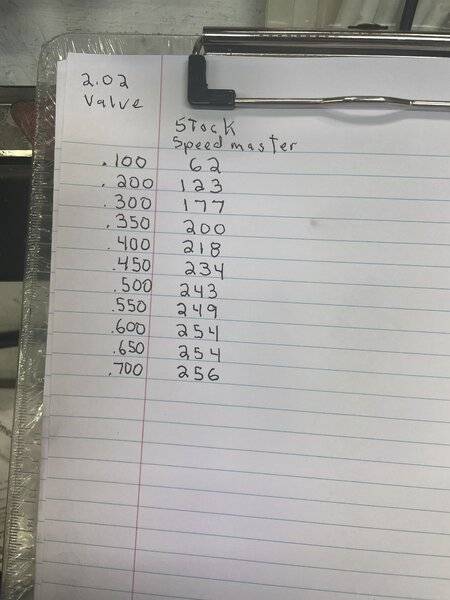

It’s been a long time since I flow tested a stock Edelbrock head and one ported but retaining the stock sized valves (2.02). There was some interest in head tubing yesterday so I’ll touch on that again. After I finished flow testing the TrickFlow head with Victor340 and Wilson spacer I removed it from the bench and grabbed two assembled Speedmaster heads. This is the first set I bought assembled and the springs, retainers, and keepers look pretty nice. What I did notice was that there were five what look like hardened valve spring shims under each spring. They measure close to .142 on the exhaust and .132 on the intake valves. Then I bolted one on the flowbench and did a flow test. Numbers posted. I with update with ported numbers from the same port after a five angle intake side valve job and porting work is finished. Then I drilled the two common wall head bolts out to 9/16 and hand drilled the four pushrod holes out to 17/32. Because of the way the pushrod holes are cut they are easier to drill from the finished (head gasket) side then flip the head over and drill from the top. One head will take four 17/32 and two 9/16. Pictures shows it takes very little epoxy to do one head at a time. Test fit all pieces before applying epoxy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speedmaster heads revisited.

- Thread starter pittsburghracer

- Start date

-

Ironracer

Gearhead

Man, Awesome Work!

After the epoxy dries I use a chamfer bit on the head bolts holes that were tubed and the pushrod holes on the machined side. I use a carbide burr later to drums up the top of the pushrod tubes. Tomorrow this head will look a lot different.

Ironracer

Gearhead

I may have to search for some of your other cylinder head upgrade posts. If I recall correctly you're moving to pushrods to make room for more porting? And I guess you're drilling out the holes in the heads to put bigger studs in the Box for more clamping force or am I mistaken about that that's just a wild guess by the way? Hey, your way out of my league here, Brother! I'm just trying to figure it out so I can wrap my, head around it! Lol

I may have to search for some of your other cylinder head upgrade posts. If I recall correctly you're moving to pushrods to make room for more porting? And I guess you're drilling out the holes in the heads to put bigger studs in the Box for more clamping force or am I mistaken about that that's just a wild guess by the way? Hey, your way out of my league here, Brother! I'm just trying to figure it out so I can wrap my, head around it! Lol

No this is just refreshing the guys on tubing the existing holes so you can port over and just touch the tubing so you can use all the available area in the port. When finished it will use the same rockers as stock heads. You will see later in the week how much area and cfm I gain.

Ironracer

Gearhead

Yessir, Thank You! So I take it, the tubing is reinforcing the holes...?No this is just refreshing the guys on tubing the existing holes so you can port over and just touch the tubing so you can use all the available area in the port. When finished it will use the same rockers as stock heads. You will see later in the week how much area and cfm I gain.

No it’s letting me port over to the tubing to take all available area.Yessir, Thank You! So I take it, the tubing is reinforcing the holes...?

Don’t get ahead of yourself or me. It’s easier to understand after you see the processYessir, Thank You! So I take it, the tubing is reinforcing the holes...?

Is the flow on the stock Speedmasters compatible to a stock Edelbrock ?

replicaracer43

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 6,051

- Reaction score

- 7,867

Once again, EXCELLENT tech posts, really appreciate you sharing!

Ironracer

Gearhead

So it's actually a sleeve, I'm thinking. I'll just be patient and tune into the entire process, I've actually read quite a bit of your stuff, just bad memory. LolNo it’s letting me port over to the tubing to take all available area.

So it's actually a sleeve, I'm thinking. I'll just be patient and tune into the entire process, I've actually read quite a bit of your stuff, just bad memory. Lol

If you want to get a head start or a quick review I have several posts on these here. This is just to freshen things up. Lol.

Speedmaster head thread index

Is the flow on the stock Speedmasters compatible to a stock Edelbrock ?

I see a little more only because the Speedmaster castings are so much nicer.

Ironracer

Gearhead

Thank you! I'll check em out, just wanting to learn something on an otherwise wasted day. I've always thought if you don't learn the littlest thing, even on the worst day.....If you want to get a head start or a quick review I have several posts on these here. This is just to freshen things up. Lol.

Speedmaster head thread index

33IMP

Well-Known Member

I never thought I'd ever see something like this in print from a respected source. Really, it's a shame.I see a little more only because the Speedmaster castings are so much nicer.

I never thought I'd ever see something like this in print from a respected source. Really, it's a shame.

If you would see some of the Edelbrock heads I’ve been getting to port it would bring a tear to your eyes. I swear the plunge cutter they use on the port entrance is the same one from 40 years ago. Terrible work.

33IMP

Well-Known Member

I've got some new in box rpm's from many years ago that are pretty nice, and a pair of Victor maxwedges from about four years ago, that aren't bad. (Big block stuff)

I also gambled on an unbelievable black Friday deal on some speedmaster bbc stuff, and was surprised how nice everything looked.

I also have an edelbrock Sixpack manifold..... and the port mouths at the head, and the core shift under the carbs is horrible!

I also gambled on an unbelievable black Friday deal on some speedmaster bbc stuff, and was surprised how nice everything looked.

I also have an edelbrock Sixpack manifold..... and the port mouths at the head, and the core shift under the carbs is horrible!

I've got some new in box rpm's from many years ago that are pretty nice, and a pair of Victor maxwedges from about four years ago, that aren't bad. (Big block stuff)

I also gambled on an unbelievable black Friday deal on some speedmaster bbc stuff, and was surprised how nice everything looked.

I also have an edelbrock Sixpack manifold..... and the port mouths at the head, and the core shift under the carbs is horrible!

The Speedmaster sloppiness is in the bowl under the seat and short turn. East fix but most guys aren’t going to disassemble their heads let alone take a grinder to them.

Ironracer

Gearhead

I got hired at a Foundry pulling the hot castings with green sand off the belt as they came out.... this was a small place where the biker in charge of the shop and a car guy that owned it they mainly did small runs of custom manifolds and stuff like that for old hot rodsI've got some new in box rpm's from many years ago that are pretty nice, and a pair of Victor maxwedges from about four years ago, that aren't bad. (Big block stuff)

I also gambled on an unbelievable black Friday deal on some speedmaster bbc stuff, and was surprised how nice everything looked.

I also have an edelbrock Sixpack manifold..... and the port mouths at the head, and the core shift under the carbs is horrible!

Ironracer

Gearhead

I had to spend $120 on a valve spring compressor to take my own heads pull them apart and put them back apart. I destroyed two or three rentals locally and finally gave up and bought one! Lol next step is the grinder Brother, except I actually need something to cut on... my 340 heads are maxed out and the big block heads I got could use work in the exhaust (it looks like a stock port opening) but the intake is openThe Speedmaster sloppiness is in the bowl under the seat and short turn. East fix but most guys aren’t going to disassemble their heads let alone take a grinder to them.

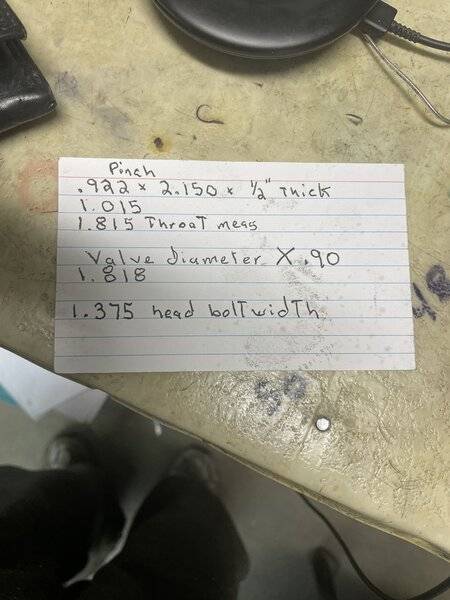

Ok guys I won’t be answering many questions today as this head will be totally roughed in so I gotta keep at it. The throat dimension is 1.815 from Speedmaster. My target is 89-90% of valve size so with a 2.02 valve target would be 1.818 so we are good to go. That’s one reason I love going with a 2.055 valve so I can cut the angles on my seat machine. With a 2.02 seat I use my Neway cutters and hand cut my 70-60-45-30-15 on the intake side. I don’t calculate port sizing as I go by airspeed on my bench. But for the numbers guys stock sizing at the pinch is .922 wide by 2.150 high and the pinch is over 1/2 inch because the port continues to move into the port as you port over to the tubes I installed. After just porting over to the tube without touching the common wall yet it measures 1.015 so I gained .093 width so far at “the pinch”. If you look closely you can see where I kissed the tube to know that’s all I can get.

Next up I will be attacking the ugly head bolt bulge. Across the port it now measures 1.375 but I will have a lot more area at the most needed spot in these heads in an hour. Hears a picture of the ugliness from the factory on the shortside heading into the valve.

moparstud440

Well-Known Member

great informative detail post as always.

Ok all four head bolt bulges are gone and the wall is a lot straighter. It will get straightened more as I go along. Pinch now went from .922 up to 1.015 to 1.045. I will gain more as I continue to straighten the wall. Head bolt bludge measured 1.375 and it’s now 1.580 porting over to my tubes. I will gain more when I start on the other side of the runner but .200 is a lot of “prime” area. That is my Ribeye cut of the whole port.

Next up I’m going to attack the roof and straighten this mess up some.

-