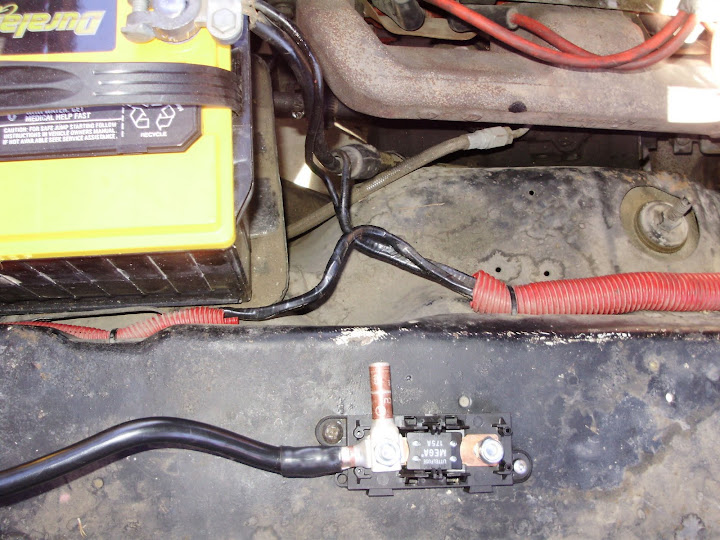

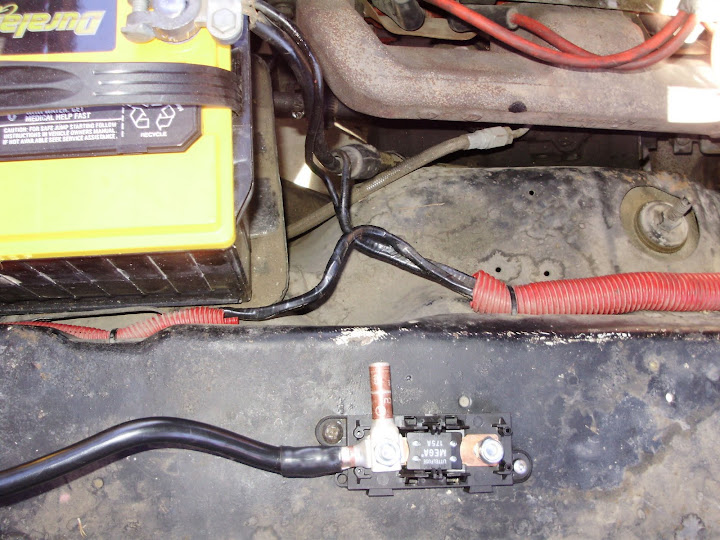

The bad news is that moulded cable is too short to re-terminate properly & still reach the battery. Since the OEM part will be hard to locate, and I want a larger gauge wire for the future 130 amp alternator - I will terminate it at a junction stud. Rather than use a single stud, I chose to use a MegaFuse for the rest of the system:

Crimping a battery cable requires a big crimper. There are much smaller hydraulic units around now, but the old lever type still does a great job.

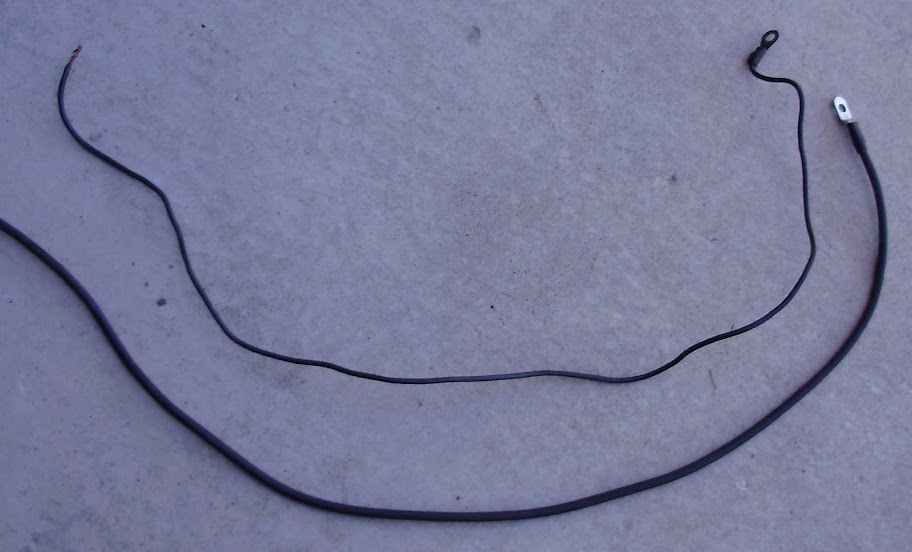

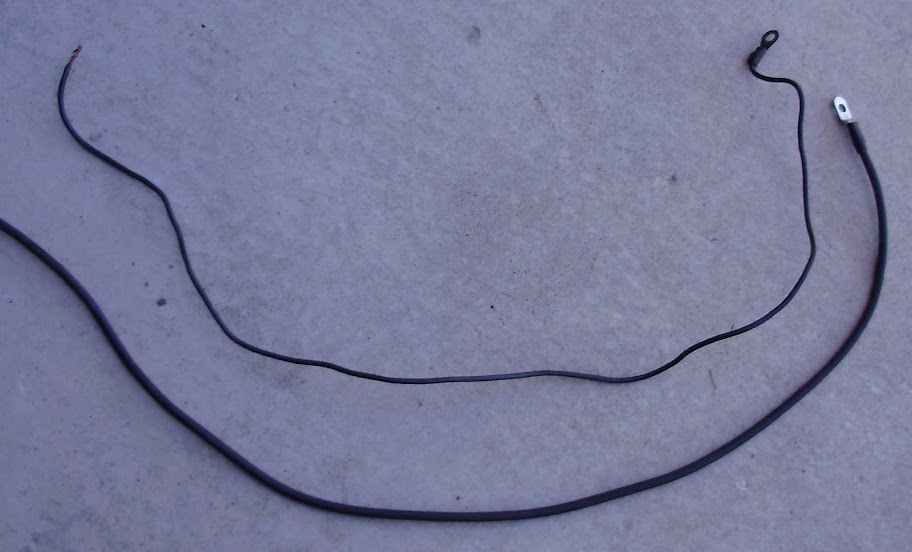

The next item leaving was the wire from the bulkhead connector to the battery. The OEM wire was way to small for a big alternator. I went with a piece of 4 gauge welding cable:

The welding cable was routed over to the start relay, where the OE wire was. At the start relay, it was obvious the Fusible Link had been replaced with what looks like a piece of building wire. Lucky for me I have a bolt down connection for the link at the bulkhead connector:

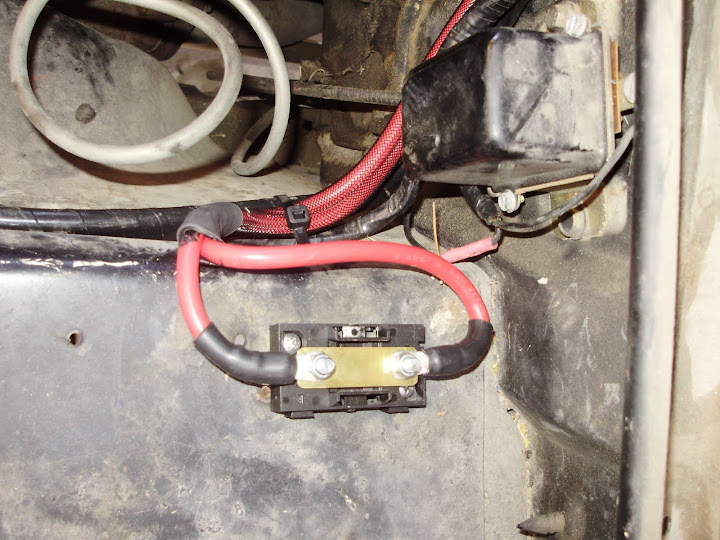

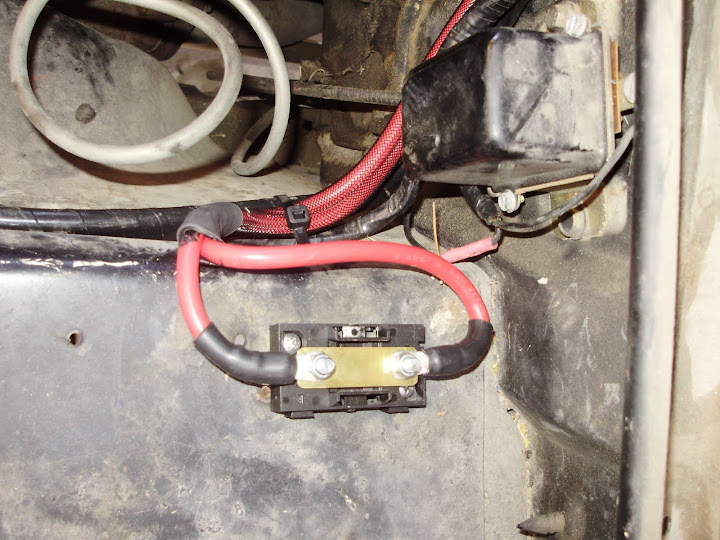

I replaced the fuse link with an 8 gauge wire, for a couple of reasons. I now have an actual fuse, and I have installed a current shunt to take some of the load off of the OEM ammeter. The in dash gauge still functions, but does not move as violently when loads change. It will be able to give me a reading with a 130 amp alternator in the system - without starting a fire. Here is the shunt:

And here is the finished installation of the MegaFuse & Shunt:

The shunt also provides a place to connect high current accessories like electric fans or relay boxes. The terminals on the shunt are just like the ammeter - if the load is on the correct side it will show a discharge if the load is greater than the alternator output. A relay box for the headlights is in the near future for sure, but I need to clean up some other wiring first...

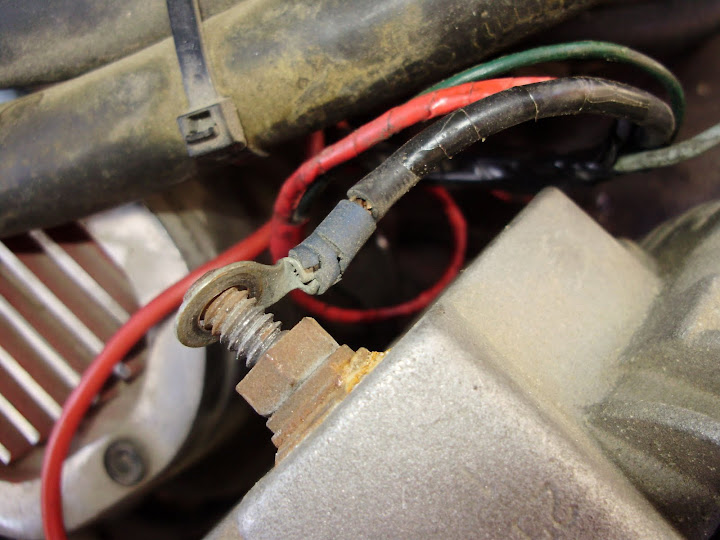

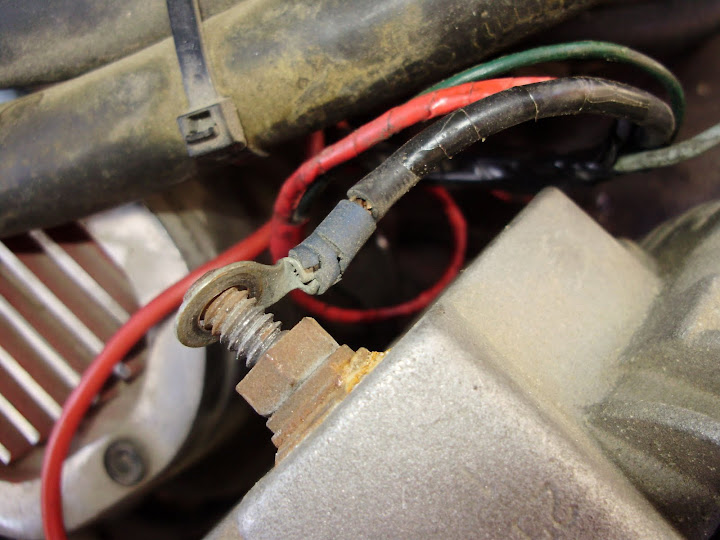

Yes, that really is the electric choke heater connected to the ballasted side of the coil circuit. No wonder it has a brand new ballast resistor on it. The terminal on the coil was so nice it needed it's own close up:

After I fixed all of that, I had a look at the terminal on the alternator output stud.

I was running out of time today, so I replaced the charge wire with a 4 gauge cable - but I still need to fix some other things in the harness on that side of the engine. I will take more pics when I get that cleaned up.

B.

The original moulded cable from the starter was cut so short it barely reaches the junk terminal on the battery. Not only is this a poor job of installation, it is probably corroding in the clamp...

Yup. That sort of corrosion leads to hot conections, poor charging, dim lights...

The bad news is that moulded cable is too short to re-terminate properly & still reach the battery. Since the OEM part will be hard to locate, and I want a larger gauge wire for the future 130 amp alternator - I will terminate it at a junction stud. Rather than use a single stud, I chose to use a MegaFuse for the rest of the system:

Crimping a battery cable requires a big crimper. There are much smaller hydraulic units around now, but the old lever type still does a great job.

The next item leaving was the wire from the bulkhead connector to the battery. The OEM wire was way to small for a big alternator. I went with a piece of 4 gauge welding cable:

The welding cable was routed over to the start relay, where the OE wire was. At the start relay, it was obvious the Fusible Link had been replaced with what looks like a piece of building wire. Lucky for me I have a bolt down connection for the link at the bulkhead connector:

I replaced the fuse link with an 8 gauge wire, for a couple of reasons. I now have an actual fuse, and I have installed a current shunt to take some of the load off of the OEM ammeter. The in dash gauge still functions, but does not move as violently when loads change. It will be able to give me a reading with a 130 amp alternator in the system - without starting a fire. Here is the shunt:

And here is the finished installation of the MegaFuse & Shunt:

The shunt also provides a place to connect high current accessories like electric fans or relay boxes. The terminals on the shunt are just like the ammeter - if the load is on the correct side it will show a discharge if the load is greater than the alternator output. A relay box for the headlights is in the near future for sure, but I need to clean up some other wiring first...

Yes, that really is the electric choke heater connected to the ballasted side of the coil circuit. No wonder it has a brand new ballast resistor on it. The terminal on the coil was so nice it needed it's own close up:

After I fixed all of that, I had a look at the terminal on the alternator output stud.

I was running out of time today, so I replaced the charge wire with a 4 gauge cable - but I still need to fix some other things in the harness on that side of the engine. I will take more pics when I get that cleaned up.

B.