Daves69

Well-Known Member

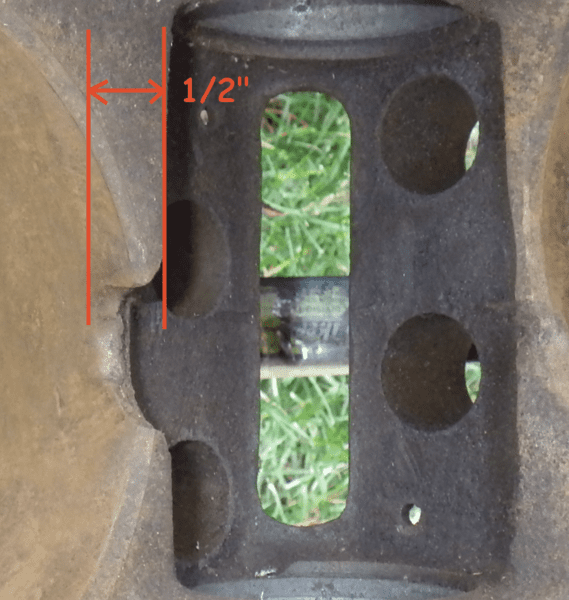

This is a '68 440 Hp block that has received modification to #4 cylinder by a wayward rod years ago. Approximately 1/2" chunk is bit out. Across the lifter alley #3 has just a small nick. Other than that, nothing else evident w/o throwing bucks at it.

For those in the know, how much is too much on #4 cylinder?

For those in the know, how much is too much on #4 cylinder?