kingcrunch

Well-Known Member

Howdy,

i guess this is my first own thread here.

Welcome to the mess i got myself into.

This is "Mr. Curtis", my 1985 D150 (slant six, a833, 8.25 3:55).

Rust free (literately) Texas truck, ran good, some maintenance required. I want more.

I want a race truck for autocross, track days, hill climbs and general bombing around on the Autobahn (i am located in Germany).

So in addition to Mr. Curtis i bought this little accelerator:

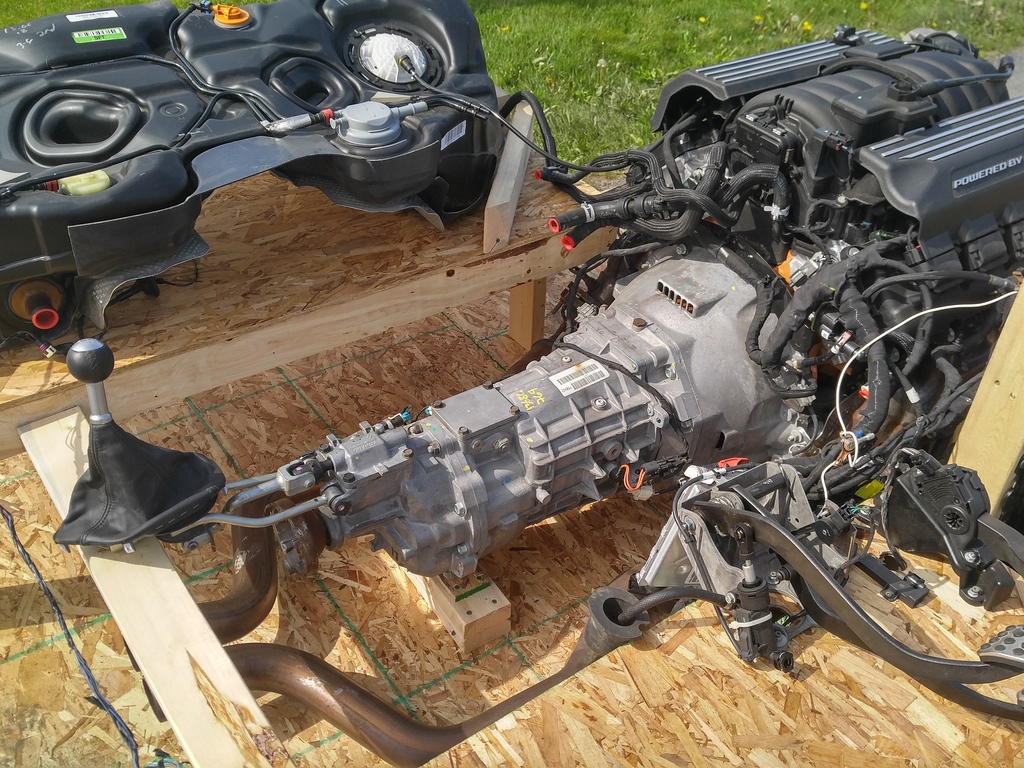

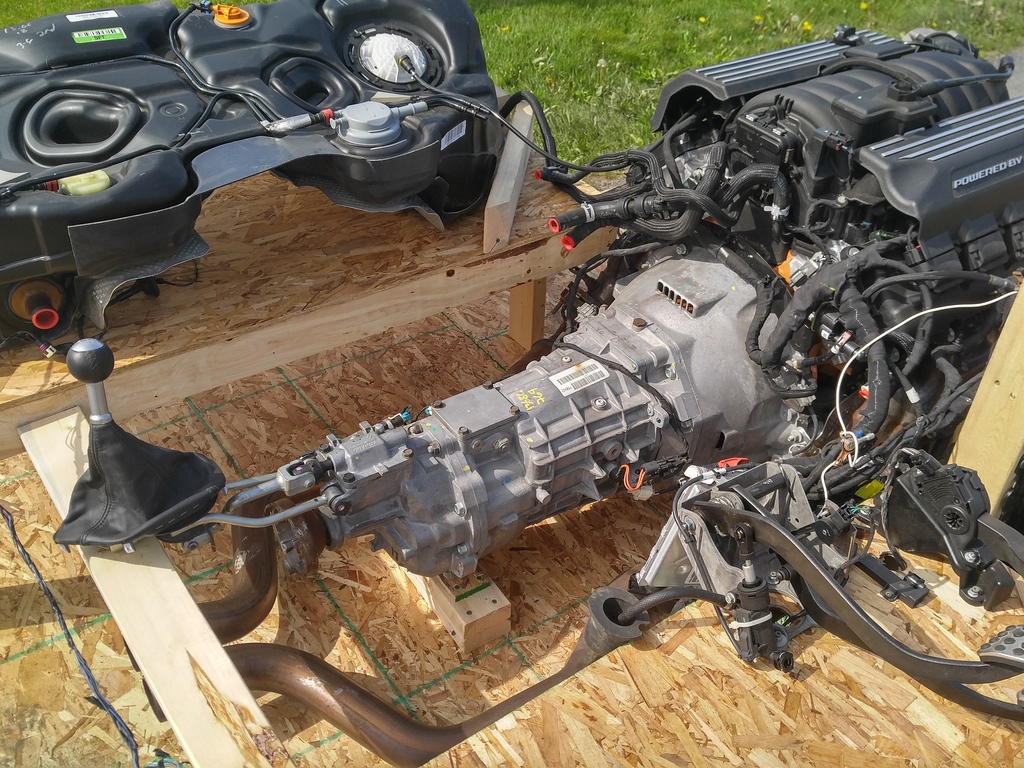

A poor 2015 Challenger SRT-8 donated its 485hp drivetrain (engine, transmission, wiring harness, ECUs, fuel tank, ABS module, tachometer, pedal box, exhaust, etc.) in form of a turn-key pallet from Cleveland Power and Performance (Cleveland Power & Performance - Late-Model Car Parts, Restomod, Salvage Rebuilds, Custom Cars).

They take a short video of every turn-key-pallet they sell.

Good thing Dodge made a "race truck" from 04 to 06.

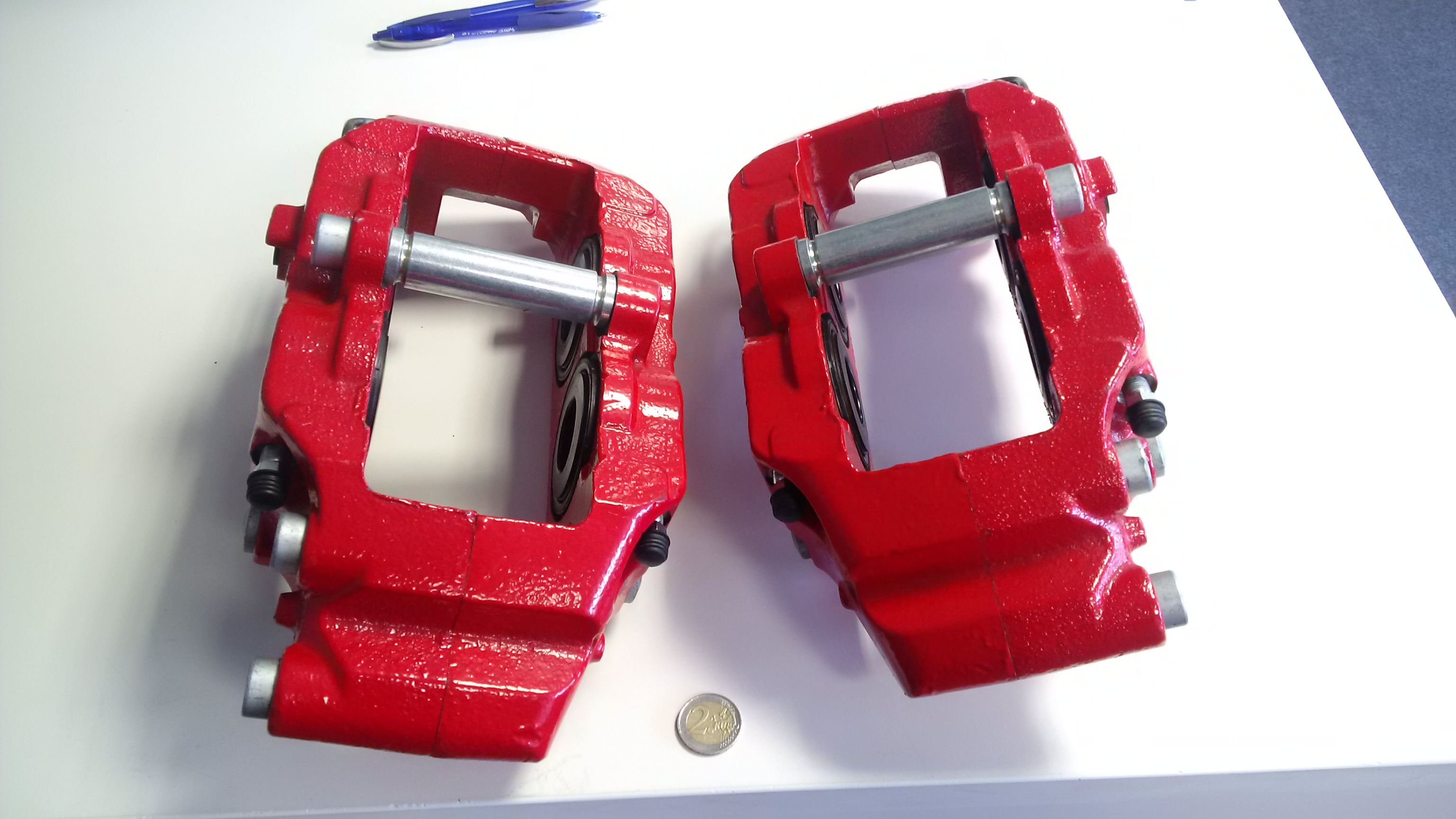

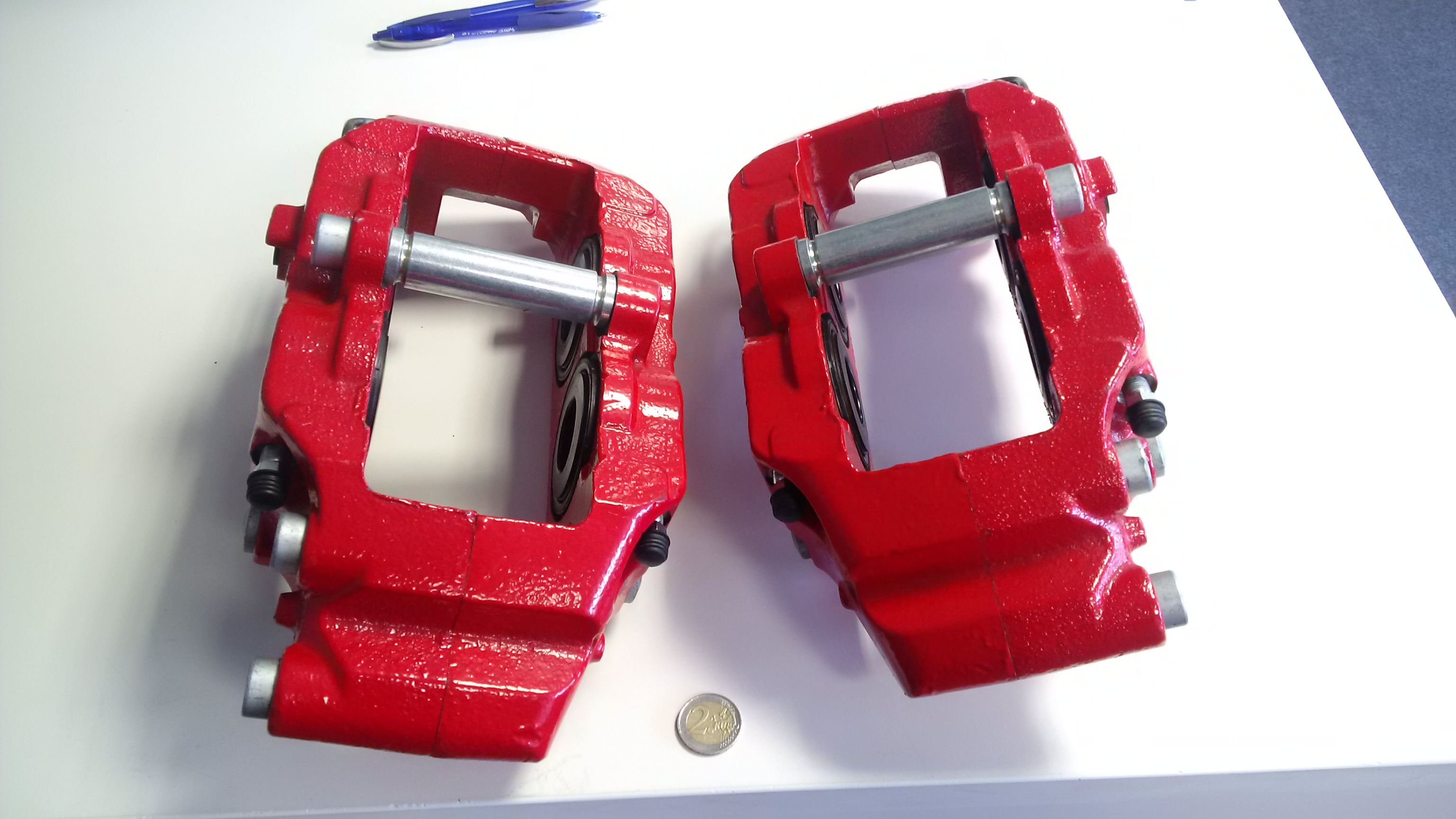

A Ram SRT 10 donates its Dana 60 HD rear axle (14" rotors with large two piston calipers) and parts of its front suspension (15" rotors with monstrous four piston caliper).

A D150 is about 3750 lbs, the 500bhp SRT-10 weighs about 5130 lbs.

It should be a fun truck with the Challengers 392 but i guesstimate it runs out of steam at around 150mph.

Any regular six cylinder Diesel station wagon does that in Germany.

I want more.

I want to brute force it to 170. But that's step two.

For step one this is the game plan:

- install Chevy C10 trailing arms (reinforced like on C20s) with coil springs.

I am in the process of making CAD drawings for the custom crossmembers.

It will be installed with a custom panhard bar, relocated shock mounts and a small sway bar

- fab and install frame-stiffening crossmembers, maybe tubular cross-bracing

- fab and install parts to adapt 05/06 Ram SRT-10 lower control arms, spindles and upper control arms and the rack and pinion steering.

- drop in the 6.4 with a Cherokee SRT-8 oil pan and make it work.

- have a specialized builder make a race-suitable cage (that will also stiffen up the chassis with rear and front outriggers

Also proper race seats, harnesses (regular street legal 3-point aswell) will be installed.

- carbon fiber bumper (moulding of the original part), carbon fiber hood (or at least air ducts for venting the engine compartment), etc.

I figure getting the 6.4 to work in my D150 is the most complicated part of this operation.

Everything else is precise measuring, fabbing parts and a bit of brainstorming through parts catalogues and Ebay.com

The 6.4 comes with an ABS-module for example. I can not re-use that with my truck, the calibration will not match the chassis behaviour OR the brake system so i need to get rid of that without disturbing the network of ECUs.

I wonder if there is a way to do that with say WiTech hardware and software.

Does anyone have experience with that?

One problem is:

I need to keep the original ECUs to make this thing road legal concerning emissions.

So there's no way of putting a Megasquirt Pro in the truck and running it that way.

This project would be a lot less fun if i could not make it road legal, so consider this a must-criteria.

So here it is... The Mr. Curtis project. Hope you like it.

i guess this is my first own thread here.

Welcome to the mess i got myself into.

This is "Mr. Curtis", my 1985 D150 (slant six, a833, 8.25 3:55).

Rust free (literately) Texas truck, ran good, some maintenance required. I want more.

I want a race truck for autocross, track days, hill climbs and general bombing around on the Autobahn (i am located in Germany).

So in addition to Mr. Curtis i bought this little accelerator:

A poor 2015 Challenger SRT-8 donated its 485hp drivetrain (engine, transmission, wiring harness, ECUs, fuel tank, ABS module, tachometer, pedal box, exhaust, etc.) in form of a turn-key pallet from Cleveland Power and Performance (Cleveland Power & Performance - Late-Model Car Parts, Restomod, Salvage Rebuilds, Custom Cars).

They take a short video of every turn-key-pallet they sell.

Good thing Dodge made a "race truck" from 04 to 06.

A Ram SRT 10 donates its Dana 60 HD rear axle (14" rotors with large two piston calipers) and parts of its front suspension (15" rotors with monstrous four piston caliper).

A D150 is about 3750 lbs, the 500bhp SRT-10 weighs about 5130 lbs.

It should be a fun truck with the Challengers 392 but i guesstimate it runs out of steam at around 150mph.

Any regular six cylinder Diesel station wagon does that in Germany.

I want more.

I want to brute force it to 170. But that's step two.

For step one this is the game plan:

- install Chevy C10 trailing arms (reinforced like on C20s) with coil springs.

I am in the process of making CAD drawings for the custom crossmembers.

It will be installed with a custom panhard bar, relocated shock mounts and a small sway bar

- fab and install frame-stiffening crossmembers, maybe tubular cross-bracing

- fab and install parts to adapt 05/06 Ram SRT-10 lower control arms, spindles and upper control arms and the rack and pinion steering.

- drop in the 6.4 with a Cherokee SRT-8 oil pan and make it work.

- have a specialized builder make a race-suitable cage (that will also stiffen up the chassis with rear and front outriggers

Also proper race seats, harnesses (regular street legal 3-point aswell) will be installed.

- carbon fiber bumper (moulding of the original part), carbon fiber hood (or at least air ducts for venting the engine compartment), etc.

I figure getting the 6.4 to work in my D150 is the most complicated part of this operation.

Everything else is precise measuring, fabbing parts and a bit of brainstorming through parts catalogues and Ebay.com

The 6.4 comes with an ABS-module for example. I can not re-use that with my truck, the calibration will not match the chassis behaviour OR the brake system so i need to get rid of that without disturbing the network of ECUs.

I wonder if there is a way to do that with say WiTech hardware and software.

Does anyone have experience with that?

One problem is:

I need to keep the original ECUs to make this thing road legal concerning emissions.

So there's no way of putting a Megasquirt Pro in the truck and running it that way.

This project would be a lot less fun if i could not make it road legal, so consider this a must-criteria.

So here it is... The Mr. Curtis project. Hope you like it.