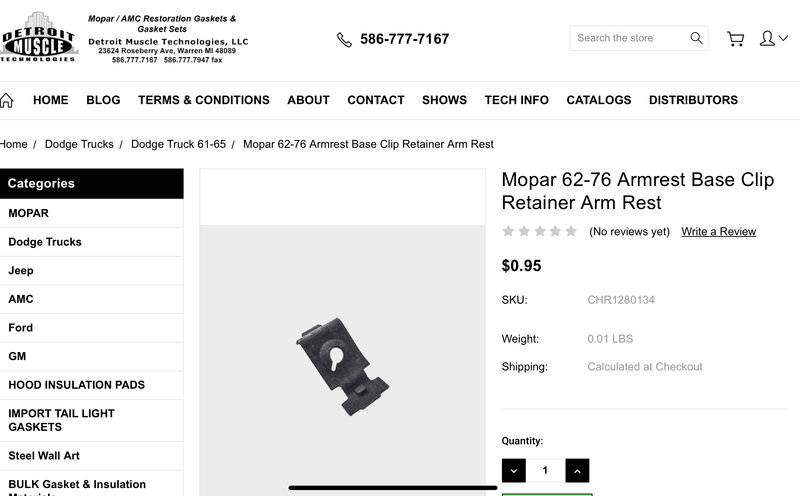

Need suggestions vs enlarged holes in door panel sheet metal which won’t hold the arm rest. I ordered the clips in the picture but, with panel removed, I don’t see any way to keep clips in place on the back side of the metal. Back side of door’s sheet metal is very difficult to reach.

Would it be feasible to tac weld a thin piece of metal (maybe a flattened base clip retainer)?

A complicating factor is that the screws come thru the armrest with an upward angle (see 3rd photo.

Would it be feasible to tac weld a thin piece of metal (maybe a flattened base clip retainer)?

A complicating factor is that the screws come thru the armrest with an upward angle (see 3rd photo.