Any time this comes up, I always say the shaft is junk. Those pins are in there for a reason, so the shaft does not instantly impale you to the back seat in an accident. Think about it - the shaft is essentially connected directly to the K member (chassis) through the steering box. If the car is in a severe enough impact and things start to buckle, imagine what the shaft will be doing if it's solid - going straight through your chest. The pins give it enough cushion to absorb the impact. In addition, once it's collapsed, it will move up and down inside the column in relation to where its mounted. Not good!

To my knowledge, there is no way to repair it once its been collapsed. Guys have tried to use hot glue, whittled down nylon bolts etc. I think the OE material was delrin or something like that. It was precisely injected so duplicating it would be pretty tough. You'd need to test it to see how strong it is and repeat it over and over until you were sure that it was right.

I recently rebuilt the column in my Duster. The shaft that was in the car was collapsed. Someone had put a metal tab over the bottom end where it meets the upper half and bent a piece of metal inwards to keep it from moving around. The pins were totally gone and I could pull it apart with my hands. I was not happy. I had another shaft so I used that.

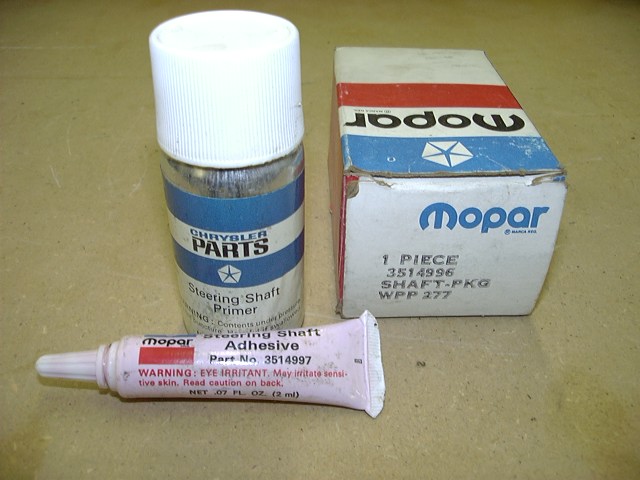

I would like to figure out a way to fix 'em, I have two collapsed shafts. There used to be a genuine Mopar repair kit but its long gone.