You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Realest's 1969 Dart Custom

- Thread starter Realest

- Start date

-

While you have it on the rotisserie would be a good time to install subframe connectors, instead of trying to weld overhead.

Dartsun

Mopar Dude

I agree after welding some on my garage floor this last summer. I’m getting a rotisserie for my next mopar project.While you have it on the rotisserie would be a good time to install subframe connectors, instead of trying to weld overhead.

Yup! that is the plan. I can't weld worth a darn over head and out of position.While you have it on the rotisserie would be a good time to install subframe connectors, instead of trying to weld overhead.

Pretty cool build. Boy a rotisserie sure makes life easier.Today I worked an finalizing mocking up the USCT spring relocate brackets. I hope to find time to weld in this week.

View attachment 1716212691

View attachment 1716212692

View attachment 1716212693

View attachment 1716212695

View attachment 1716212696

Thank you! Yes, I would recommend a rotisserie to anyone.Pretty cool build. Boy a rotisserie sure makes life easier.

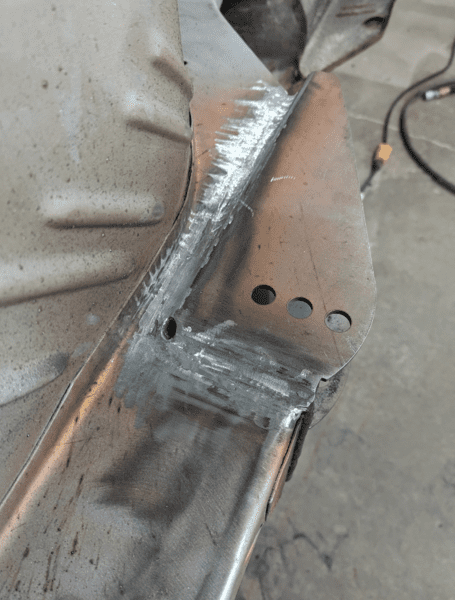

I've been making some progress welding and grinding the spring relocate brackets in emphasis on the grinding part.

This weekend my dad and I made a trip across the boarder to pick up my shipment from AMD.

This weekend my dad and I made a trip across the boarder to pick up my shipment from AMD.

Isn't that fun welding .040 sheet metal to 3/16 plate ? Lol, I had a bunch of fun with mine.I've been making some progress welding and grinding the spring relocate brackets in emphasis on the grinding part.

View attachment 1716219879

This weekend my dad and I made a trip across the boarder to pick up my shipment from AMD.

View attachment 1716219882

I am probably doing it for more selfish reason LOL, but you're welcome.Thanks for outstanding photos of your project.

It will be a big help for us builders.

Red's '72 Dart

Well-Known Member

Very nice build so far! Keep up the good work!

Liking what you're doing!

I managed to get the sub frame connectors fully welded in, and started clean up on the penetration on the inside of the floor pan. I uncovered a thin area that I tried to initially weld up, but that wasn't an option. The area was too thin (+ my armature skills) causing the hole to get bigger. I eventually resorted to my first sheet metal patch which turned out okay. I still have a lot to learn when working with thin old metal. I have some holes to deal with, near the patch I installed, where the seat mount bracket is. That'll be a fun next adventure for me.

-