SpeedracerX

Still on this side of the dirt member

Under hood. That is. Damn autocorrect

this- love the way it looks in those pictures- great jobAWWWWWWWESOOOOOOOOME!!!!!! She looks GREAT Jerrod. WOWrayer:

rayer:

rayer::blob::blob::blob:

this- love the way it looks in those pictures- great job

you would think that a company as big as they are would be able to figure out how to ship something without damaging it... once I guess I could forgive, but twice? really? I would've been PISSED... but I am glad to hear they will at least refund you your money... maybe this is a sign your not supposed to have hood insulation? LMAO ..

Jerrod, you are da man. Looks great and look forward watching and learning more of what you are capable of.I am going to pm you with a praise of thanks for saving me money on something I would have never tried and thought of. Just don't want to high jack your thread cause it's not mopar related but I did it to my DD car. Love the updates keep them coming.

well guys, the weather has been pretty decent lately. And as promised.....I have been at it on the duster again! feels good!.

I first had to charge up the battery because its been sitting awhile...but once I let it charge for about 15 minutes she fired right up!. let it run for a bit. And then back it out of the garage so that I could spiff the garage up since its been used as a catch all for most of last fall and this winter.

Then I pulled it back in, jacked up the rear end and took the wheels off in preparation of truing up the rear end and installing new u joints (still havent replaced them since I exploded them last summer on a test run lol).

and thats about as far as I have got on that before I got side tracked lol....I ended up taking the grille out and grinding V's into all the cracks I found in it (wasnt to bad...had one large crack across the upper face of the grille and it had 5 cracked fins). I had a spare ford grille sitting in the shed that I cannibalised some tabs of plastic from. I then took out my soldering iron and melted all the grooves that I had cut and then added plastic from the tabs I had from the ford grille and used that melted plastic as a filler to flatten it back out. I then tested all the cracks and it all worked really well. I tried bending,twisting and prying on them all and they are just as strong as factory.

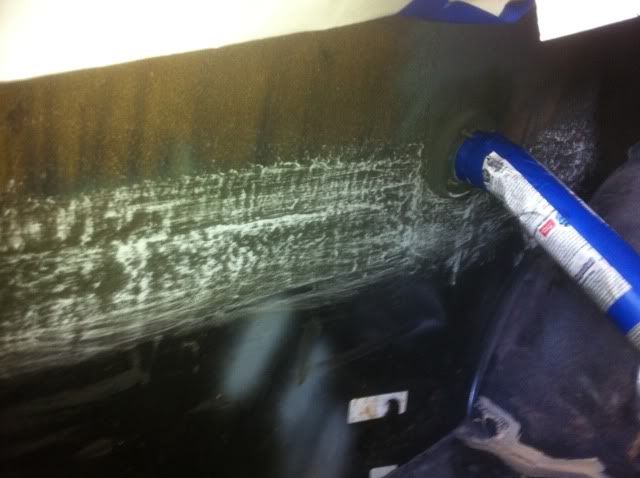

I then took my drill with a sanding disc and sanded all the work down nice and flat. once that was done I applied a smear of filler on the spots that I worked out. Then sanded the spots down and did some spot priming.

Its coming out really nice. I am about finished with it now. tomorrow I plan on trying to finish up all the body work on it and depending on how fast I get the work done and how ambitious I am feeling. I may go ahead and repaint it all tomorrow also.

so be sure to stay tuned because the updates will be coming again!!!

Also today....I finally got the Duster insured for the road ( thats how close she is to being ready lol). Got a really good deal through grundy insurance for $160.00 a year for full coverage with a $20k agreed value.

so anyhow...basically...the grille should be done soon,then I need to polish the chrome trim that goes on it, then need to polish the head light bezels and then mask off the centers and respray them. Then I need to mount headlights, finish mounting in hood latch assembly. I need to do a fresh oil change, maybe some plugs since its had alot of idle time and alot of carb tweaking done on these plugs so I am sure they are probably pretty sooty. I need to fix an upper radiator hose that keeps leaking at the water outlet. I am probably going to run all new fuel line since I have a new spool of aluminized sitting on the shelf anyhow. I may down size gears in the rear because I think the 4.56's might be a bit to much for what im looking for.

Ive got to get a new kick down cable and install it, need to install new u-joints and true up rear end, I will probably put all new bearings in the rear and axles if/when I do gears. I need to put new bumper bolts in. a couple little interior peices. And I need to buff out the top of the car still where we didnt get around to it after paint.

so there is still quite the "to do list" but most of it is odds and ends and hopefully wont take alot of time.

sorry for the long post guys but its been awhile since I really got to post anything of interest and im just excited to share it with you all. Almost 4 years since I bought the duster and im just now nearing the completion ( Ill always be able to pick things on it apart and find something else that needs done of course lol. but for the most part it will be complete).

Heres some pictures for you guys for right now. stay tuned!

before pictures

after carving out the crack

missing tab

another crack

another crack

replaced the missing tab

corner of this tab was missing, so i made my own.

back side of the worste crack after I did a bit of plastic filling on it.

another tab that was missing, so I made my own and patched it in.

the visible side of the worst crack just after I did some plastic filling

some of the fin supports that had cracks after I plastic welded them

one of the cracks on the top after I did some plastic filling

sorry guys, I forgot to take pictures during the sanding of the plastic and of applying the body filler.

But as you can see " CRACK BE GONE" LOL....this is where the worste crack was.It went all the way through the front,back,and through the lowest fin.

and heres a closer picture of it

I still have to sand the primer down along with the rest of the grille when I prep it for paint...but it should all come out looking really nice. dont let the "before" pictures fool you lol. I know some of it might look ugly. but just you wait and see lol.

And here is a couple of pictures of the duster when I first backed it out of the garage (its dusty) but sure is purdy lol.

stay tuned guys and dont be shy to chime in!