Cuda68Scott

Well-Known Member

Hello FABO friends. I have been a member here quite some time, and follow many of your builds and posts. I am very grateful for this forum and the willingness of its members to pass on their knowledge, wisdom, humor, and friendship. Well I have finally decided to begin on my 1968 Barracuda after it has been sitting for about 36 years. I have done very little to the car since I stopped driving it around 1980. So, yes you might say I have been a slacker, thus the title of this build! I think (hope) having a restoration page thread will help me stay more focused and accountable. But I must forewarn you that you will probably see a fair amount of incompetence, indecision, and zero progress on this build! I look forward to your help and discussions so please feel to chime in and shame me to action if necessary!

Car History

The car is a 1968 318 Coupe with a 904 auto, 7 1/4 rear, and factory air. My uncle had bought the car new in New Mexico. In the summer of 1973 he passed away and I inherited the car. I was in high school at the time and had saved up about $1500 with the intent to purchase a used Duster 340 later that summer. I ended up using some of that $1500 to upgrade the Barracuda with wheels and various bolt-ons. When I picked up the car in New Mexico at my Uncle's residence it was in nearly perfect shape with only 28,000 miles on it. I drove it until about 1980 and it has since been parked at my residence. It has 100200 miles. The body is straight and virtually rust free on this car. I was in a few minor accidents, but had all the damages repaired at reputable body shops. So hopefully the prep work for painting will not be overly complicated but I am sure I will find some bondo in a few places.

Build Goals

Well I am not sure if I should discuss goals here, since that goes against the slacker's creed! I do wish to get the car in good, safe running condition, where I can relive my youth a bit, upset a few neighbors who find unexplainable twin tire marks in front of their homes, and maybe go to some local car shows and hang with the local Arizona FABO contingent. I plan to go through it mechanically and cosmetically where needed and can be afforded, and I hope it will end up as a very nice drivers class of car with a bit of a threatening exhaust rumble.

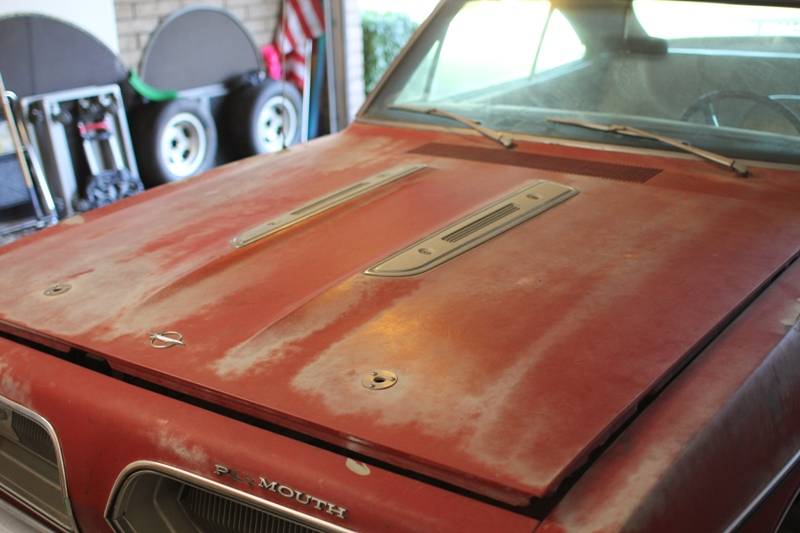

Over the years I have purchased Formula S badging and hood inserts, but the jury is still out if I will make it a Formula S clone. I have always been enamored with the 340 engine since I got whipped by so many 340 cars in the day. I would really like to have a ~500 horsepower 340 engine in this car, but I am not sure if that will be practical or within my financial means. John aka '67 cuda, has this monster MRL stroker 360 engine in his Cuda that I drool over, and I think since he lives in Nebraska and can't really drive the car in the winter that we should work out a timeshare agreement on his engine - I get it in the winter, he gets its back in the summer?

My son and I started some work on the car about 15 years ago but did not go far other than removing the rear end, gas tank, and front brakes. He did purchase an A body 8 3/4 with a 3.55s and an Auburn suregrip that will replace the 7.25. I had those door strips installed to prevent dings - they are riveted in - wish now I had never done that!

Don't judge! I thought the wings on the 340 Dusters were the coolest thing ever, so I went down and ordered an original one from the local Chrysler-Plymouth (Bill Luke) dealer in 1974 and installed it on my Barracuda. I don't think I will keep it on the car but I do get a lot of people that think it was stock. When people asked the purpose of the fin, I always told them it kept my back wheels on the ground when I topped 120 mph!

You guys remember the racing equipment stickers right! I think I will leave the bottom of the trunk lid including the stickers alone for sentimental reasons, plus the paint is still pretty nice on that side. There are two small drill holes in the lid right below the Accel decal that I cannot for the life of me remember why they are there. Fortunately the holes do not penetrate to the top.

Here is the mighty 318! Right after I got the car I installed Cyclone headers (not sure if they are still in business anymore), an Offenhauser 360 Dual Port intake, a Holley 600 vacuum secondary carb, an Accel dual point distributor (it broke and I put the original back in), and US Indy Mags with Goodyear Polyglas tires (H60s on the back, E70's on the front). The car ran and looked very good, and I was certainly not the slowest in town. I would get whipped by many, but I do remember beating an occasional 383 Roadrunner and some GM/Ford hipo cars in the day. I kept the car in extremely good tune, and I think that plus the relatively light weight of the Cuda is why I beat many cars that I felt normally should of had more than enough wheaties to take me.

I pulled my passenger bucket seat to see how the floors look. I did find a build sheet under that seat cushion. It fell to pieces when I tried to remove it due to being baked in the high Arizona heat. I plan to piece it back together.

Pulling the carpet back a bit under the seat reveals the floor pans have pristine shiny paint. Yep it's a southwest car, no rust on this baby! The yellow you see in lower left is just deteriorated seat cushion dust. I also found another build sheet under the carpet just past the drain plug you see in this pic, but it was not to this car. Boring day at the assembly line that day I guess.

Found a 3rd build sheet under the back seat cushion. I was able to get most of this one out without too much damage, but it is also extremely brittle. It's a 318 car, so no big deal on the build sheet, but I felt kind of like I was on an archaeological dig. Found a bunch of spare change on the carpet floor, all circa 1977, and also a gas receipt for $0.62 per gallon. Lots of fond memories...

I was a little surprised that I never used the back seat belts - they were under the back seat with the protective factor plastic wrap still around the clasps. I know I took people for rides all the time, guess I really did not worry about seat belts back then! How did we survive in those unsafe times LOL?

Trunk and entire car is rust free also thanks to our low humidity!

I think this may be the original spare or at least one of the original tires on the car - I don't recall ever using it. It's in really good shape, full tread and no age related cracking. It's a Goodyear size D70-14.

Dash is pretty heat worn with big cracks. About time for a new steering wheel cover! The Auto Meter tach always worked great.

My uncle liked his cigars and an occasional bit of the nip. Apparently he missed the lighter hole a few times putting it back in the dark! He was a great guy and I still think about him when I look at the car. I think I will leave these marks untouched in his memory.

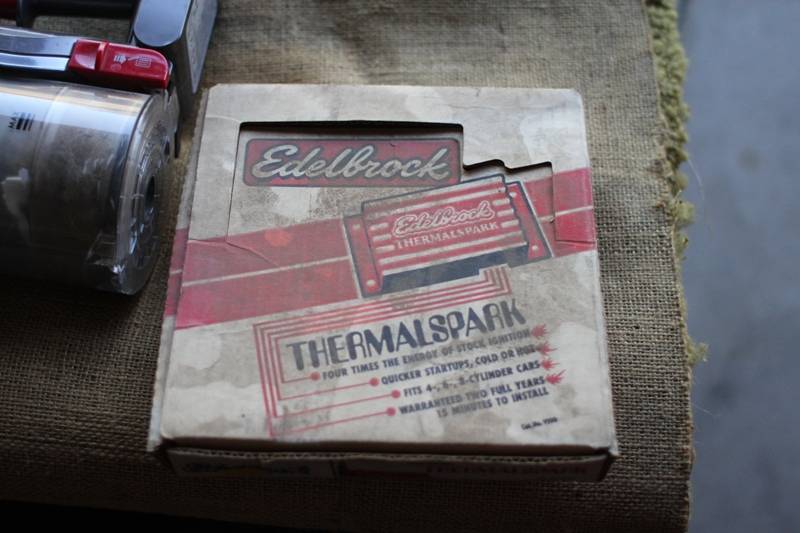

Found this box in the trunk, not sure why I kept it. The Edelbrock marketing boys probably had some ad in Hot Rod Magazine that got me hooked into buying this - pretty sure they suggested some big % horsepower increase. You can see it on the engine bay picture on the passenger fenderwall. I am not sure it did much for hotter spark or horsepower but my high school friends thought it was bitchin. I probably claimed my horsepower went up 20 for bragging rights.

Don't know how many of you had Checker Auto Parts store in your area, but they once had a lifetime warranty on one of their batteries. They lost money with me as I got a lot of free batteries over the years!

Well that's it for now and if you have read this entire post to here, please go get a beer! I plan on tackling the front brakes and suspension first, so I will start posting progress pictures any time now, so says the slacker!

Car History

The car is a 1968 318 Coupe with a 904 auto, 7 1/4 rear, and factory air. My uncle had bought the car new in New Mexico. In the summer of 1973 he passed away and I inherited the car. I was in high school at the time and had saved up about $1500 with the intent to purchase a used Duster 340 later that summer. I ended up using some of that $1500 to upgrade the Barracuda with wheels and various bolt-ons. When I picked up the car in New Mexico at my Uncle's residence it was in nearly perfect shape with only 28,000 miles on it. I drove it until about 1980 and it has since been parked at my residence. It has 100200 miles. The body is straight and virtually rust free on this car. I was in a few minor accidents, but had all the damages repaired at reputable body shops. So hopefully the prep work for painting will not be overly complicated but I am sure I will find some bondo in a few places.

Build Goals

Well I am not sure if I should discuss goals here, since that goes against the slacker's creed! I do wish to get the car in good, safe running condition, where I can relive my youth a bit, upset a few neighbors who find unexplainable twin tire marks in front of their homes, and maybe go to some local car shows and hang with the local Arizona FABO contingent. I plan to go through it mechanically and cosmetically where needed and can be afforded, and I hope it will end up as a very nice drivers class of car with a bit of a threatening exhaust rumble.

Over the years I have purchased Formula S badging and hood inserts, but the jury is still out if I will make it a Formula S clone. I have always been enamored with the 340 engine since I got whipped by so many 340 cars in the day. I would really like to have a ~500 horsepower 340 engine in this car, but I am not sure if that will be practical or within my financial means. John aka '67 cuda, has this monster MRL stroker 360 engine in his Cuda that I drool over, and I think since he lives in Nebraska and can't really drive the car in the winter that we should work out a timeshare agreement on his engine - I get it in the winter, he gets its back in the summer?

My son and I started some work on the car about 15 years ago but did not go far other than removing the rear end, gas tank, and front brakes. He did purchase an A body 8 3/4 with a 3.55s and an Auburn suregrip that will replace the 7.25. I had those door strips installed to prevent dings - they are riveted in - wish now I had never done that!

Don't judge! I thought the wings on the 340 Dusters were the coolest thing ever, so I went down and ordered an original one from the local Chrysler-Plymouth (Bill Luke) dealer in 1974 and installed it on my Barracuda. I don't think I will keep it on the car but I do get a lot of people that think it was stock. When people asked the purpose of the fin, I always told them it kept my back wheels on the ground when I topped 120 mph!

You guys remember the racing equipment stickers right! I think I will leave the bottom of the trunk lid including the stickers alone for sentimental reasons, plus the paint is still pretty nice on that side. There are two small drill holes in the lid right below the Accel decal that I cannot for the life of me remember why they are there. Fortunately the holes do not penetrate to the top.

Here is the mighty 318! Right after I got the car I installed Cyclone headers (not sure if they are still in business anymore), an Offenhauser 360 Dual Port intake, a Holley 600 vacuum secondary carb, an Accel dual point distributor (it broke and I put the original back in), and US Indy Mags with Goodyear Polyglas tires (H60s on the back, E70's on the front). The car ran and looked very good, and I was certainly not the slowest in town. I would get whipped by many, but I do remember beating an occasional 383 Roadrunner and some GM/Ford hipo cars in the day. I kept the car in extremely good tune, and I think that plus the relatively light weight of the Cuda is why I beat many cars that I felt normally should of had more than enough wheaties to take me.

I pulled my passenger bucket seat to see how the floors look. I did find a build sheet under that seat cushion. It fell to pieces when I tried to remove it due to being baked in the high Arizona heat. I plan to piece it back together.

Pulling the carpet back a bit under the seat reveals the floor pans have pristine shiny paint. Yep it's a southwest car, no rust on this baby! The yellow you see in lower left is just deteriorated seat cushion dust. I also found another build sheet under the carpet just past the drain plug you see in this pic, but it was not to this car. Boring day at the assembly line that day I guess.

Found a 3rd build sheet under the back seat cushion. I was able to get most of this one out without too much damage, but it is also extremely brittle. It's a 318 car, so no big deal on the build sheet, but I felt kind of like I was on an archaeological dig. Found a bunch of spare change on the carpet floor, all circa 1977, and also a gas receipt for $0.62 per gallon. Lots of fond memories...

I was a little surprised that I never used the back seat belts - they were under the back seat with the protective factor plastic wrap still around the clasps. I know I took people for rides all the time, guess I really did not worry about seat belts back then! How did we survive in those unsafe times LOL?

Trunk and entire car is rust free also thanks to our low humidity!

I think this may be the original spare or at least one of the original tires on the car - I don't recall ever using it. It's in really good shape, full tread and no age related cracking. It's a Goodyear size D70-14.

Dash is pretty heat worn with big cracks. About time for a new steering wheel cover! The Auto Meter tach always worked great.

My uncle liked his cigars and an occasional bit of the nip. Apparently he missed the lighter hole a few times putting it back in the dark! He was a great guy and I still think about him when I look at the car. I think I will leave these marks untouched in his memory.

Found this box in the trunk, not sure why I kept it. The Edelbrock marketing boys probably had some ad in Hot Rod Magazine that got me hooked into buying this - pretty sure they suggested some big % horsepower increase. You can see it on the engine bay picture on the passenger fenderwall. I am not sure it did much for hotter spark or horsepower but my high school friends thought it was bitchin. I probably claimed my horsepower went up 20 for bragging rights.

Don't know how many of you had Checker Auto Parts store in your area, but they once had a lifetime warranty on one of their batteries. They lost money with me as I got a lot of free batteries over the years!

Well that's it for now and if you have read this entire post to here, please go get a beer! I plan on tackling the front brakes and suspension first, so I will start posting progress pictures any time now, so says the slacker!

Last edited: