Serj22

Well-Known Member

After a lot -and I mean a lot of reading, I decided I had the basic idea down, to go ahead and put a turbo on my '68 Dart. Turbos are no longer scary sounding to me to put on, so I'm going to go for it. This is of course a budget build, and I am merely shooting for 200hp @ somewhere under 8-9lbs. This is still a daily driver so reliability will be prevalent. I am definitly not an expert and any help people can give along the way is incredibly appreciated. If I breech 200 hp, then awesome - but I am keeping the standards low, to be more excited in the end.

So far I have paid:

Motorcraft 2150: $40

Ebay T3/T4 Turbo new: $120

Blow Off Valve: $10

Wastegate: $10

Manual Boost Controller: $10

Downpipe for turbine: $free

Extra Stock exhaust manifold: $20

The plan is to run my 2bbl Supersix manifold adapted to fit a Motorcraft 2150 - or maybe something else if I determine later, but this is what I have for now. The exhaust I want to run a J-pipe off of to locate the turbo near where the A/C would have been on my motor, and then use the two bolt holes in the block to make a mount to support the turbo to. Then I will plumb the "cold" side directly to a ITB ram hat on top of the carb. I have not decided on an intercooler yet, but it will be a blow-through setup.

I then want to go simple on the oil and go from the filter fitting over to the turbo. Then drain out to a punched hole in the pan. I want to reference the stock fuel pump and hopefully it will meet my minimal boost demands. I will try and get the distributor limited to 18deg total advance since that's what everyone else seems to recommend, to limit the possiblity of detonation. I also will run a wideband sensor so I'm not in the dark with the carb and weather or not it is functioning.

(I got everything but the carb in a package deal off sl6.org. good deal)

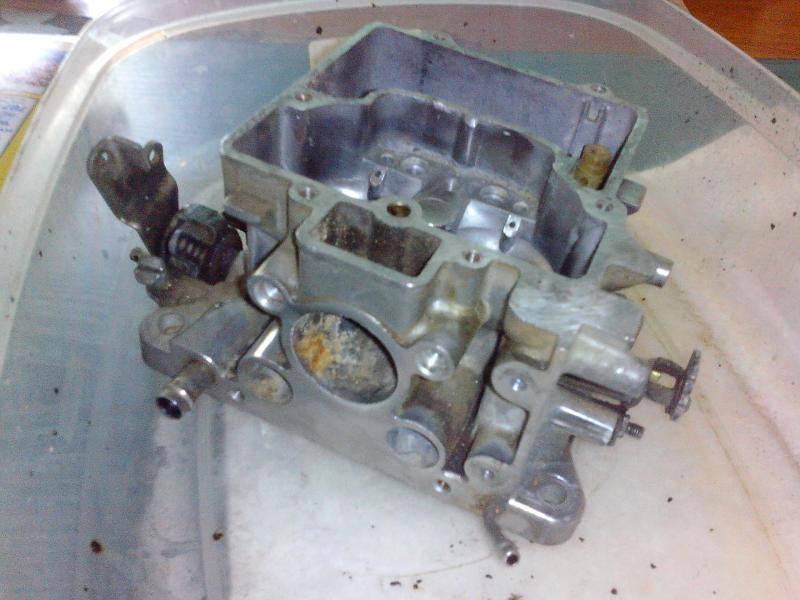

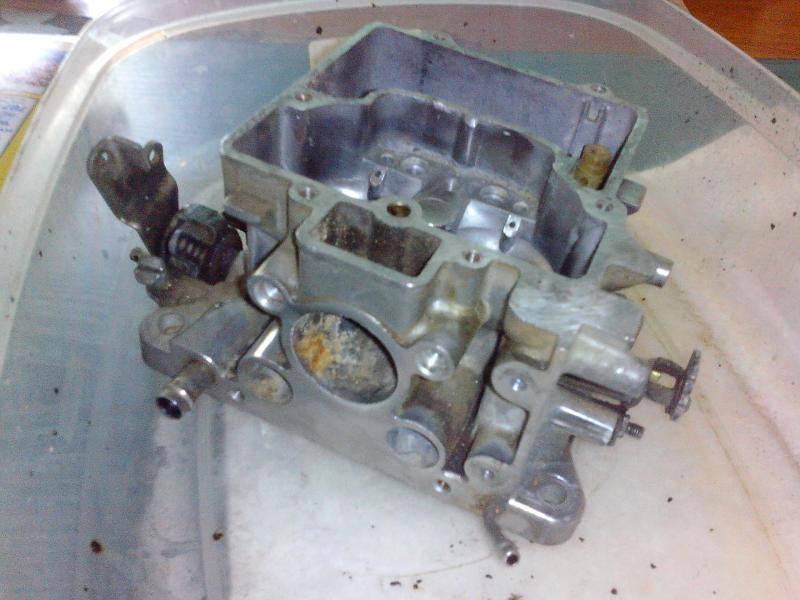

So far, I just have a carburetor to start with, that cost me a whopping $30, and rebuilt it for $15, added nitrophyl float, and a seat that allows more flow. I got rid of all the choke peripherals except for the actual choke coil which is the only axis available to make the cam for idle function unfortunately, otherwise I would have removed it all together. Then I filled the choke lever hole, and cut most of the choke riser off.

I got rid of a serious air leak on the bottom that I could not figure out how to adapt, so I J-b'd it and then drilled a couple holes underneath the filler to make it hopefully operate just the same as it did before.

The leak is what you see at the bottom furthest away from the power valve cover:

http://i43.photobucket.com/albums/e356/serj22/IMG_20140712_223451_zps3380b8fa.jpg

No doubt i possibly had to go buy the actual riser, but I figured this would work around it. I saw a thread where someone shoved a rag into the gap to cut the leak. I think this maybe a little more sophisticated. I leveled the area with JB weld in the carb, then knifed it flush and sanded it straight to be at the same level as the carb base. Hopefully it functions. Then I drilled two holes from each side underneath since this was originally a air passage. I was debating if I could just drill between the two barrels and just seal it up, but I figured that may mess something up somehow.

http://i43.photobucket.com/albums/e356/serj22/IMG_20140724_151030_zps98d64868.jpg

I wrote on the cover of the power valve what I drilled the passage to so I could keep track of what I do with it. I'm still trying to figure out how to convert the PV, since it looks similar to a Holley one, but the retainer on the spring is different. -I'm not sure if it would come apart the same to make a BRPV.

I'[m still trying to figure out what this side port is for in the picture (shown before cleaning)

http://i43.photobucket.com/albums/e356/serj22/Motorcraft Boost/IMG_20140708_121750_zps0fafe62d.jpg

The large cirlce, two smaller ones below and the rectangular port at the top. Some kind of vacuum adjustable cylinder is attached to the outside of the three holes. I'm thinking it's some kind of economy device or a type of idle circuit, but nothing I've seen on the carb diagrams I can find say anything about it. I don't know if it will function anywhay since there won't be any vacuum up top for it. I'm debating if I can just leave it there, and seal up the opening (rectangular hole) or if it's needed for something. It had its own choke cover that operated with the normal choke.

http://s43.photobucket.com/user/serj22/media/IMG_20140709_192454_1_zps4d73f655.jpg.html

I'm still trying to figure out the power valve options i have, or if I want to seal it up, and get bigger jets, and operate without, since there will be no vacuum for it to operate. My other thought was I could maybe somehow put a nipple on the power valve cover and run that to the top of the carb hat (pressurized) and it would cause the diaphragm to operate the opposite way, but I'm probably wrong, and that wouldn't do anything.

Another shot of where the powervalve sits, before cleaning. This thing was nasty when I got it.

I am working on making some vent tube extensions and then I'll get on to plugging up different vacuum ports that wont be used so I don't have to rely on a rubber cap for them.

Still waiting on the actual turbo to get here, then I can get my J=pipe made up.

So far I have paid:

Motorcraft 2150: $40

Ebay T3/T4 Turbo new: $120

Blow Off Valve: $10

Wastegate: $10

Manual Boost Controller: $10

Downpipe for turbine: $free

Extra Stock exhaust manifold: $20

The plan is to run my 2bbl Supersix manifold adapted to fit a Motorcraft 2150 - or maybe something else if I determine later, but this is what I have for now. The exhaust I want to run a J-pipe off of to locate the turbo near where the A/C would have been on my motor, and then use the two bolt holes in the block to make a mount to support the turbo to. Then I will plumb the "cold" side directly to a ITB ram hat on top of the carb. I have not decided on an intercooler yet, but it will be a blow-through setup.

I then want to go simple on the oil and go from the filter fitting over to the turbo. Then drain out to a punched hole in the pan. I want to reference the stock fuel pump and hopefully it will meet my minimal boost demands. I will try and get the distributor limited to 18deg total advance since that's what everyone else seems to recommend, to limit the possiblity of detonation. I also will run a wideband sensor so I'm not in the dark with the carb and weather or not it is functioning.

(I got everything but the carb in a package deal off sl6.org. good deal)

So far, I just have a carburetor to start with, that cost me a whopping $30, and rebuilt it for $15, added nitrophyl float, and a seat that allows more flow. I got rid of all the choke peripherals except for the actual choke coil which is the only axis available to make the cam for idle function unfortunately, otherwise I would have removed it all together. Then I filled the choke lever hole, and cut most of the choke riser off.

I got rid of a serious air leak on the bottom that I could not figure out how to adapt, so I J-b'd it and then drilled a couple holes underneath the filler to make it hopefully operate just the same as it did before.

The leak is what you see at the bottom furthest away from the power valve cover:

http://i43.photobucket.com/albums/e356/serj22/IMG_20140712_223451_zps3380b8fa.jpg

No doubt i possibly had to go buy the actual riser, but I figured this would work around it. I saw a thread where someone shoved a rag into the gap to cut the leak. I think this maybe a little more sophisticated. I leveled the area with JB weld in the carb, then knifed it flush and sanded it straight to be at the same level as the carb base. Hopefully it functions. Then I drilled two holes from each side underneath since this was originally a air passage. I was debating if I could just drill between the two barrels and just seal it up, but I figured that may mess something up somehow.

http://i43.photobucket.com/albums/e356/serj22/IMG_20140724_151030_zps98d64868.jpg

I wrote on the cover of the power valve what I drilled the passage to so I could keep track of what I do with it. I'm still trying to figure out how to convert the PV, since it looks similar to a Holley one, but the retainer on the spring is different. -I'm not sure if it would come apart the same to make a BRPV.

I'[m still trying to figure out what this side port is for in the picture (shown before cleaning)

http://i43.photobucket.com/albums/e356/serj22/Motorcraft Boost/IMG_20140708_121750_zps0fafe62d.jpg

The large cirlce, two smaller ones below and the rectangular port at the top. Some kind of vacuum adjustable cylinder is attached to the outside of the three holes. I'm thinking it's some kind of economy device or a type of idle circuit, but nothing I've seen on the carb diagrams I can find say anything about it. I don't know if it will function anywhay since there won't be any vacuum up top for it. I'm debating if I can just leave it there, and seal up the opening (rectangular hole) or if it's needed for something. It had its own choke cover that operated with the normal choke.

http://s43.photobucket.com/user/serj22/media/IMG_20140709_192454_1_zps4d73f655.jpg.html

I'm still trying to figure out the power valve options i have, or if I want to seal it up, and get bigger jets, and operate without, since there will be no vacuum for it to operate. My other thought was I could maybe somehow put a nipple on the power valve cover and run that to the top of the carb hat (pressurized) and it would cause the diaphragm to operate the opposite way, but I'm probably wrong, and that wouldn't do anything.

Another shot of where the powervalve sits, before cleaning. This thing was nasty when I got it.

I am working on making some vent tube extensions and then I'll get on to plugging up different vacuum ports that wont be used so I don't have to rely on a rubber cap for them.

Still waiting on the actual turbo to get here, then I can get my J=pipe made up.