You can use this method, it works well. Just remember to set them at zero lash initially, then adjust for actual use after break-in.

Valve adjustment for LA headed engine:

If your engine is assembled already you need to remove all the pushrods (if they are in) and both sets of rockers (obviously) and the spark plugs should be removed.

If you only have one adjustable push-rod length checker, do the intake and then the exhaust (or exhaust then intake, does not matter).

Make sure the cam is on the base circle on the cylinder you are checking and put the adjustable pushrod(s) in place (adjusted shorter than needed) and install your rockers. You only need two on at this time, but you can leave them all on, no matter. Adjust the adjuster screws so they show about 2-3 threads protruding out the bottom of the rocker and lock them in place. If the thread count that the rocker manufacturer suggests is different than what I suggested, go with theirs.

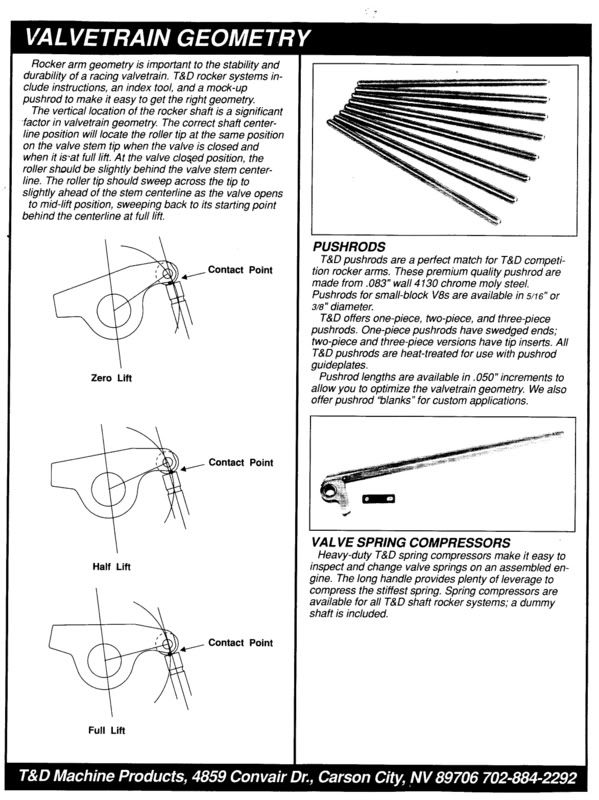

The first thing to look at is the roller tip to valve alignment. The tip should be just inboard of center on the valve at zero lift.( see Valvetrain Geometry sheet below)

If that looks good, you can move on to adjusting the pushrod(s).

Adjust the pushrod(s) to take out all lash. Do not preload the lifter(s).

Have a helper slowly rotate the engine by hand 2 full revs and watch the roller(s) on the valve(s) closely. It should start at just slightly IB of center on the base circle of the cam, roll out to just OB of center at half lift, and end up at just IB of center at full lift.

If this all works out, add .040" to the actual pushrod length. This is the correct length.

If your roller tip is not in the right spot, you either have to shim the rocker shafts up or possibly use lash caps on the valves to get the required geometry. I have never used the lash caps so maybe some of the guys that have could tell you about those, if you require them.

Final adjustment procedure after new pushrod install:

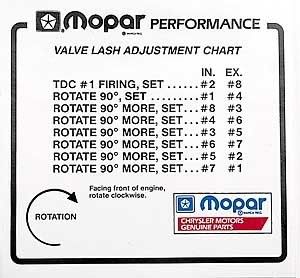

When the intake just starts to open, adjust the exhaust

When the exhaust closes, adjust the intake

also, a quicker method:

This sheet really helps, too:

The same procedure with some hardware changes applies to all pushrod engines. I hope all this info is not overwhelming, but it is important to the life of your engine.

ZDDP is what your cam needs to survive. This can be found at your local auto parts store, Walmart, etc in a little blue bottle...STP Oil Treatment. The store brand is also fine. I use it as an assembly lube and I use it in my old engines on oil changes. Modern engines have roller valvetrains and don't need it as much. Also, modern engines require lighter weight oils because the tolerances are generally tighter. The ZDDP additive will increase and maintain a higher viscosity over the life of the oil.

Most motor oils contain some ZDDP, but in much lower levels than they used to, before cat convertors. ZDDP is not good for convertors so it has been regulated out of motor oil. Generally, most motor oils will contain 400 - 800 PPM of ZDDP. Adding STP will raise that number up to at least three times that. :cheers: