Somehow this turned into my engine build thread - so here is the update...

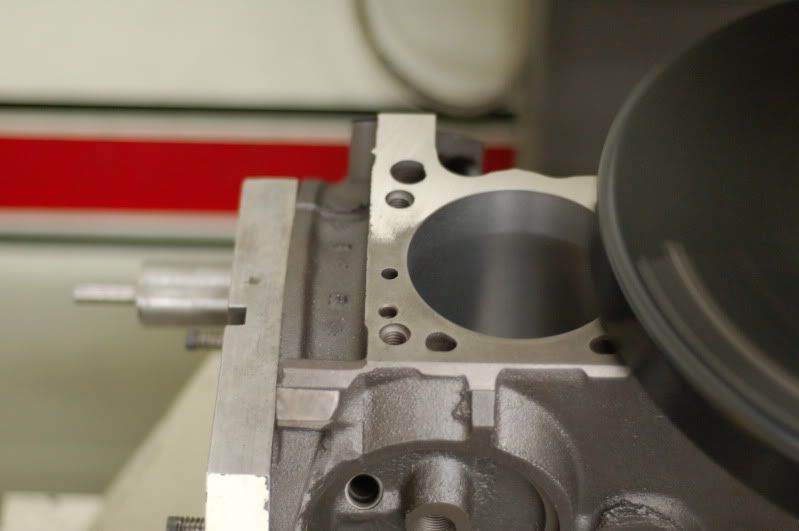

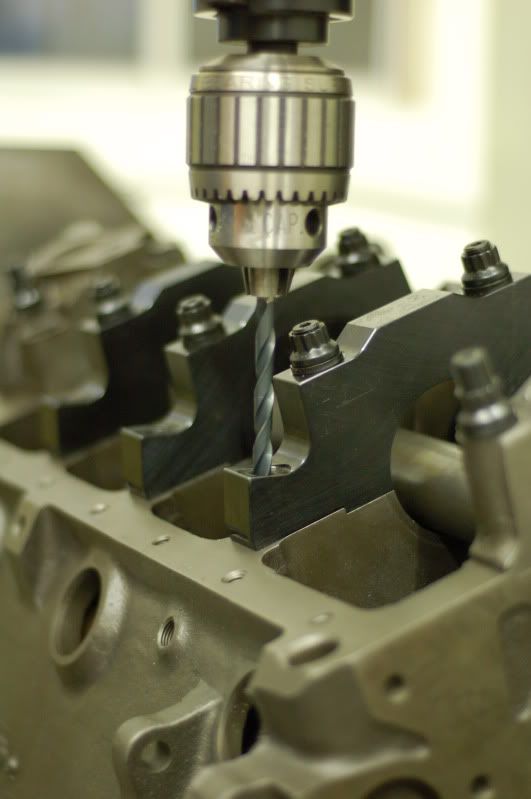

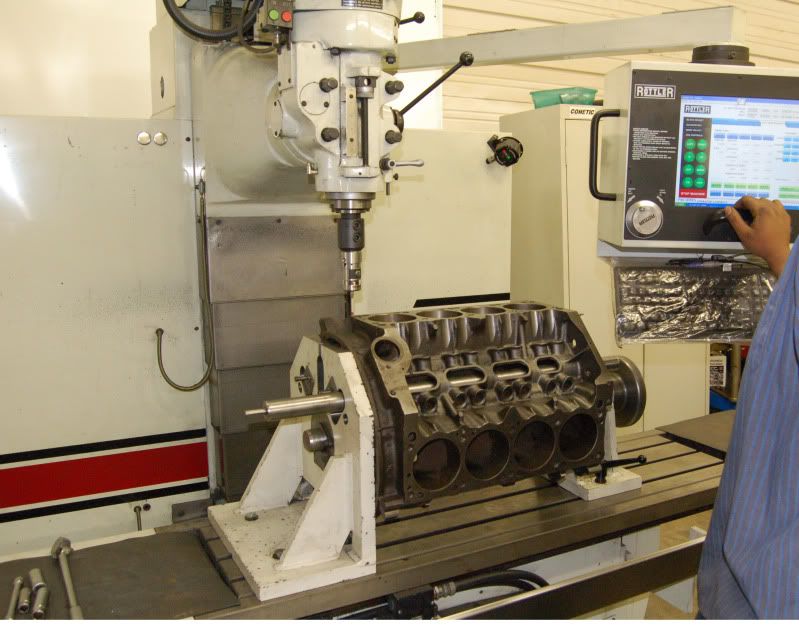

well just a quick update- the deck was a mess when we put it on the ROTTLER CNC machine - 12 thousands off on the drivers side and 10 thousands off on the passenger side.

While the deck was flat - and this block was machined at a very reputable shop in the 80's the machinery of today has brought inconsistencies like this to the forefront of modern engine building.

so I had a flat, crooked deck on this sucker. But it will clean up within spec for the rotating assembly.

Speaking about the rotating assembly - It measured out to 1794.6 grams for the bobweight - nice and light!

Weights were consistent for everything :

Rods: +/- 2 grams - 599-601

pistons - +/- 1 gram - 471-472

Just out of curiosity - does anyone know the stock 340 rotating assembly bobweight?

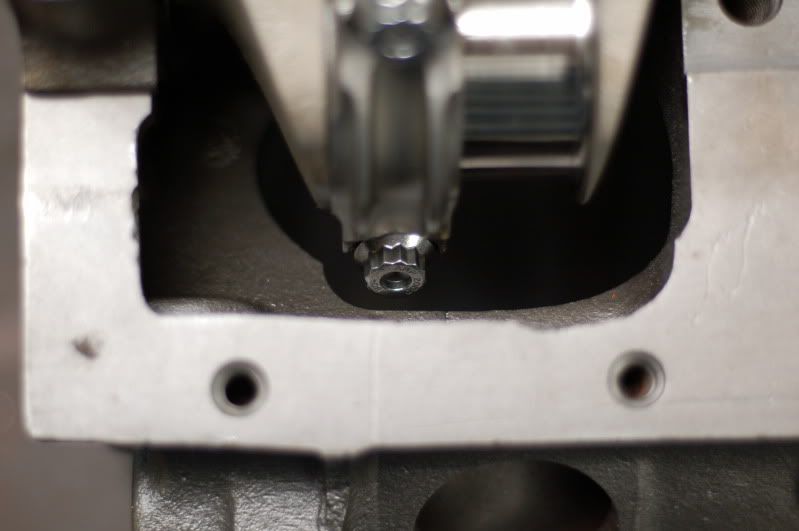

The TCI Rattler had to be fitted to the crank which was 1.532" and the balancer was 2 1/2 thousands smaller - It was honed to fit with a 1 1/2 thou press fit.

so we're gettin there - slowly but surely.

I sent a reply to your pm and said your box is full.