sledger46

Well-Known Member

Hello all,

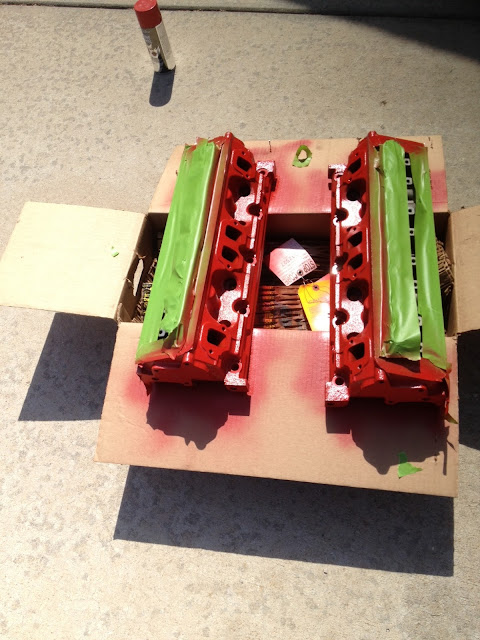

I recieved my new radiator and I swapped it in place of the old radiator.

I mounted my electric fan and heavy duty water pump. I gutted my old 180 thermostat to side step any thermostat not opening issues.

The fan flows 2400 CFM. It was the highest flowing fan I could find that would fit in the tight confines between the radiator and the water pump.

I used 2 bottles of Water Wetter and 3/4 of coolant with the rest being water. When I fired the car up and let it run for a few minutes the temperature settled at 140 degrees. A test drive on city streets resulted in a 185 degree reading back at the garage. A test drive on the highway at 3000 - 3200 RPM (55-60 MPH with 3.91s) resulted in 210 temps within 2 miles. It is getting hotter faster now when it is 85 degrees out then it did with the old radiator in 100 degree temps. I am pretty frustrated and stumped at this point. I guess I can try swapping back to the stock fan, but I don't have a shroud.

I recieved my new radiator and I swapped it in place of the old radiator.

I mounted my electric fan and heavy duty water pump. I gutted my old 180 thermostat to side step any thermostat not opening issues.

The fan flows 2400 CFM. It was the highest flowing fan I could find that would fit in the tight confines between the radiator and the water pump.

I used 2 bottles of Water Wetter and 3/4 of coolant with the rest being water. When I fired the car up and let it run for a few minutes the temperature settled at 140 degrees. A test drive on city streets resulted in a 185 degree reading back at the garage. A test drive on the highway at 3000 - 3200 RPM (55-60 MPH with 3.91s) resulted in 210 temps within 2 miles. It is getting hotter faster now when it is 85 degrees out then it did with the old radiator in 100 degree temps. I am pretty frustrated and stumped at this point. I guess I can try swapping back to the stock fan, but I don't have a shroud.