demon seed

The Original Demon Seed

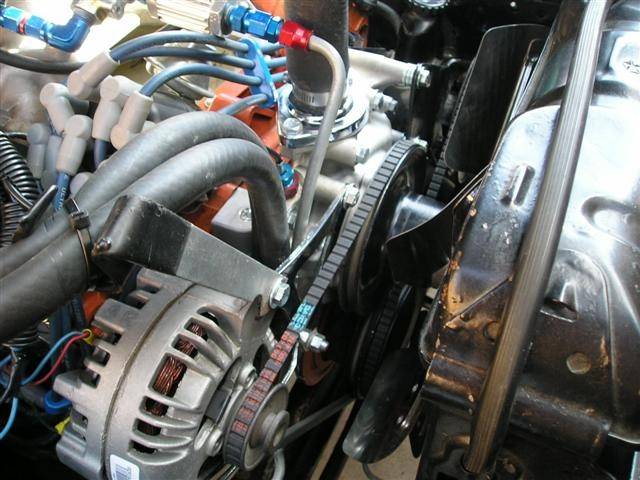

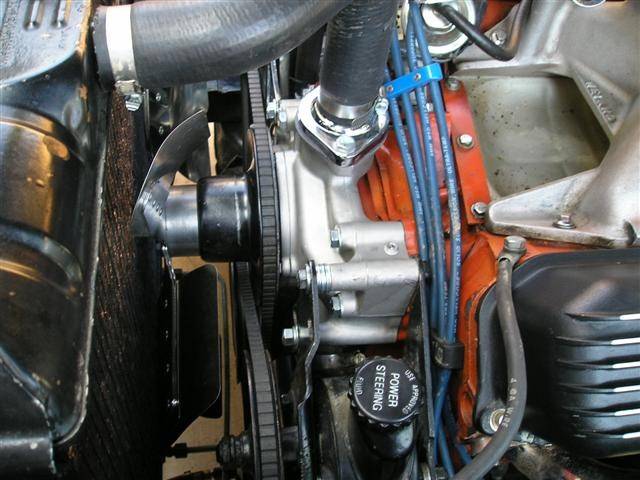

Well, all this crappy weather has allowed me to get some work done on the beast. Got rid of the old cast iron pump (blown seal) and installed a new high volume unit which I'm hoping will also cure a slight cooling problem in stop and go. Fired her up and no leaks and she comes right up to 180 and sits there now all I need is some hot days to see how good it works. While I was at it I also scrapped the old 727 oil pan (easy to drain the oil when you drill a 1/8 hole in it and no mess) and put on a 3 inch deeper aluminum pan from Summit, looks nice.

Terry

Terry