nm9stheham

Well-Known Member

This is just some 'FWIW' info that might be of mild interest to this pretty smart/active group of gearheads. I've read that different strokes and rod lengths change the angles at which peak displacement occur, etc., and that might be a factor in cam profiles, lobe angles, etc. So some spreadsheet work was used to compute piston speeds and displacement versus crank angle (both actual displacement and % of total displacement) for 3 different engines:

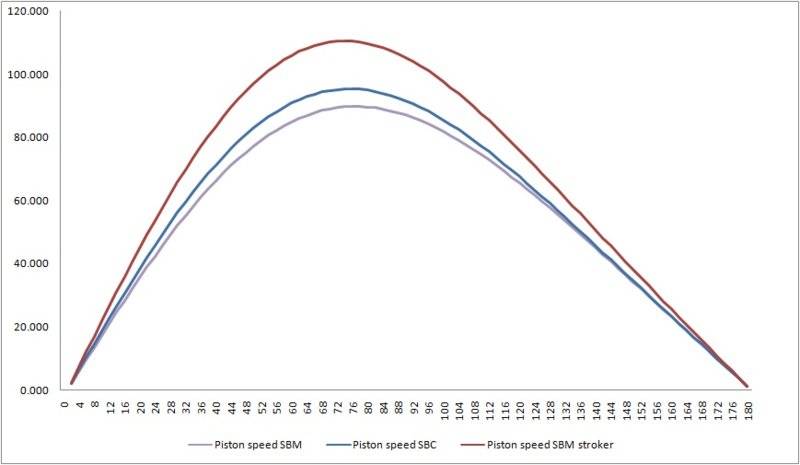

This 1st is graph is for actual piston speeds on the intake stroke, in feet per second at 6000 RPM:

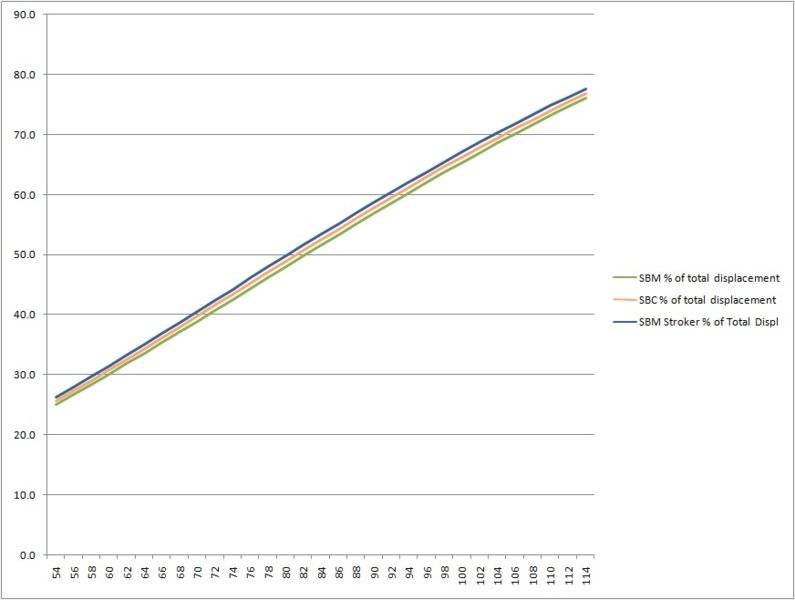

The 2nd graph is % of displacement versus crank angle; the data is expanded around the 50% level for clarity:

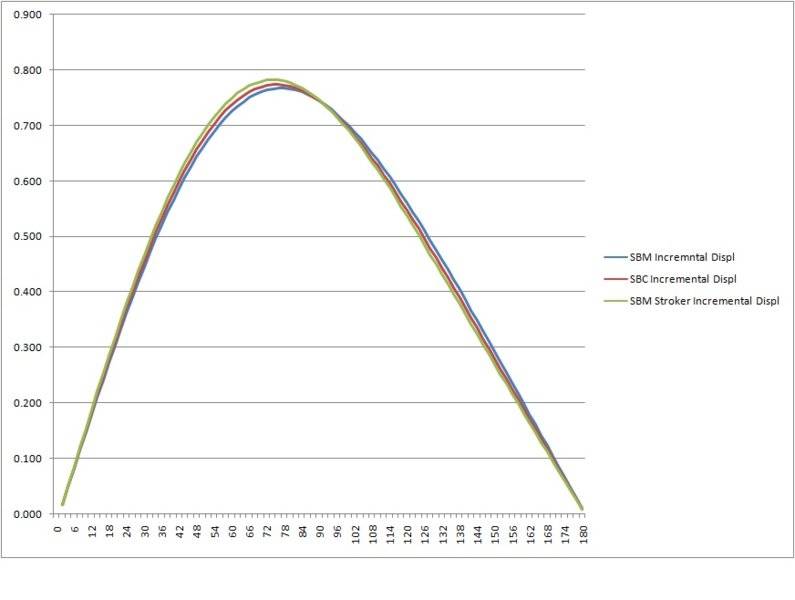

This 3rd graph is actual displacement rate, in c.i. versus every 2 degrees of crank angle. This is with all 3 engine equalized to 340 ci by adjusting bore, to make the difference in the angle of the peak displacement rate to be easier to see. (The 'per 2 degrees of crank angle' is just the way it was computed. If you want to know it per 1 degree of crank angle, just divide the vertical axis numbers by 2.)

Initial impressions: IMHO.... the last 2 graphs show that there is not a lot of difference in the angles at which peak displacement occurs. There is only about a 2+ degree spread in the displacements vs. the crank angles across these 3 stroke & rod combinations. So it seems that, for the range of common small block V8 designs from the 50's to 80's, there would not much changing in the cam lobe angles. You might want to use a 2 degree wider LSA for a 4" stroker SBM, or so it seems. But, hey, there could be more to this than I realize.....

Edit to add: Ooops... I reversed the intake and exhaust strokes in my brain! The effect would seem to be to NARROW the LSA with the 4" stroker, not widen it. The peak displacement rate on the exhaust would occur a bit later and the peak rate on the intake occurs a bit earlier.

- 340 SBM

- 350 SBC

- A 273 SBM stroked 4" to 333 ci (which is why this all started....)

This 1st is graph is for actual piston speeds on the intake stroke, in feet per second at 6000 RPM:

- Grey line is a standard 340 SBM rod and stroke: 3.31” stroke and 6.123” rod.

- Blue Line s a standard 350 Chevy SBC: 3.48” stoke and 5.7” rod.

- Red line is stroked out to 4.000” with a 5.95” rod length. (273 stroked out to approximately 333 ci.)

The 2nd graph is % of displacement versus crank angle; the data is expanded around the 50% level for clarity:

- Light green line is a standard 340 SBM rod and stroke: 3.31” stroke and 6.123”

- Orange line is a standard 350 Chevy SBC: 3.48” stoke and 5.7”

- Blue line is SBM stroked out to 4.000” with a 5.95” rod length. (273 stroked out to approximately 333 ci.) Note that this line closely represents any 4" stroked SBM, even with a 6.123" rod length.

This 3rd graph is actual displacement rate, in c.i. versus every 2 degrees of crank angle. This is with all 3 engine equalized to 340 ci by adjusting bore, to make the difference in the angle of the peak displacement rate to be easier to see. (The 'per 2 degrees of crank angle' is just the way it was computed. If you want to know it per 1 degree of crank angle, just divide the vertical axis numbers by 2.)

- Light blue line is a standard 340 SBM rod and stroke: 3.31” stroke and 6.123”; bore = 4.04"

- Red line is a standard 350 Chevy SBC: 3.48” stoke and 5.7”; bore = 3.94"

- Light green line is SBM stroked out to 4.000” with a 5.95” rod length; bore = 3.675". A 340 or 360 stroker graph will have the same shape and peak angle, but the peak will be about 20% higher.

Initial impressions: IMHO.... the last 2 graphs show that there is not a lot of difference in the angles at which peak displacement occurs. There is only about a 2+ degree spread in the displacements vs. the crank angles across these 3 stroke & rod combinations. So it seems that, for the range of common small block V8 designs from the 50's to 80's, there would not much changing in the cam lobe angles. You might want to use a 2 degree wider LSA for a 4" stroker SBM, or so it seems. But, hey, there could be more to this than I realize.....

Edit to add: Ooops... I reversed the intake and exhaust strokes in my brain! The effect would seem to be to NARROW the LSA with the 4" stroker, not widen it. The peak displacement rate on the exhaust would occur a bit later and the peak rate on the intake occurs a bit earlier.

Last edited: