Among my other projects such as 3d printing new tail lights, a gauge panel and dashboard, BMW seats, etc...I've been working on something I'm calling Project Blackstone.

Goal: to be able to present either an "old school" radio, or a modern touchscreen, at any given moment in my 66 Dart.

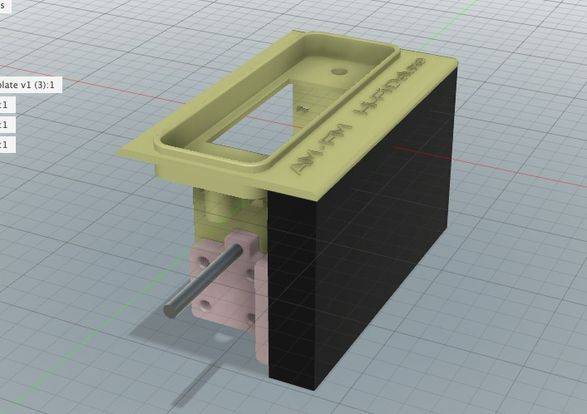

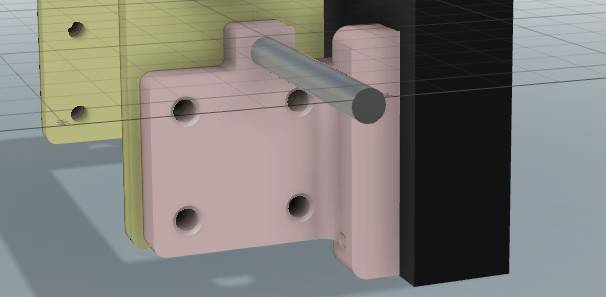

Method: An in dash module that can pivot brackets holding an old school radio face and a touchscreen, to show one or the other

This will be based partially on ignition state (acc or ignition on = touchscreen, acc or ignition off = old radio), but will also involve a switch to change on command.

I am using a Pioneer head unit with 6.8" touchscreen that is modular, meaning the screen is connected to the "guts" via a data cable. The old school radio is a Retrosound faceplate and knobs.

As I said the intention is for this to be a drop in complete module, meaning I just cut a hole in the dashboard and attach it. Loss of vent controls is expected (I'm shaving the cowl vent anyway).

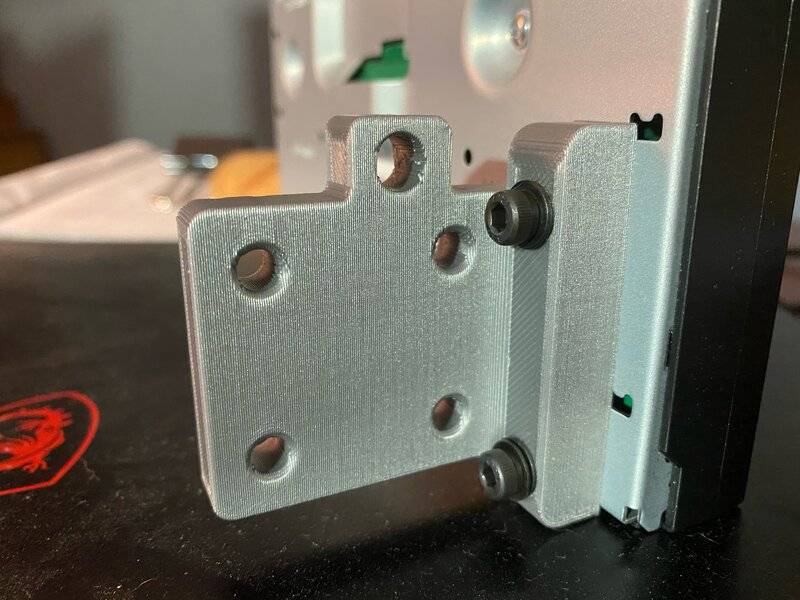

I'm over halfway there in the design department, with the bracketry created for holding the two radio faces in register with each other and having a pivot point. Still to do: Settle on the servo motor to be used, design brackets to support it and connect to the radio brackets, and design the overall housing that keeps it together. Next month the Dart comes home, and summer is a great time to work on this project, so I'm hoping to complete the module (except for control) by September. The first of the brackets has been printed, and I believe came out as usable parts, but I'm not printing anything else until I'm done designing and can verify measurements when the car gets here.

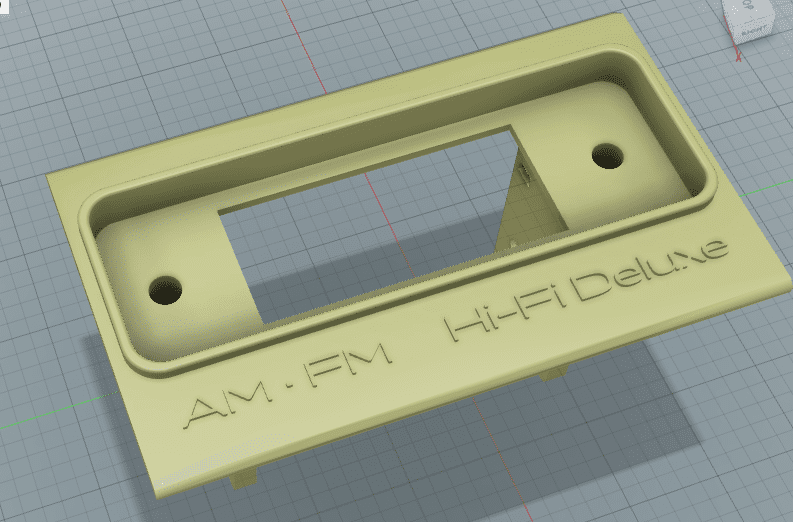

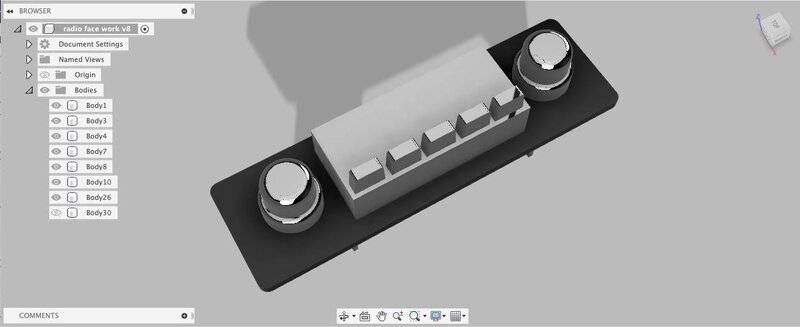

I also modeled the retrosound radio face as a fun exercise. If I can figure out the pinology of the retrosound face, I'll give it voltage so that if the car is on and I switch to old school radio mode, the radio face is backlit. The face has an overlay sticker of radio stations, so it might look cool.

Goal: to be able to present either an "old school" radio, or a modern touchscreen, at any given moment in my 66 Dart.

Method: An in dash module that can pivot brackets holding an old school radio face and a touchscreen, to show one or the other

This will be based partially on ignition state (acc or ignition on = touchscreen, acc or ignition off = old radio), but will also involve a switch to change on command.

I am using a Pioneer head unit with 6.8" touchscreen that is modular, meaning the screen is connected to the "guts" via a data cable. The old school radio is a Retrosound faceplate and knobs.

As I said the intention is for this to be a drop in complete module, meaning I just cut a hole in the dashboard and attach it. Loss of vent controls is expected (I'm shaving the cowl vent anyway).

I'm over halfway there in the design department, with the bracketry created for holding the two radio faces in register with each other and having a pivot point. Still to do: Settle on the servo motor to be used, design brackets to support it and connect to the radio brackets, and design the overall housing that keeps it together. Next month the Dart comes home, and summer is a great time to work on this project, so I'm hoping to complete the module (except for control) by September. The first of the brackets has been printed, and I believe came out as usable parts, but I'm not printing anything else until I'm done designing and can verify measurements when the car gets here.

I also modeled the retrosound radio face as a fun exercise. If I can figure out the pinology of the retrosound face, I'll give it voltage so that if the car is on and I switch to old school radio mode, the radio face is backlit. The face has an overlay sticker of radio stations, so it might look cool.

Last edited: