Dave

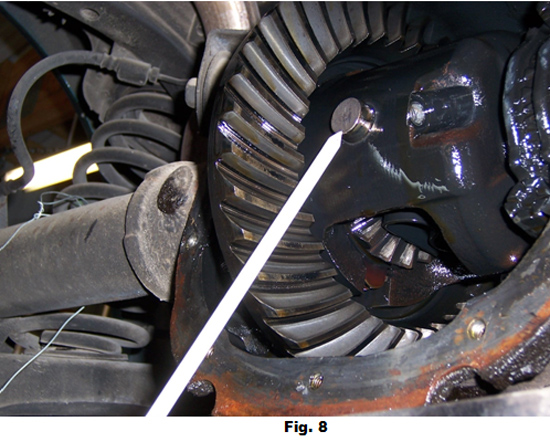

first off you have to find out if the spider gears and cross shaft can be saved ----they may be permanently welded to the cross pin --if so, you are sol as no one makes replacement spider gears or cross shaft and finding a good used set is ??????

if you can remove the spider gears from the cross pin if they are not too tore up the bore can be polished to make them serviceable again and you can use a cross shaft from an open diff to replace the damaged one.

if you can save the spider gears and get a shaft from a open diff -- finding a good machine shop to bush the case or weld up the holes and rebore them to size may be costly.

best bet is to buy a new aftermarket unit -- Power Lock , Auburn , True Trac , or a good used Power Lock clutch style unit to rebuild