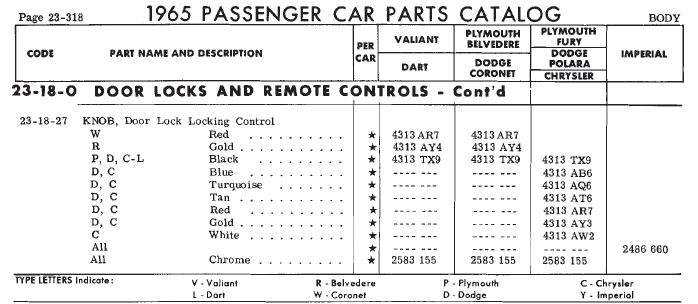

Take another look now I've expanded the view of the FPC page. The vertical list of models is spurious; it might just as well read "All" (once) -- if you follow that vertical list across, you would then have to think that all Coronets came with red lock knobs, all Belvederes came with gold lock knobs, all Plymouths and Dodges as well as low-line Chryslers came with black lock knobs, etc. In this particular corner of the FPC, we have to look primarily at the column headings to see which car lines had what colour selection of lock knobs.

I have seen enough unrestored yellow A-bodies with enough gold and enough black lock knobs to stick to my guns on that one. I installed chrome lock knobs on several of my own vehicles over the years because at the time I thought they looked keen, and they were readily available right on the parts store shelf. I'd happily update my knowledge, but for that to happen somebody (or preferably several somebodies) will have to step forward and say "my '65 Dart GT had chrome lock knobs the day we picked it up new from the dealership".

Dan!

I vent out to the barn where I have all the doors etc.

Picture #1 shows my newly accuired 1965 Dart 270 2 dr sedan. One owner, assembled in early June of 65 in Detroit. Black door knobs.

Picture #2 shows 65 Valiant V100 three owner car with light red door knobs.

Picture #3 shows right rear door from a 1965 Dart 270 wagon sold in Portland and assembled in Los Angeles in early 1965. One owner car.

Picture #4 shows black door knobs on a black 1965 Dart 270 V8 one owner car assembled in Detroit.

Picture #5 shows my original right side door with factory chromed door knobs. Assembled in Los Angeles on January 27th 1965.

Picture #6 shows black door knobs on my one owner 270 V8 wagon assembled in Los Angeles.

Picture #7 shows the turquise door knobs from my Dart 270 assembled in early August 1964 in Detroit.

For sure I know that all Dart GTs, Barracudas and Valiant Signets sold new here in Sweden had the chromed door knobs. All those care were assembled in Detroit.

All 1965 Dart GTs what I know of came equipped with chromed door knobs. BUT, I have no documentation to back it up! And yes Dan, there must be some kind of documentation of this but during my 35 years into 65 Darts I haven't seen anything about it! But somewhere.........

Some FABO members must have a picture of the door knobs of their one owner Dart GT, Valiant Signet or Barracuda!