Nice!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Slant Six Roadster Build

- Thread starter thebearded1

- Start date

-

If you go with the outside parking brake there's room for even more rat rod coolness. You'll need to lock it somehow to keep people from effin with it like you know they will. I'd find the biggest, oldest lookin padlock I could find for it. lol

That's badass man! It's in the wind! Literally! lolTook it on a shakedown run this evening. Unfortunately a lot of wind noise so you can hear the mighty slant haha. Hopefully will have headlights and seatbelts in this week. Maybe shocks too!

https://youtube.com/shorts/MHB0s_EzmJo?feature=share

Good Rundown, Thanks for sharing!

Any chance you would drive it up to Union Bridge Maryland?

There is an open house / Car show at my friend's Resto Shop on october 22nd.

Primarily British Cars but the open house is well... open.. I plan on being there in my '64 Dart.

Open House 2022 – Vintage Restorations Limited

Cheers!

Greg

Any chance you would drive it up to Union Bridge Maryland?

There is an open house / Car show at my friend's Resto Shop on october 22nd.

Primarily British Cars but the open house is well... open.. I plan on being there in my '64 Dart.

Open House 2022 – Vintage Restorations Limited

Cheers!

Greg

thebearded1

Well-Known Member

Good Rundown, Thanks for sharing!

Any chance you would drive it up to Union Bridge Maryland?

There is an open house / Car show at my friend's Resto Shop on october 22nd.

Primarily British Cars but the open house is well... open.. I plan on being there in my '64 Dart.

Open House 2022 – Vintage Restorations Limited

Cheers!

Greg

We'll see if i have everything done by then and enough test runs for that trip, it'd be about 2-2.5 hours from me. Once i get a roll bar added i'd like to be able to go to the mason dixon slant six race for fun

Sounds good sir!We'll see if i have everything done by then and enough test runs for that trip, it'd be about 2-2.5 hours from me. Once i get a roll bar added i'd like to be able to go to the mason dixon slant six race for fun

Make sure your helmet and proper sfi harnesses are in date so you do not get dinked at tech.

Good luck and have fun with it!

cudavert

DARTAHOLIC

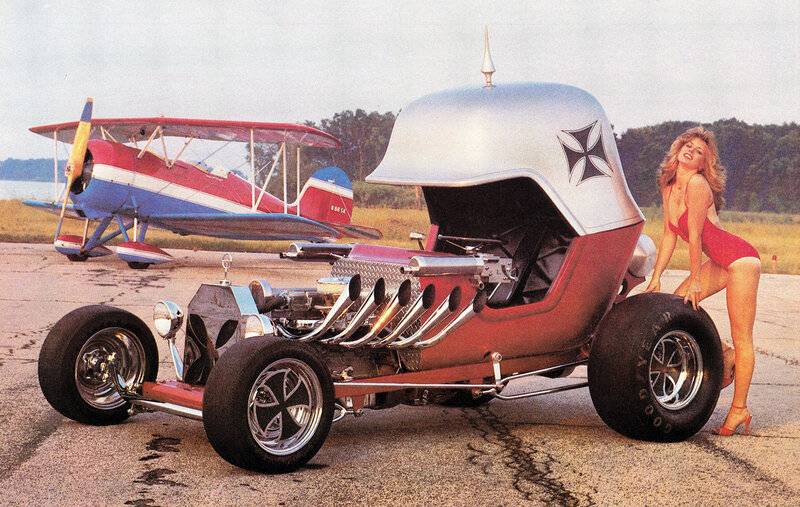

I've always loved the idea of an inline 6 roadster, ever since I built this model as a kid:

thebearded1

Well-Known Member

Sounds good sir!

Make sure your helmet and proper sfi harnesses are in date so you do not get dinked at tech.

Good luck and have fun with it!

Will do that's why I am waiting to buy all that stuff once the roll bad is officially done haha

thebearded1

Well-Known Member

Doing boring stuff like wiring the headlights today and trying to check over little things but figured I would share my "gas gauge" I made. The fuel tank does not have a hole for a sender so that wasn't an option besides welding a place for it. That would also mean more wires and it would take away from the old race car look I'm going for. I had an old tractor gas cap I found in a barn so I drilled it out to fit a brass compression fitting. I had to machine (files and vice haha) the compression fitting a little to get.it to fit perfectly. I also smoothed out the inside of the compression fitting. Then I used a piece of aluminum tubing and attached a fuel sender to the end with holes and copper wire. This way the aluminum tube will slide up and down to show me roughly how full or empty the tank is. I topped off the aluminum tube with a piece of heat shrink to keep any junk from going into the hole. I had to put the float at the funny angle so I could fit everything into the gas filler neck. I got the idea from a plunger style cap used on a tractor. The cork float was on a lever at the bottom. That unit cost $125 before covid so I wasn't going that route haha. I will probably add some marks to it once I fill the tank and get to 3/4 1/2 and 1/4. It binds a little bit if the float and aluminum rod aren't perfectly straight up and down but this car will be bumpy enough to realign it as needed haha. Sorry I can't find the photos I took when I was making it.

Helme

Harnesses for 2 years.

Good work on your fuel sender unit.

I like it!

Helmets usually are good 5-10 years for the snell ratings.Will do that's why I am waiting to buy all that stuff once the roll bad is officially done haha

Harnesses for 2 years.

Good work on your fuel sender unit.

I like it!

thebearded1

Well-Known Member

Helme

Helmets usually are good 5-10 years for the snell ratings.

Harnesses for 2 years.

Good work on your fuel sender unit.

I like it!

Thanks! I have a regular sealed fuel cap for track use. I will probably try running the car at Maryland International Raceway for their Mopar day or at least bring it for the show and ask a tech guy to come tell me what i would need to make some passes before i make something and find out it's not enough. MDIR is IHRA sanctioned and Mason Dixon is NHRA sanctioned so not sure how different the tech requirements would be.

thebearded1

Well-Known Member

Progress has been slow. I went to drive it to my buddy's house so we could weld the headlight brackets on and brackets for the rear shocks but once the car hit above 40 mph the front tires started bouncing like basketballs so i went back home as the drive is on 55 mph roads (everyone doing 65+) and normally takes 30 minutes. I rechecked the toe in on the front tires and adjusted that to about an 1/8" toe in. I also ordered some steel and am going to build a set of friction shocks for the front. The car never bounced before with the previous owners friction shock setup but it was god awful looking and questionably built haha.

I will probably trailer the car over to my buddy's place once i'm ready but unfortunately my 2022 Ram with under 500 miles is in the shop with a backfire through the intake idling issue.

I will probably trailer the car over to my buddy's place once i'm ready but unfortunately my 2022 Ram with under 500 miles is in the shop with a backfire through the intake idling issue.

mygasser

Well-Known Member

how much caster is the front end set up with? if it's not enough that can give symptoms like you describe. may be worth checking.

neil.

neil.

thebearded1

Well-Known Member

Forgot to mention that, I have it set at about 7 degrees back. That's what I saw on the t bucket forums and the hamb for setting up the front endhow much caster is the front end set up with? if it's not enough that can give symptoms like you describe. may be worth checking.

neil.

duster 344

Well-Known Member

That thing is so cool , it’s really cool to see what someone can do with a slant six

thebearded1

Well-Known Member

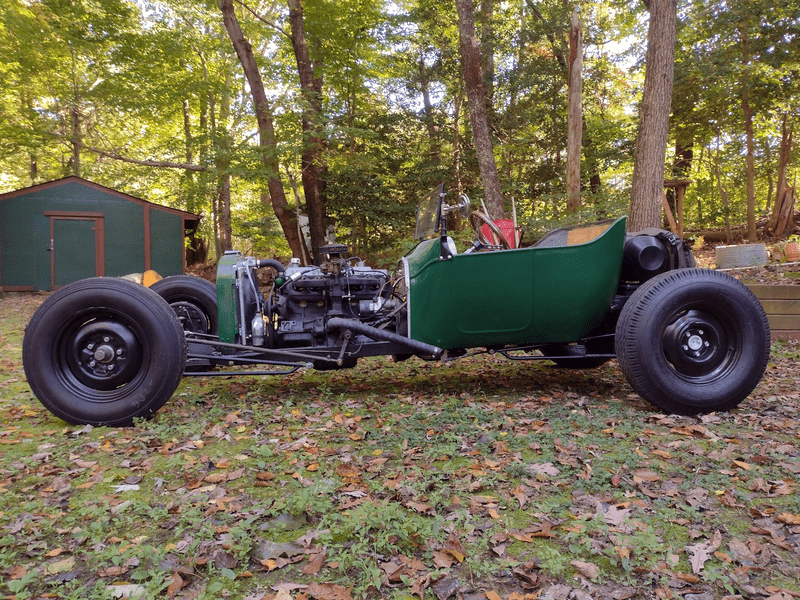

Some small updates...

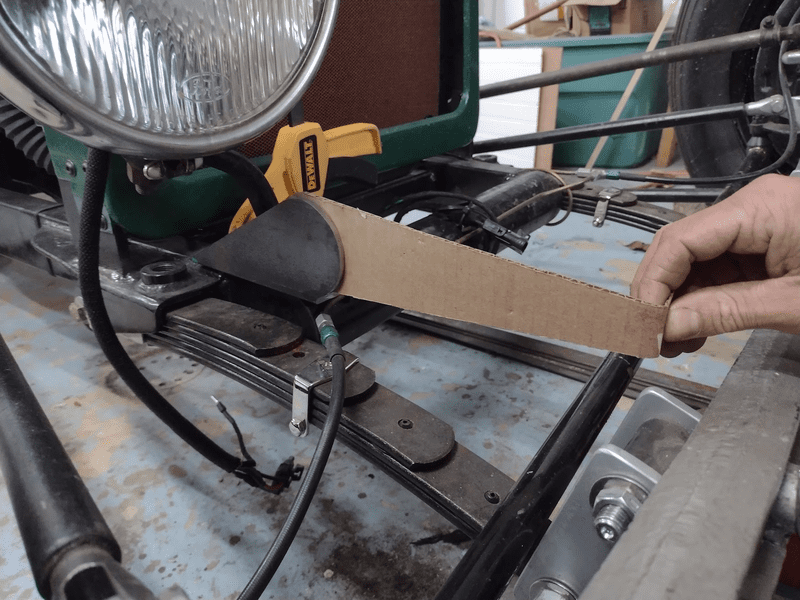

I'm currently making some friction shocks for the front. The bracket on the car will be bolted down with the headlights. On either side of the vertical piece will be 2 disks i'm going to cut out of 1/4" thick UHMW plastic, then over those will be 2 shock arms that extend toward the axle. A bolt with a valve spring and lock nut will secure it all together. The spring helps keep tension on the friction disks as they wear down. The plastic has less friction than other options used (wood, rubber, leather, clutch disk material) but this allows for a smoother movement of the shock.

I'm going to weld on a tab to the spring shackle and the shock arm will attach with a short link made out of a male and female threaded heim joint. To dress up the shocks arms I will probably add some speed holes and paint the inside of the holes green and the rest silver.

I found some 16x4 front wheels for the car and mounted some tires I already had. Looks pretty good, next set of tires i may go slightly smaller, these are 6.00-16.

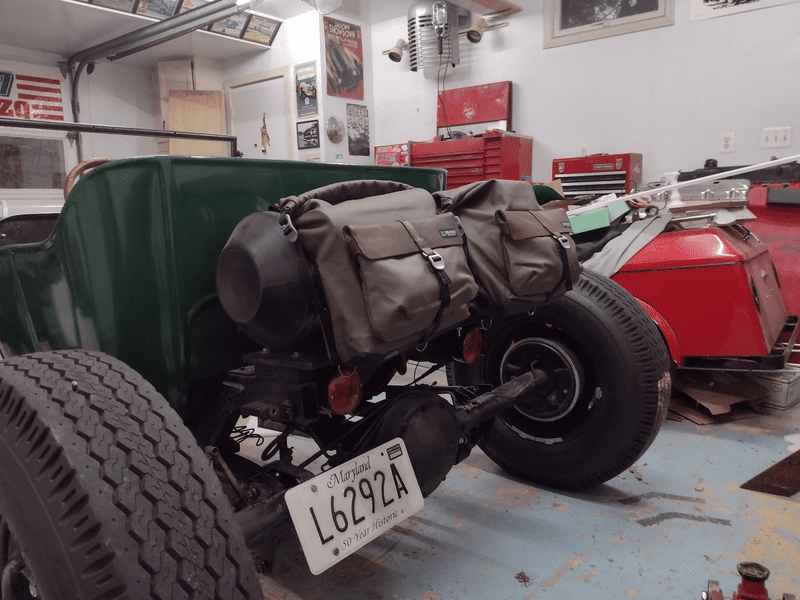

I also found a neat set of motorcycle paniers for the rear tank for extra storage

I'm currently making some friction shocks for the front. The bracket on the car will be bolted down with the headlights. On either side of the vertical piece will be 2 disks i'm going to cut out of 1/4" thick UHMW plastic, then over those will be 2 shock arms that extend toward the axle. A bolt with a valve spring and lock nut will secure it all together. The spring helps keep tension on the friction disks as they wear down. The plastic has less friction than other options used (wood, rubber, leather, clutch disk material) but this allows for a smoother movement of the shock.

I'm going to weld on a tab to the spring shackle and the shock arm will attach with a short link made out of a male and female threaded heim joint. To dress up the shocks arms I will probably add some speed holes and paint the inside of the holes green and the rest silver.

I found some 16x4 front wheels for the car and mounted some tires I already had. Looks pretty good, next set of tires i may go slightly smaller, these are 6.00-16.

I also found a neat set of motorcycle paniers for the rear tank for extra storage

thebearded1

Well-Known Member

I made some progress on the friction shocks today. The part that attaches to the frame is made of 2x3 unequal angle iron. It will be bolted to the frame with the headlights. I still need to trim down this mount that is sticking beyond the frame. The material in-between the shock arms are discs that I cut out of a sheet of UHMW plastic. This material had less static friction so it will result in a smoother operation. The slant six valve spring keeps pressure on the discs even if they start to wear down. This will still require regular checks with a torque wrench. Thanks to @Charrlie_S for sending me the retainers. They work perfect as a washer for the nut to rest on and keep the spring centered. My buddy will weld a tab onto the leaf spring shackle and the heim joint shock links will attach there. I will probably add some speed holes to the shock arms later on.

Last edited:

thebearded1

Well-Known Member

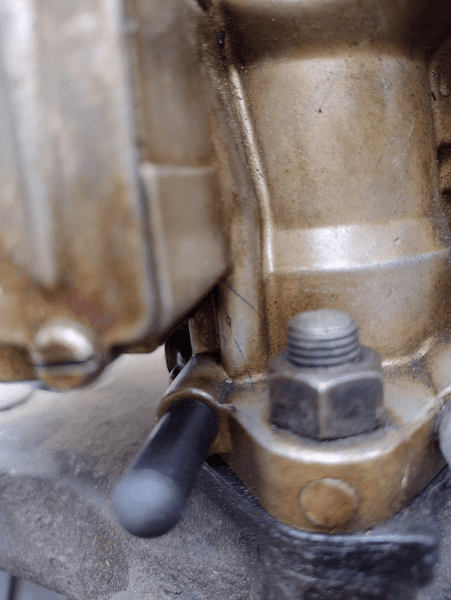

Idle video before i noticed the cracked carb body

thebearded1

Well-Known Member

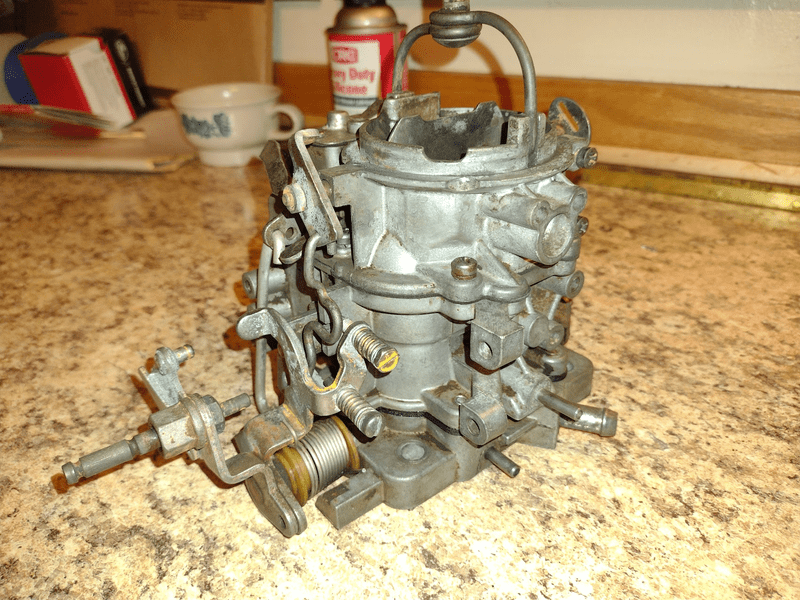

After finding the cracks in the body of my Holley 1920...

I rebuilt a Holley 2280 that I had got a while ago. Thanks to Mike's Carburetor Parts and an ice cube tray it was easy.

I wasn't able to clean the body in all the corners but it was clean where it counts. Now i need to decide what color to paint the intake then I can try it out.

I rebuilt a Holley 2280 that I had got a while ago. Thanks to Mike's Carburetor Parts and an ice cube tray it was easy.

I wasn't able to clean the body in all the corners but it was clean where it counts. Now i need to decide what color to paint the intake then I can try it out.

Love the ice cube tray idea!

thebearded1

Well-Known Member

Thanks it was the first auto carb i have rebuilt so I wanted to keep all the parts organizedLove the ice cube tray idea!

I moved the labels to the side of the tray and added simple green to each cup to soak the parts

thebearded1

Well-Known Member

Impatiently waiting for my Remflex gaskets to arrive

sireland67

Well-Known Member

I really like the color you picked out.

Are those valve sprAngs you're using on the friction shocks?

-