myduster360

Well-Known Member

I found an even tighter fitting bracket that looks better, cheaper too.

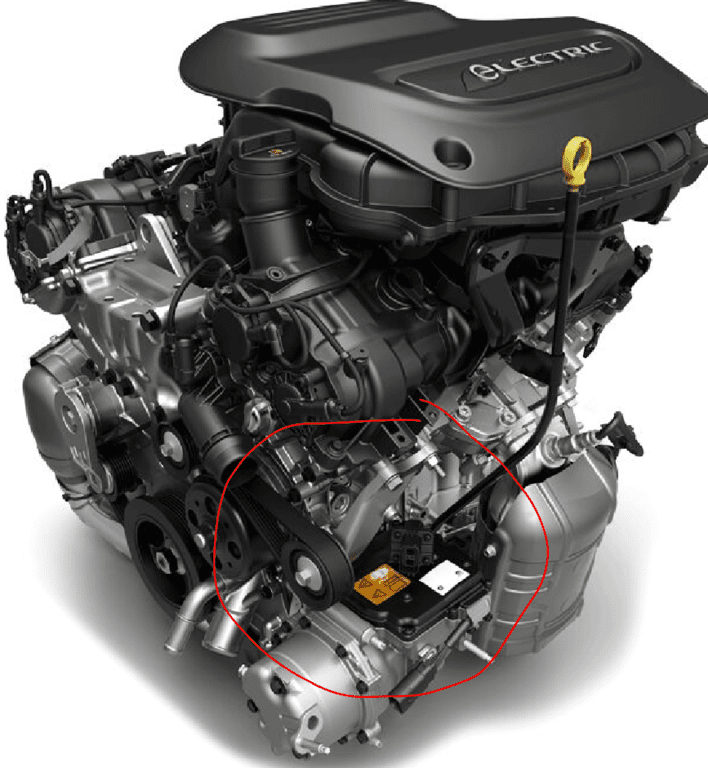

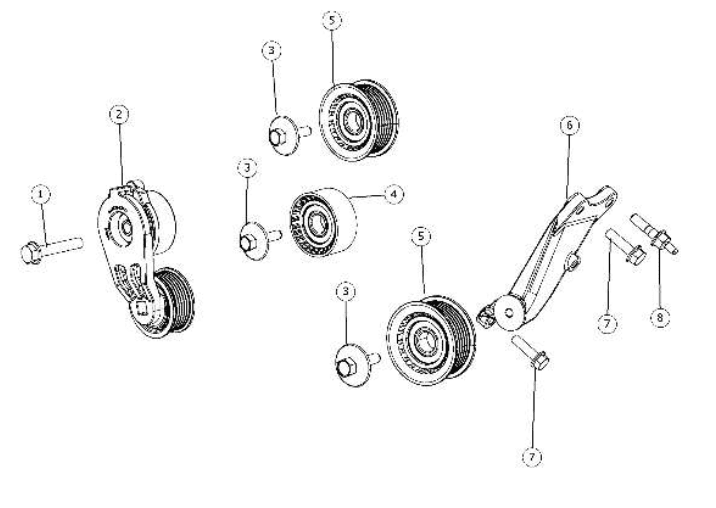

I was looking up info on the new 2017 3.6 Atkinson cycle Hybrid and noticed its sleek idler bracket. Its tucked in much tighter to the block.

Item #6 5281294AA BRACKET-IDLER PULLEY- $25

#5 5281301AA PULLEY-IDLER $30

#3 6510224AA BOLT-HEX FLANGE HEAD $2

I was looking up info on the new 2017 3.6 Atkinson cycle Hybrid and noticed its sleek idler bracket. Its tucked in much tighter to the block.

Item #6 5281294AA BRACKET-IDLER PULLEY- $25

#5 5281301AA PULLEY-IDLER $30

#3 6510224AA BOLT-HEX FLANGE HEAD $2