You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torsion bar remove tool

- Thread starter nodemon

- Start date

-

The ones I use can be found at Lowes on the hammer isle lol

There ya go!I built a tool and then one still wouldn't come out. It was easier to cut them off and buy used ones for $100.

My old Mopar needed a new engine, so I just bought one that didn't!

ragtopfury

Well-Known Member

Speaking of stuck T-bars.... what method do you use when they don't want to come out? And yes, I removed the clip, backed the adjusters all the way off.

Apply heat to the T-bar socket in the frame?

Apply heat to the T-bar socket in the frame?

Disconnect the strut rod both front and rear front first. Then remove the nut on the front of the control arm pin.

With the torsion bar adjuster backed out and the clip removed from the rear of the torsion bar. Now you should be able to hit the control arm pin and the control arm back out of the K-member thus moving the torsion bar back out of the cross member.

Once this is done and the bar is out of the cross member tap the rear of the control arm front off of the torsion bar. Use a soft hammer or brass drift to prevent damage if your swinging like a wildman.

With the torsion bar adjuster backed out and the clip removed from the rear of the torsion bar. Now you should be able to hit the control arm pin and the control arm back out of the K-member thus moving the torsion bar back out of the cross member.

Once this is done and the bar is out of the cross member tap the rear of the control arm front off of the torsion bar. Use a soft hammer or brass drift to prevent damage if your swinging like a wildman.

Protect the threads!Use a soft hammer or brass drift to prevent damage if your swinging like a wildman

Kendog 170

Let the boy go !

I grabbed an old gooseneck from a bmx bike and used longer bolts to clamp on and hit with a hammer.

ragtopfury

Well-Known Member

Sounds good, except the lca pin is spinning with the nut.....grrrr

Tsully

Well-Known Member

If you’re on Facebook look this guy up… he makes a tool to remove them.

67Dart273

Well-Known Member

Or pry on the lower arm after doing this, with such as a 2x4Disconnect the strut rod both front and rear front first. Then remove the nut on the front of the control arm pin.

With the torsion bar adjuster backed out and the clip removed from the rear of the torsion bar. Now you should be able to hit the control arm pin and the control arm back out of the K-member thus moving the torsion bar back out of the cross member.

Once this is done and the bar is out of the cross member tap the rear of the control arm front off of the torsion bar. Use a soft hammer or brass drift to prevent damage if your swinging like a wildman.

Mancini racing removal tool... lots of penetrating oil and diligence

I went through three sets of bolts but won the war

I went through three sets of bolts but won the war

dano

Evil Handy Man

I have this one. It works but it doesn't play well with Doug's headers.Mancini racing removal tool... lots of penetrating oil and diligence

I went through three sets of bolts but won the war

There is no reason to buy, rent or make a torsion bar removal tool.

As already described, remove everything from the lower control arm (spindle, shock, strut rod, sway bar if present, etc). Remove the nut off the LCA pivot shaft. Remove the torsion bar clip. Use a pry bar between the K frame and the LCA to pry the LCA back, the torsion bar will move with it until the hex end drops out of the socket.

You can also use a dead blow hammer on the LCA if it needs more motivation, but the pry bar generally works best. You can apply far more force this way than with any torsion bar removal tool. I bought one of those useless trinkets before I knew better, they're totally unnecessary.

Never grab a torsion bar you want to reuse with a set of vice grips. If you put teeth marks in the bar it creates hardened metal that will crack when torsion is applied again. If you're gonna do that, you might as well just cut the bars with a cut off wheel.

It's a LOT easier to use the LCA to push the bars back using the K as your fulcrum.

As already described, remove everything from the lower control arm (spindle, shock, strut rod, sway bar if present, etc). Remove the nut off the LCA pivot shaft. Remove the torsion bar clip. Use a pry bar between the K frame and the LCA to pry the LCA back, the torsion bar will move with it until the hex end drops out of the socket.

You can also use a dead blow hammer on the LCA if it needs more motivation, but the pry bar generally works best. You can apply far more force this way than with any torsion bar removal tool. I bought one of those useless trinkets before I knew better, they're totally unnecessary.

Never grab a torsion bar you want to reuse with a set of vice grips. If you put teeth marks in the bar it creates hardened metal that will crack when torsion is applied again. If you're gonna do that, you might as well just cut the bars with a cut off wheel.

It's a LOT easier to use the LCA to push the bars back using the K as your fulcrum.

I guess I know how to use them without leaving marks.. I've seen more scored up hamming away with one of those removal tools.Never grab a torsion bar you want to reuse with a set of vice grips.

plyman

Active Member

Went to a logging supply store and bought a large cable clamp, worked well and cheap too.

Years ago in my mechanic apprentice days, our front end guy taught me to do as @Oldmanmopar and @72bluNblu described. I learned to use the pry bar first on the LCA and then the hammer if needed. He told me to never clamp onto the T-bar with anything unless i was replacing them.

I agree with not knicking the tortion bars and the verious methods outlined here to remove the bar.

and quite frankly that would be the way I would go first IF I needed to remove the front suspension.

but if I only needed to remove the T bar I expect the FSM procedure WITH THE RIGHT TOOLS would be the way I would go. I suspect a couple pieces of belt thickness leather between bar and clamp would work well.

i assume the OEM tool is not knurled on the inside.

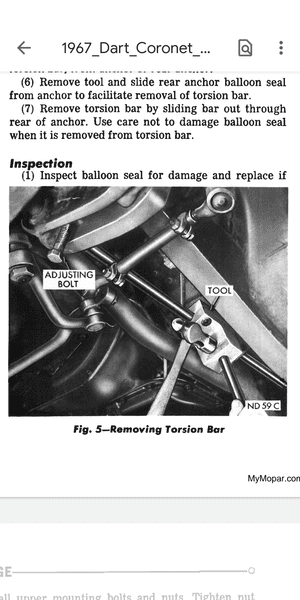

FSM

Clamp on tool

Repair damaged surface

and quite frankly that would be the way I would go first IF I needed to remove the front suspension.

but if I only needed to remove the T bar I expect the FSM procedure WITH THE RIGHT TOOLS would be the way I would go. I suspect a couple pieces of belt thickness leather between bar and clamp would work well.

i assume the OEM tool is not knurled on the inside.

FSM

Clamp on tool

Repair damaged surface

I'v got the official torsion bar removal tool from the Miller Special Tools Company, purchased back in the dinosaur days, when tools like this were readily available for purchase.

In all these decades i rarely have used it.

I just put a big pry par up in the cross member area and pry rearward, getting the LCA out, with the torsion bar.

But getting them out is easy for me as I'm, working on cars out here in Commiefornia, Arizona, that aren't from the rust bucket states, here in the USA.

I have loaned out that tool probably more times than i personally have used it myself.

And a few times i got it back with the **** being beat out of it, but that's what the tool is for if you got a stubborn torsion bar.

In all these decades i rarely have used it.

I just put a big pry par up in the cross member area and pry rearward, getting the LCA out, with the torsion bar.

But getting them out is easy for me as I'm, working on cars out here in Commiefornia, Arizona, that aren't from the rust bucket states, here in the USA.

I have loaned out that tool probably more times than i personally have used it myself.

And a few times i got it back with the **** being beat out of it, but that's what the tool is for if you got a stubborn torsion bar.

I made a couple of them out of mahogany wood. Left no marks but destroyed the first one on the second bar. So made another. I just had the mahogany laying around scrap from a different project.

Easy enough to make.-A short piece of angle iron and a couple of u bolts. Drill through one flat for the u-bolts. Attach so the 90 degree is hanging down. Whack it with a hammer. I recommend wrapping the bar with tape first.

jos51700

Green Bearing thread connoisseur

Easy enough to make.-A short piece of angle iron and a couple of u bolts. Drill through one flat for the u-bolts. Attach so the 90 degree is hanging down. Whack it with a hammer. I recommend wrapping the bar with tape first.

This. A buddy made one years ago and loaned it to me. Works like a champ. Heat and all that stuff doesn't apply (if you're going to heat a torsion bar, just cut it out. Heat ruins temper), but I do make it a point to try to twist the bar opposite the direction of rotation before I commence to hammertime. They rest on the points of the hex and sometimes the points can brinell and make little divots in the receiver.

Remember: God invented 5 pound sledges for a reason.

That's the same type I have. First thing I did was replace the bolts with aircraft grade 10 and it's never failed me.Mancini racing removal tool... lots of penetrating oil and diligence

I went through three sets of bolts but won the war

-