pntastar69

Well-Known Member

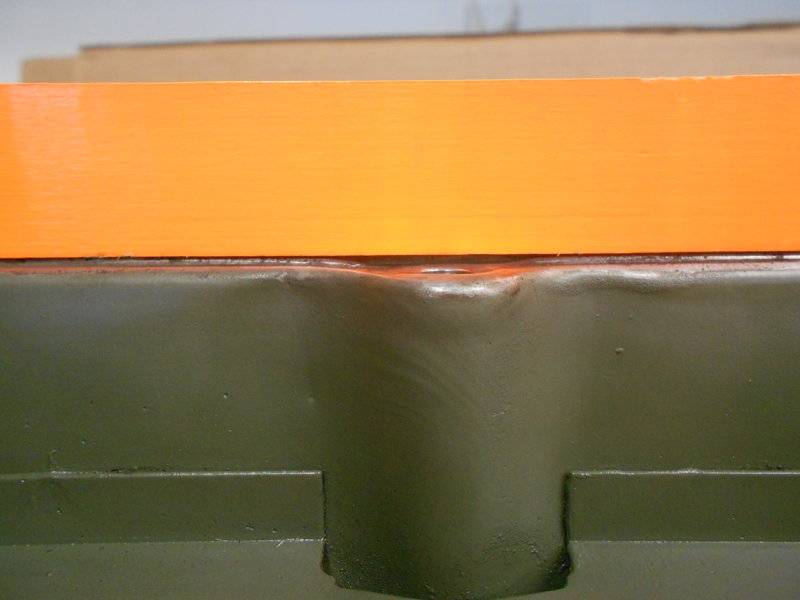

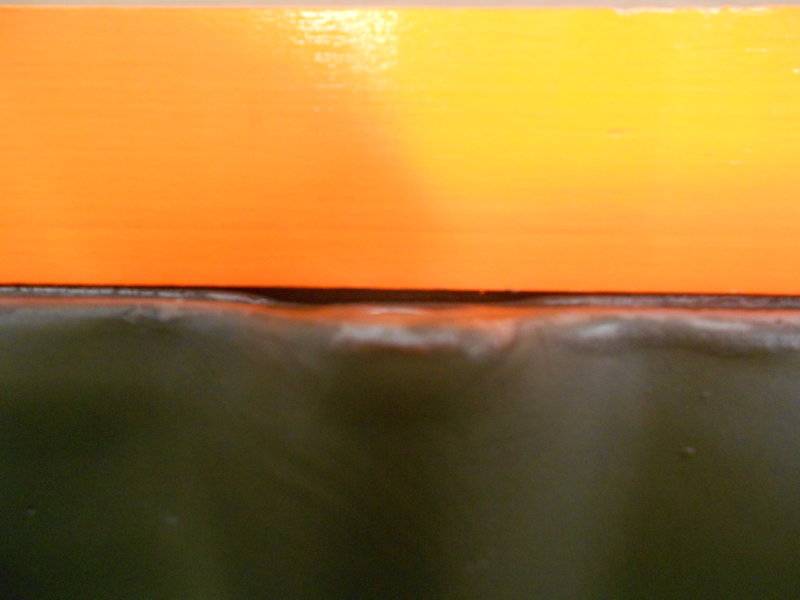

I will be going on my 4th set of valve cover gaskets on my 360 w/stock stamped VC’s, not the chrome ones. Dealing mostly w/seepage. I initially had the Moroso Blues on when I primed the engine and it leaked out of the right bank, middle hole on the exhaust side. Switched to Felpro corks, 3M snotted them to the VC and after several local jaunts, it was seeping on the exhaust side front and middile hole. Scrapped off all of the snot and went w/the Mopar black, hardened pcs and same results. And no, I did not over torque them, just hand tightened them. So I took them off again, scrapped all of the snot off and started checking for straightness. I managed to get the rails even and hammered the mounting bossed as they were sunk too low. The picture shows a ruler on the rails and the gap between the ruler (rail) and the mounting bosses.

Should the mounting bossed be flush w/the rails or sunken as seen in the picture?

Second question: If I get them straight, what gaskets should I order? The Mopar rubber w/steel cores are awfully expensive but I guess you pay for what you get.

Should the mounting bossed be flush w/the rails or sunken as seen in the picture?

Second question: If I get them straight, what gaskets should I order? The Mopar rubber w/steel cores are awfully expensive but I guess you pay for what you get.