Facts.--- 69 Valiant 100 6 cyl auto. 9 in manual drums all around.--- What we did--- New drums all--- new wheel cyl. all--- new pads all--- all new clips, springs, all hardware to hold the brakes together.--- new front rubber brake lines--- New master cyl.--- only things not replaced All brake lines--- rubber brake line piece by rear axel--- and the distribution valve--- All 4 corners bled out.--- I have the exact same hard to stop brake system that I had before I replaced everything. PLUS hold on I took it to a shop to make sure it got done RIGHT. $900.oo dollars labor and no brakes. There scratching there heads trying to figure it out and are willing to help. If we only knew what to do. And I still have to rebuild the front end. Gotta have brakes first.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brakes won't stop my Valiant 100

- Thread starter Wolfgange

- Start date

-

junkyardhero

Well-Known Member

explain, in detail, "hard to stop". leave nothing out.

has anything been changed or modified: manual to power brakes, pedal, etx.

is the master cylinder correct for the application.

you're this far in, i'd replace the soft hoses and the distro blocks. if it's 69 you should the one with a prop valve/metering block/safety switch in it. that will at least eliminate another set of possible culprits.

has anything been changed or modified: manual to power brakes, pedal, etx.

is the master cylinder correct for the application.

you're this far in, i'd replace the soft hoses and the distro blocks. if it's 69 you should the one with a prop valve/metering block/safety switch in it. that will at least eliminate another set of possible culprits.

Everything on the car is Bone stock. When the brakes are applied There's no sensation or feel to the pedal. It just try's to stop. It's the correct master with 1 in bore. When you step on your brakes to stop you have a feel to the pedal. You can feel should I push harder or ease up a bit. It's like the buzzzzed girl you picked up at closing time. Your home your in but there's nothing , it just don't feel right. OK your coming up on traffic that's stopped. You know how much pressure you need to apply as you get close so you don't run into the stopped cars. You can feel your brakes being applied. There's no feel in the pedal so you just push . Not 100% sure what the wire on top of the distribution valve ( I think you call the Metering block/safety switch) doe's. The front two rubber hoses are new. I'm going to replace the one over the rear axel. Hope my explanation helps you help me Thanks for responding

Have you ever had a car with manual brakes? It is manual brakes right?

Do you have a factory service manual?

Did the shop bench bleed the master cyl.

Are the shoes on correctly?

Did they adjust the shoes out properly?

Do you have a factory service manual?

Did the shop bench bleed the master cyl.

Are the shoes on correctly?

Did they adjust the shoes out properly?

Vixen has 9" drums all around and she stops like a big dawg. I remember when the FOrd Taurus first came out, when we did brakes in the aftermarket with new rotors, we had to turn the new rotors and buff them with a Roloc buffer or they would just keep rolling, regardless of how hard you mashed the pedal. I wonder if those drums need that done?

My son has a '68 Fury that we replaced much of what you did & bled the brakes. Same issue as you had, poor braking. We replaced the rear rubber line and that fixed the problem. The inner rubber line had disintegrated and when pressure was applied the rubber "flapped" around and blocked the flow.-- only things not replaced All brake lines--- rubber brake line piece by rear axel---

Couple things. Short shoe on the front on all wheels. Pull master and measure bore. Im thinking its not 1”. Unless you actually measured it yourself i wouldnt trust what came in the box. Happened when we replaced master on buddy’s truck. Not the first time i have seen it.

Kinda what RRR was hinting at.

Poor brake linings or hard spots in the drum faces also will not stop worth a damn.

This kinda of issue is difficult to diagnose because it takes years of experience and seat of the pants knowledge that cannot be gifted over or thru a keyboard.

Poor brake linings or hard spots in the drum faces also will not stop worth a damn.

This kinda of issue is difficult to diagnose because it takes years of experience and seat of the pants knowledge that cannot be gifted over or thru a keyboard.

Who's master cylinder? A lot of crap out there....

1WildRT

Well-Known Member

Buy this...

Once you know how much hydraulic pressure is being generated it will tell you where to look for a problem....

Once you know how much hydraulic pressure is being generated it will tell you where to look for a problem....

Thanks thats next on my listMy son has a '68 Fury that we replaced much of what you did & bled the brakes. Same issue as you had, poor braking. We replaced the rear rubber line and that fixed the problem. The inner rubber line had disintegrated and when pressure was applied the rubber "flapped" around and blocked the flow.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 25,807

- Reaction score

- 13,113

I like your description;

If your brake-warning lamp is on, take a short-cut to the bottom

Drum brakes are "self-energizing" and as the car slows down, you can always feel the car slowing down ever more quickly, so you have to lift off the pedal as the car comes to a stop. That is what you are referring to, when you say "feel", and that is what your car is missing.

Plus, with working front brakes, the nose of the car will drop on brake application, and the tail will rise. If only the rear brakes re working, neither of those will happen. If only the front brakes are working, the rear will not rise properly, and the fronts may lock up for lack of weight transfer.

Because "feel" is blatantly missing, I'm gonna GUESS that your front brakes are not working right, if at all.

Because you didn't mention a pull, My GUESS is that neither side is working.

and so, my guess is that brake fluid is NOT moving from the M/C thru the Combination valve. Cuz it's pretty hard to believe that there is equally poor pressure from the valve to BOTH of the front W/Cs.

If your car does NOT have a brake booster; and you said manual;

The proof is to just jack the front wheels off the ground, apply the brakes, and attempt to turn the wheels. If they spin, then I'm right. But if they don't, we're not done yet. Take the wheel off and go get a 3-ft bar. Shove it between the studs and try again.

If the brakes work, and the bar won't rotate the wheel, I'm done, and IDK what the problem is.

But assuming I am right; we gotta start at the pedal.

Apply the brakes.

the first inch is just closing the Compensating port and pumping fluid out to the w/c's, first the rears, then the fronts, which then push the shoes out to the drums. Somewhere in the second inch, the shoes are ready to go to work, and hydraulic pressure begins to build. The pedal should be hard and high, some two inches from it's normal parking spot.

If it is not, then I guarantee that you have a problem, lol.

But if it is high and hard, that still does not mean it's right. The first 2-part question is this; Is the pushrod properly seated in the Power-piston, and retained in the socket? The second question hotly follows; is the compensating port open and properly synchronized to the power-piston?

If you can say yesyes, and yes, then we can move on. but

If you don't know for sure, go to Note-1 below.

So understanding how it's supposed to work, lets see how it goes wrong.

You say that the system was bled. Lets start here.

If the M/C was not properly bled; then air can still be in the "inter-chamber". That air cannot come out except thru the compensating port. And that requires the nose of the M/C to be pointed down, cuz the port is at the rear. But the fluid has to be agitated cuz it likes to stick to the metal. And so, agitation is by stroking the power-pistons, and having the fluid return into the reservoirs, thru short hoses you install, and/or thru the C-ports. This procedure is called "bench-bleeding". It must be continued until the air is all gone.

If this is not done then:

1) if the inter-chamber is not filled;

Then the rearmost piston will advance further than normal, until it physically pushes on the frontmost piston. This will then activate the rear brakes. However, The rearmost piston has travelled so far forward that in may not be able to activate the front brakes. The pedal will be very nearly on the floor before the rear brakes begin to work, assuming they have been properly adjusted.

2) if the inter-chamber is full but the the rear system has air in it, pretty much the same scenario will exist.

3) if only the front system has air in it, then the pedal will act normal, but the car will not slow down properly for two reasons; a) the front won't work at all, and b) the rear is only designed to , by the Proportioning valve, to provide some 15% of the stopping power.

By now it should be obvious that;

1) the pedal can talk to us by being high and hard.

2) rear brakes by themselves, are sheit.

3) the front brakes can be 100% perfect, but if the M/C does not move fluid in the system, then they won't work.

Ok so, as it happens, some M/C's have a compensating port in the front-most reservoir, that gets connected to the Inter-chamber, if the rear piston pushes the front piston, ahead, far enough. Knowing this, you can introduce a fluid leak into the rear brake system such that you can full-stroke the Power pistons and expel that air. But; the M/C has to be running uphill from the back to the front, and not all M/C's have that port.

> Here's another thing you should know;

if there is air in either the front or the rear system, it is easily proved, in one or more of the following ways;

1) the pedal is spongy, not hard, and

2) it travels more than about 2 inches before anything happens, and

3) if you stroke it several times in rapid succession, the pedal comes up higher. but as soon as you release the pedal, wait a couple of seconds, then it resumes it's former status

4) if you, rapid-pump the pedal then hold the pedal down on the last stroke preventing fluid return, and then, take the reservoir lid off and release the pedal; You may get an underhood geyser, as the compressed-air relaxes and blasts the fluid home. This geyser can blow fluid all over the underside of the hood and a pita to clean up. Don't try this, without taking measures to capture the brake-fluid cuz it eats paint. I will not buy you a paint job. Of course, you can regulate the rate of return-flow by modulating the pedal, turning an instantaneous gusher into a longer-timed modest fountain, but the learning curve can be very expensive.

Having thus proved the presence of air in the system, you now have to go find it. But at least you are on the trail.

Note-1

If you had to install the pushrod into the M/C , and have installed the retaining ring, then poked the assembly thru the firewall to attach the rod to the pedal, then the answer to the first question is yesyes; and probably so is the second answer a yes. But we still gotta prove it.

>First a lesson on how it should work;

With the pedal parked at the top of it's stroke, it will have pulled the pushrod to it's rearmost position. This will then have also pulled the power piston to it's parked position, at it's rearmost travel. This the compensating ports inside the reservoirs will be open to the chambers below.

In this position the chambers are filled with fluid.

Now, the two power chambers are normally not physically connected. Instead, only the rear piston is attached to the brake pedal, and there is a hydraulic chamber between it and the frontmost piston, which I'll call the inter-chamber, cz I can't remember it's proper name, and so, the frontmost chamber will be actuated by that inter-chamber. In the Mopar scheme, the rearmost chamber activates the front brakes, and the frontmost chamber activates the rears. Normally the front brakes do not begin to work until the rear shoes are pressing on the drums. This action then begins building pressure by the pedal being further applied.

The rear brakes are now hydraulically coupled to the inter-chamber, which if it is properly charged with brake fluid, is now acting like a solid piston. This action, by continued pedal travel, now forces fluid out to the front brakes, thru the Combination valve/etcetera. Now the system is on-line, and continued pedal travel is gonna increase the line pressure, in order to stop the car. This all happens in those two inches of pedal-travel. At this time, the pedal should turn hard, because the drums are cold and well-able to resist the shoe-pressure...... so long as the hoses are doing their jobs. If the hoses are 50 years old, fat chance. All that pressure is gonna go into expanding the hoses.

Ok so that's how it is supposed to work.

Note-2

plumbing the Combination valve.

This valve may have a proportioning valve to the rear brake line, but in an all-drum car, it shouldn't have one unless the rear w/c's are very large. Normally, proportioning is handled by smaller w/c's on the rear, and more narrow shoes.

Moving on, the top half of the valve is just a distribution block for the front system. Fluid from the REARMOST M/C chamber, goes in at the top-end and then splits to the individual lines going to each front wheel. The Three-port end goes to the front brakes.

The fluid from the FRONTMOST chamber, is sent to the rear brakes, usually at the bottom-side of the valve, then out the bottom to the rear brakes.

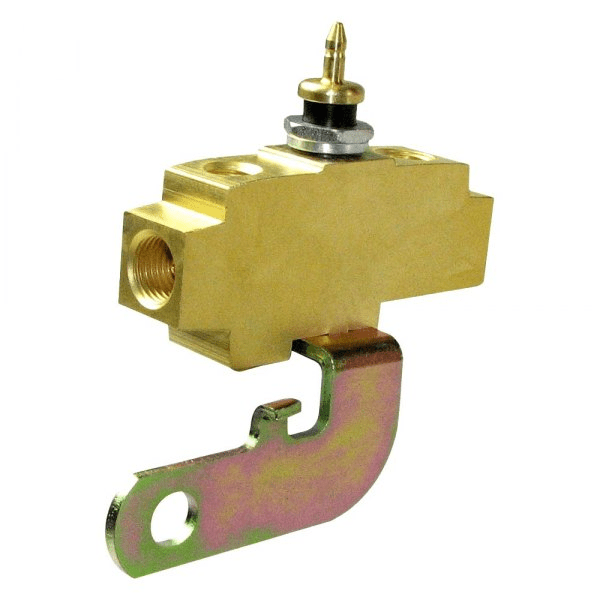

Here is a picture of a generic all-drum valve

Is your brake-warning lite on.

But, a 69 car should have a brake-warning lite on the dash, that is electrically connected to the safety switch portion of the Combination switch. This switch turns on that dashlite by grounding it if one or the other end of the cars loses brakes. Inside the body is a shuttle valve, that by moving sideways, grounds the switch, and turns on the light. If your dashlite is on, and it's not because the park brake is on, then the valve is off-center and one end of your car cannot work/it has been shut off. If the lite is off, prove it works!

So, if it is on, you gotta go figure out which end has been turned off.

On a mopar, that valve is supposed to be self-centering. So that when you fix the bad end, a couple of pedal strokes will turn it off. But, youknow, if the darn think is 53 years old, you don't know if the thing still works so you can't trust the light to tell you any more than something is wrong. And you cannot physically tell by looking at the valve.

The two ends are not connected except by the Pressure differential switch, which is sealed by wide, band-type, O-rings. Those rings, over time, get corrosion stuck to them, and they can swell up pretty hard and so, require a lot of hydraulic pressure to budge.

So how do you know when the valve is centered?

Easy, the dash-lite goes off..... if it works. Or;

you can check the switch for continuity from that bayonet-thing on the switch to the brass body, which, if the switch is properly centered, will be INFINITE.

Moving on, the top half of the valve is just a distribution block for the front system. Fluid from the REARMOST M/C chamber, goes in at the top-end and then splits to the individual lines going to each front wheel. The

The fluid from the FRONTMOST chamber, is sent to the rear brakes, usually at the bottom-side of the valve, then out the bottom to the rear brakes.

If your brake-warning lamp is on, take a short-cut to the bottom

Drum brakes are "self-energizing" and as the car slows down, you can always feel the car slowing down ever more quickly, so you have to lift off the pedal as the car comes to a stop. That is what you are referring to, when you say "feel", and that is what your car is missing.

Plus, with working front brakes, the nose of the car will drop on brake application, and the tail will rise. If only the rear brakes re working, neither of those will happen. If only the front brakes are working, the rear will not rise properly, and the fronts may lock up for lack of weight transfer.

Because "feel" is blatantly missing, I'm gonna GUESS that your front brakes are not working right, if at all.

Because you didn't mention a pull, My GUESS is that neither side is working.

and so, my guess is that brake fluid is NOT moving from the M/C thru the Combination valve. Cuz it's pretty hard to believe that there is equally poor pressure from the valve to BOTH of the front W/Cs.

If your car does NOT have a brake booster; and you said manual;

The proof is to just jack the front wheels off the ground, apply the brakes, and attempt to turn the wheels. If they spin, then I'm right. But if they don't, we're not done yet. Take the wheel off and go get a 3-ft bar. Shove it between the studs and try again.

If the brakes work, and the bar won't rotate the wheel, I'm done, and IDK what the problem is.

But assuming I am right; we gotta start at the pedal.

Apply the brakes.

the first inch is just closing the Compensating port and pumping fluid out to the w/c's, first the rears, then the fronts, which then push the shoes out to the drums. Somewhere in the second inch, the shoes are ready to go to work, and hydraulic pressure begins to build. The pedal should be hard and high, some two inches from it's normal parking spot.

If it is not, then I guarantee that you have a problem, lol.

But if it is high and hard, that still does not mean it's right. The first 2-part question is this; Is the pushrod properly seated in the Power-piston, and retained in the socket? The second question hotly follows; is the compensating port open and properly synchronized to the power-piston?

If you can say yesyes, and yes, then we can move on. but

If you don't know for sure, go to Note-1 below.

So understanding how it's supposed to work, lets see how it goes wrong.

You say that the system was bled. Lets start here.

If the M/C was not properly bled; then air can still be in the "inter-chamber". That air cannot come out except thru the compensating port. And that requires the nose of the M/C to be pointed down, cuz the port is at the rear. But the fluid has to be agitated cuz it likes to stick to the metal. And so, agitation is by stroking the power-pistons, and having the fluid return into the reservoirs, thru short hoses you install, and/or thru the C-ports. This procedure is called "bench-bleeding". It must be continued until the air is all gone.

If this is not done then:

1) if the inter-chamber is not filled;

Then the rearmost piston will advance further than normal, until it physically pushes on the frontmost piston. This will then activate the rear brakes. However, The rearmost piston has travelled so far forward that in may not be able to activate the front brakes. The pedal will be very nearly on the floor before the rear brakes begin to work, assuming they have been properly adjusted.

2) if the inter-chamber is full but the the rear system has air in it, pretty much the same scenario will exist.

3) if only the front system has air in it, then the pedal will act normal, but the car will not slow down properly for two reasons; a) the front won't work at all, and b) the rear is only designed to , by the Proportioning valve, to provide some 15% of the stopping power.

By now it should be obvious that;

1) the pedal can talk to us by being high and hard.

2) rear brakes by themselves, are sheit.

3) the front brakes can be 100% perfect, but if the M/C does not move fluid in the system, then they won't work.

Ok so, as it happens, some M/C's have a compensating port in the front-most reservoir, that gets connected to the Inter-chamber, if the rear piston pushes the front piston, ahead, far enough. Knowing this, you can introduce a fluid leak into the rear brake system such that you can full-stroke the Power pistons and expel that air. But; the M/C has to be running uphill from the back to the front, and not all M/C's have that port.

> Here's another thing you should know;

if there is air in either the front or the rear system, it is easily proved, in one or more of the following ways;

1) the pedal is spongy, not hard, and

2) it travels more than about 2 inches before anything happens, and

3) if you stroke it several times in rapid succession, the pedal comes up higher. but as soon as you release the pedal, wait a couple of seconds, then it resumes it's former status

4) if you, rapid-pump the pedal then hold the pedal down on the last stroke preventing fluid return, and then, take the reservoir lid off and release the pedal; You may get an underhood geyser, as the compressed-air relaxes and blasts the fluid home. This geyser can blow fluid all over the underside of the hood and a pita to clean up. Don't try this, without taking measures to capture the brake-fluid cuz it eats paint. I will not buy you a paint job. Of course, you can regulate the rate of return-flow by modulating the pedal, turning an instantaneous gusher into a longer-timed modest fountain, but the learning curve can be very expensive.

Having thus proved the presence of air in the system, you now have to go find it. But at least you are on the trail.

Note-1

If you had to install the pushrod into the M/C , and have installed the retaining ring, then poked the assembly thru the firewall to attach the rod to the pedal, then the answer to the first question is yesyes; and probably so is the second answer a yes. But we still gotta prove it.

>First a lesson on how it should work;

With the pedal parked at the top of it's stroke, it will have pulled the pushrod to it's rearmost position. This will then have also pulled the power piston to it's parked position, at it's rearmost travel. This the compensating ports inside the reservoirs will be open to the chambers below.

In this position the chambers are filled with fluid.

Now, the two power chambers are normally not physically connected. Instead, only the rear piston is attached to the brake pedal, and there is a hydraulic chamber between it and the frontmost piston, which I'll call the inter-chamber, cz I can't remember it's proper name, and so, the frontmost chamber will be actuated by that inter-chamber. In the Mopar scheme, the rearmost chamber activates the front brakes, and the frontmost chamber activates the rears. Normally the front brakes do not begin to work until the rear shoes are pressing on the drums. This action then begins building pressure by the pedal being further applied.

The rear brakes are now hydraulically coupled to the inter-chamber, which if it is properly charged with brake fluid, is now acting like a solid piston. This action, by continued pedal travel, now forces fluid out to the front brakes, thru the Combination valve/etcetera. Now the system is on-line, and continued pedal travel is gonna increase the line pressure, in order to stop the car. This all happens in those two inches of pedal-travel. At this time, the pedal should turn hard, because the drums are cold and well-able to resist the shoe-pressure...... so long as the hoses are doing their jobs. If the hoses are 50 years old, fat chance. All that pressure is gonna go into expanding the hoses.

Ok so that's how it is supposed to work.

Note-2

plumbing the Combination valve.

This valve may have a proportioning valve to the rear brake line, but in an all-drum car, it shouldn't have one unless the rear w/c's are very large. Normally, proportioning is handled by smaller w/c's on the rear, and more narrow shoes.

Moving on, the top half of the valve is just a distribution block for the front system. Fluid from the REARMOST M/C chamber, goes in at the top-end and then splits to the individual lines going to each front wheel. The Three-port end goes to the front brakes.

The fluid from the FRONTMOST chamber, is sent to the rear brakes, usually at the bottom-side of the valve, then out the bottom to the rear brakes.

Here is a picture of a generic all-drum valve

Is your brake-warning lite on.

But, a 69 car should have a brake-warning lite on the dash, that is electrically connected to the safety switch portion of the Combination switch. This switch turns on that dashlite by grounding it if one or the other end of the cars loses brakes. Inside the body is a shuttle valve, that by moving sideways, grounds the switch, and turns on the light. If your dashlite is on, and it's not because the park brake is on, then the valve is off-center and one end of your car cannot work/it has been shut off. If the lite is off, prove it works!

So, if it is on, you gotta go figure out which end has been turned off.

On a mopar, that valve is supposed to be self-centering. So that when you fix the bad end, a couple of pedal strokes will turn it off. But, youknow, if the darn think is 53 years old, you don't know if the thing still works so you can't trust the light to tell you any more than something is wrong. And you cannot physically tell by looking at the valve.

The two ends are not connected except by the Pressure differential switch, which is sealed by wide, band-type, O-rings. Those rings, over time, get corrosion stuck to them, and they can swell up pretty hard and so, require a lot of hydraulic pressure to budge.

So how do you know when the valve is centered?

Easy, the dash-lite goes off..... if it works. Or;

you can check the switch for continuity from that bayonet-thing on the switch to the brass body, which, if the switch is properly centered, will be INFINITE.

Moving on, the top half of the valve is just a distribution block for the front system. Fluid from the REARMOST M/C chamber, goes in at the top-end and then splits to the individual lines going to each front wheel. The

The fluid from the FRONTMOST chamber, is sent to the rear brakes, usually at the bottom-side of the valve, then out the bottom to the rear brakes.

Last edited:

I use one finger a lot myself. lolI just lost a couple responses to my dilemma Sorry I'm 75 never owned a cell phone. Don't have a debit card. Use one finger on this %)#& computer . And having trouble using this forum.

Newbomb Turk

Well-Known Member

We used Viper brakes on this Valiant. Runs 160 mph on the front straight at Portland International and the Viper brakes haul it down just fine before the festival curves.

View attachment 1716235327

What a beautiful car. I love that thing.

oldmopardude

Well-Known Member

My advice is focused on you having a hard pedal but ineffective stopping power,,,,if that isn't the case then Ignore me. But,,,The nine inch brakes just don't don't work well with any wheels larger than the original 13 inch rim. i know, as I have a 71 demon slant six that would stop only very poorly, with 14x5.5 Rallye wheels and 205/70x14 tires. (the brakes were all newly rebuilt or new NOS as well)

So, I went back to some 14 inch 4.5 with 195/75 x14 and the braking improved greatly. but, once the original 13 inch x 4.5 rims and 185/75x13 tires went on it stops on a dime, just like back in the day (1970)when I also had a 68 valiant coupe . If I convert the car to a 340, all that will go away asap!!!

it is all about weight and mass, as the larger and heavier the wheel, the more brakes you need to stop. that is why the 68/69 V8 darts/Valiants had 10 inch brakes with 14x4.5 inch rims..V8 A/C cars got 14x5.5 rims with D70-14 tires, with 340 Torsion bars and 10 inch brakes as standard equipment.

The demon looked great with the rallye wheels, but it had a super hard pedal and poor stopping power. the car now is sadly back to stock rims and hubcaps.

But it stops perfectly.

So, I went back to some 14 inch 4.5 with 195/75 x14 and the braking improved greatly. but, once the original 13 inch x 4.5 rims and 185/75x13 tires went on it stops on a dime, just like back in the day (1970)when I also had a 68 valiant coupe . If I convert the car to a 340, all that will go away asap!!!

it is all about weight and mass, as the larger and heavier the wheel, the more brakes you need to stop. that is why the 68/69 V8 darts/Valiants had 10 inch brakes with 14x4.5 inch rims..V8 A/C cars got 14x5.5 rims with D70-14 tires, with 340 Torsion bars and 10 inch brakes as standard equipment.

The demon looked great with the rallye wheels, but it had a super hard pedal and poor stopping power. the car now is sadly back to stock rims and hubcaps.

But it stops perfectly.

Last edited:

-