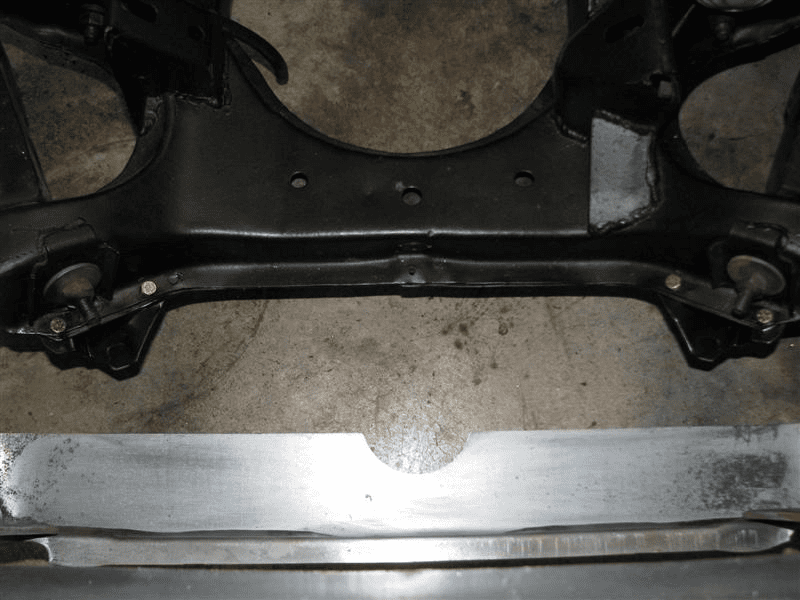

I dropped my k member and bumper brackets off at the local sandblasting company as they were a little big for me to do. After 3 weeks of waiting and getting told they would call me when they were done I drove down as I feared they had gotten lost. I found them on a pallet in the snow blasted and rusting. They had been sitting 2 weeks. They dusted them off for me. Those factory welds (I assume) are horrible.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blasting k member & factory welds

- Thread starter 1MeanA

- Start date

-

Rat Bastid

Dunamis Metron

Typical. Grind down the real ugly **** and weld them up. You can get stiffening plates. I think they are worth it.

The K-frame out of my 70 Duster, looked like it was formed between 2 rocks, and the welds done underwater, by Stevie wonder....with a caulking-gun.

You're giving that welder a whole lot more credit than I would.....

mopowers

Well-Known Member

The good news is that it's in a great position to grind them out a little and buzz some new solid welds over them.

Last edited:

Dfr360cuda

Diagnosis... Plum Crazy.

I would grind out that porosity and dress up all the welds.

Good time to powder coat it too.

Good time to powder coat it too.

I like to say 'banged out on a picnic table'. I just put it in epoxy primer for now along with the bumper brackets, splash shields and lower control arms.The K-frame out of my 70 Duster, looked like it was formed between 2 rocks, and the welds done underwater, by Stevie wonder....with a caulking-gun.

Last edited:

They are all like that. Good advice to grind and weld. Just keep everything cool as you work to avoid warping.

We did the same on my K member. Grind and clean up the welds, no stiffing plate. We did tack on a flat washer so that snoopers will think it's an 340 K member.

-