What else can I check on my own?

Or is this enough to determine course of action?

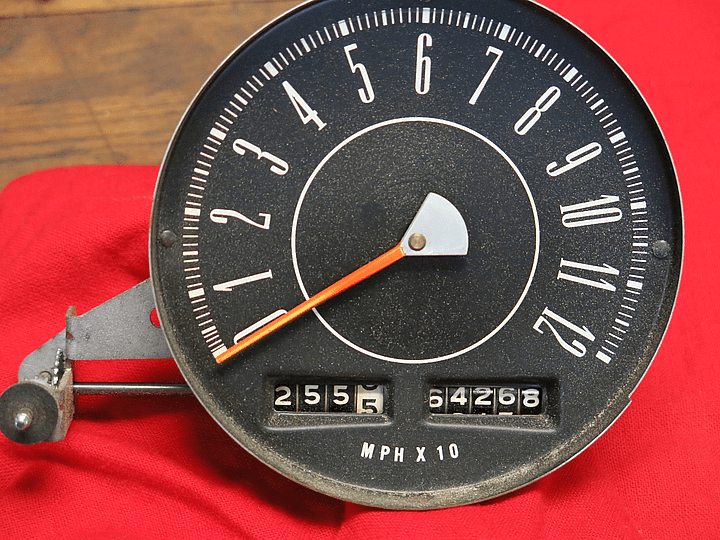

67 Barracuda 120 mph Speedometer with trip odo.

Here's are the symptoms and what I've checked so far:

This speedometer occassionally was bouncing hard (jittery). Sometimes its completely fine. I have removed, cleaned and relubed the cable a few times. Coming back from central Pa this fall,going approx 50 mph it was making a little growl every 15 or 20 seconds. Last week had it out - nothing audible at all. ( I did try @pishta idea of using a siringeto place little drop of oil in the brass cup. I'm still not sure if there is a pinhole at the bottom to actually let any oil through.) I might have just straightened/tightened the cable housing enough to resolve the noise.

Since the instrument panel had to come out anyway, it was time to look at this thing.

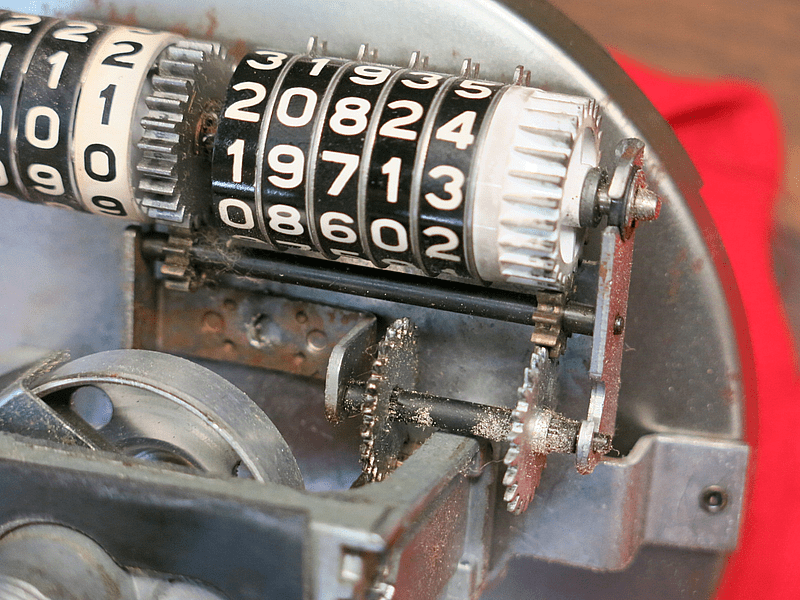

First test was this.

No movement of the needle

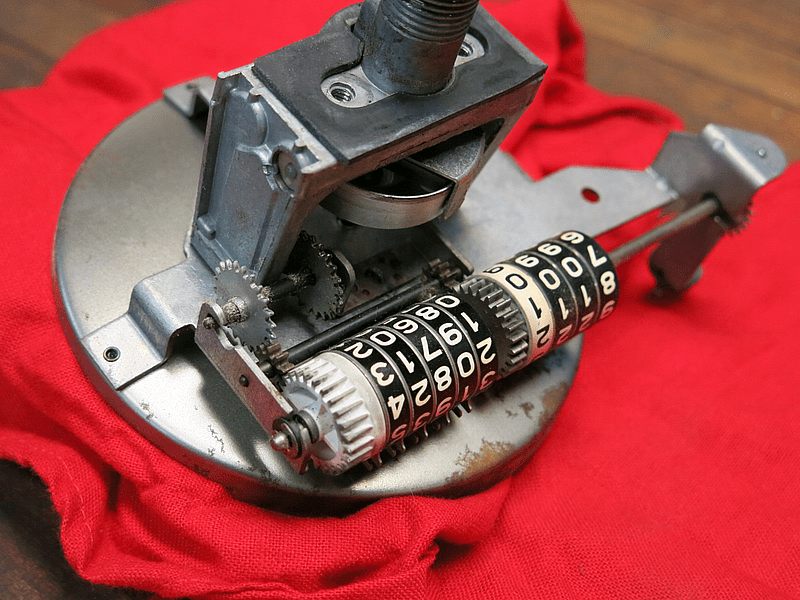

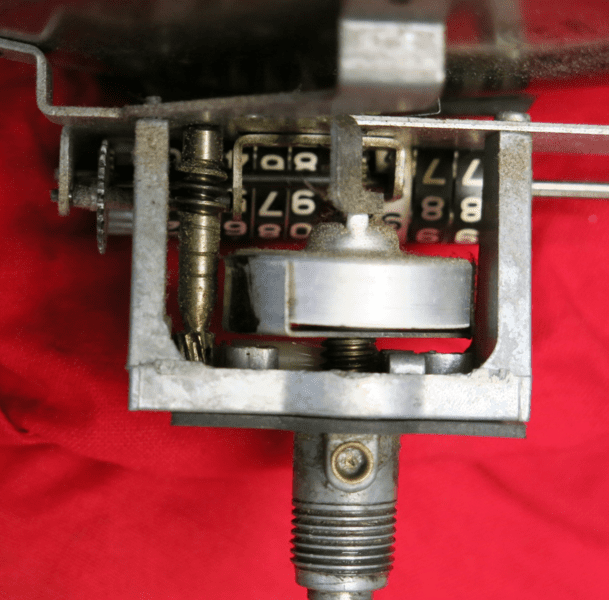

Visually, other than dust and dirt, I don't see any obvious wear in the gearing.

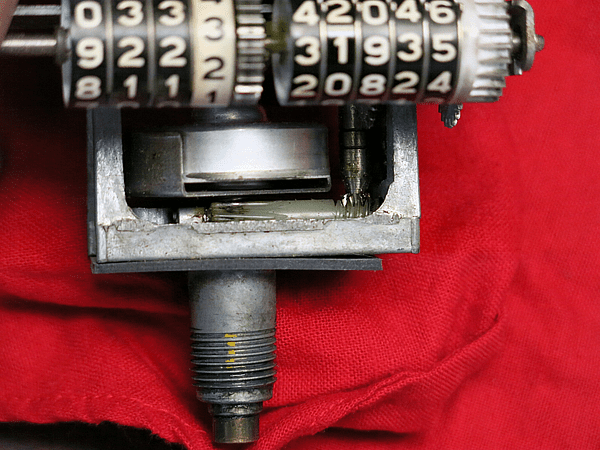

Evaluating the photos it does look like the shell may be getting kissed. Yes?

Or is this enough to determine course of action?

67 Barracuda 120 mph Speedometer with trip odo.

Here's are the symptoms and what I've checked so far:

This speedometer occassionally was bouncing hard (jittery). Sometimes its completely fine. I have removed, cleaned and relubed the cable a few times. Coming back from central Pa this fall,going approx 50 mph it was making a little growl every 15 or 20 seconds. Last week had it out - nothing audible at all. ( I did try @pishta idea of using a siringeto place little drop of oil in the brass cup. I'm still not sure if there is a pinhole at the bottom to actually let any oil through.) I might have just straightened/tightened the cable housing enough to resolve the noise.

Since the instrument panel had to come out anyway, it was time to look at this thing.

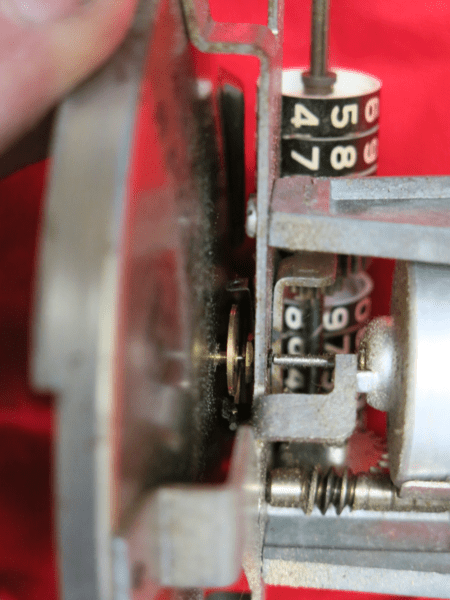

First test was this.

There is a tiny amount of for aft movement (about 1/64 or even less).in a leaned back position, resting on the input shaft. Wear in the instrument causes the magnets to draw the needle away from '0'. If the needle lifts to more than 5 mph, continue shopping for better.

When new, bias force on the input shaft wouldn't move the needle at all.

No movement of the needle

Visually, other than dust and dirt, I don't see any obvious wear in the gearing.

Evaluating the photos it does look like the shell may be getting kissed. Yes?

Last edited: