Hemiorangeswinger

Dodge Material

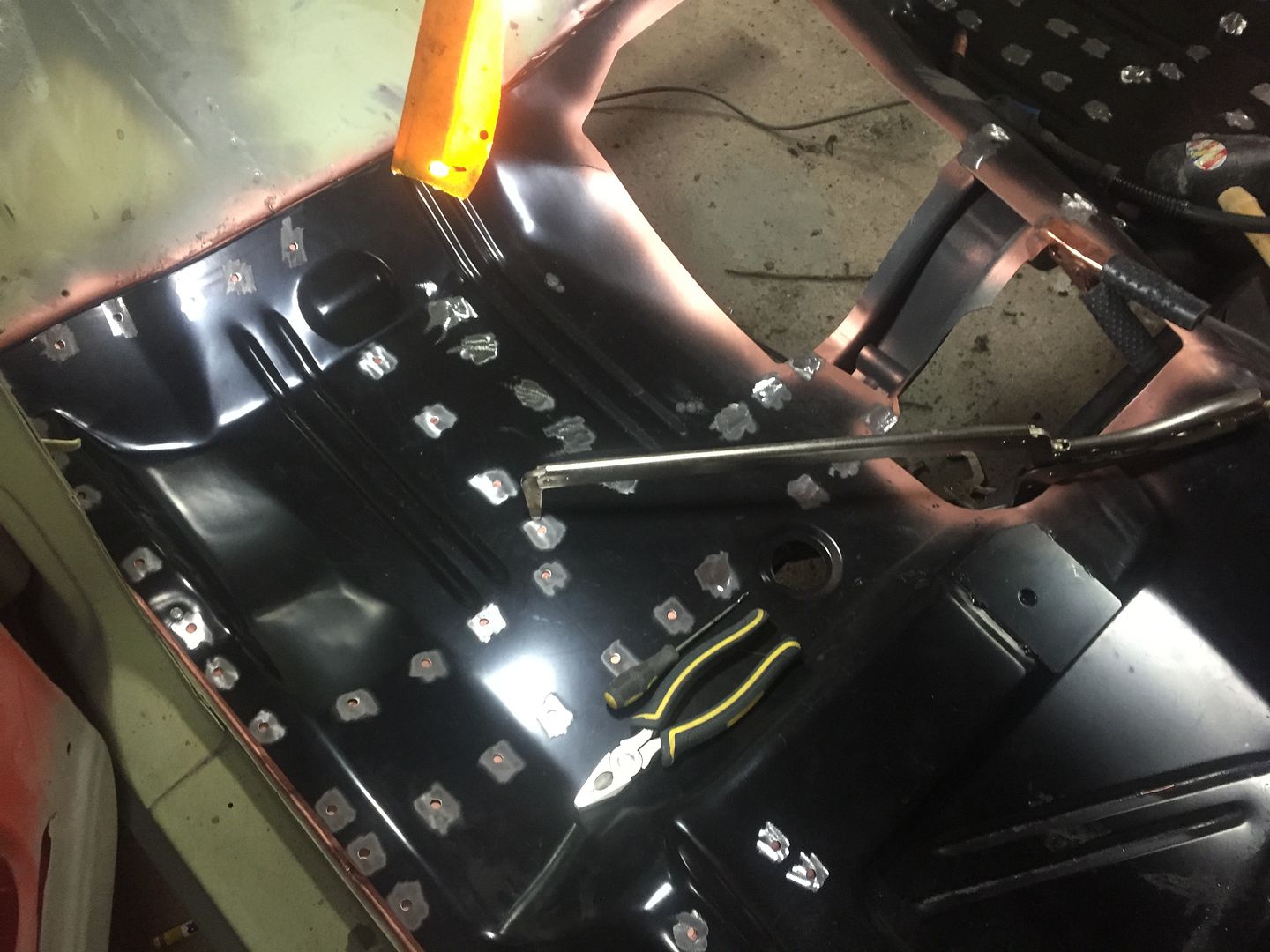

I went with the full quarters and outer wheel wells Randy and needed the trunk floor drops, also needed a new gas tank mine has a number of big dents in it. Also got the wheel well mouldings, I didn't know who's mouldings I should try so might as well try AMD's. Unfortunately I wouldn't have needed any of the sheet metal except for an early 80's teenage self inflicted wound in the form of some flaring of my quarters for some bigger tires, hey it was a different time, dumb ***!!!

Sounds like a pretty solid car! Haha my car had the wheel well lips cut off in the back and someone siliconed the quarters to the inner wheel well tubs to prevent them from flapping in the wind, and the rest of the car was sculpted with chicken wire and filler.. Quarters, rockers, fenders and doors. I bet they spent weeks building the car from filler!

I have that socket if you want to borrow it I can send it to you.

Jim

Thanks for the offer Jim! I will PM you if I have troubles getting them on with my crescent wrench.

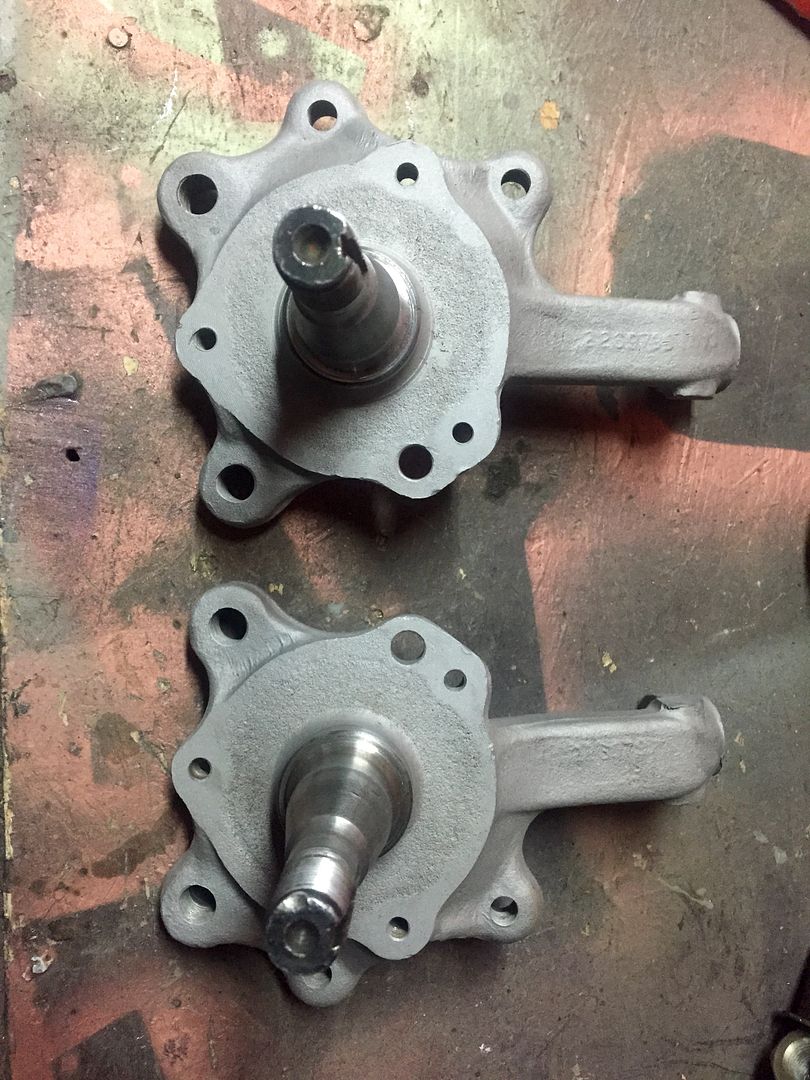

I got the spindles blasted and the bolt hardware soaking in evaporust. I will take a tap and die and clean all the threads too.