Trevor B

Well-Known Member

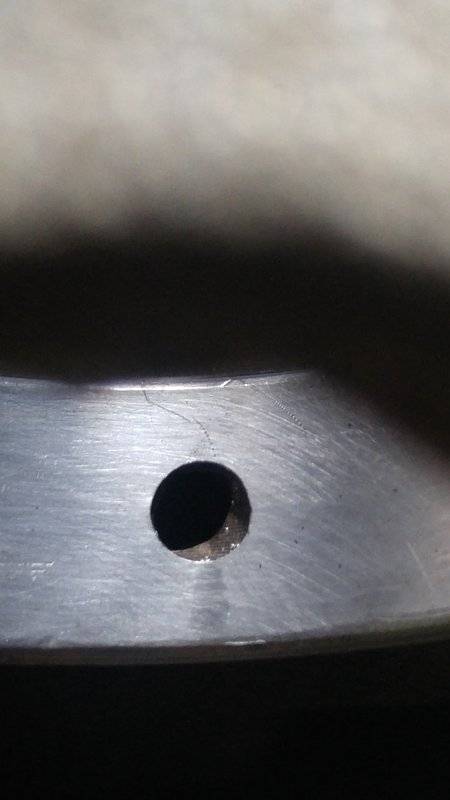

Just got my 360 block back from the machine shop and was going to begin assembly when I noticed that the 2nd cam bearing hole was not perfectly aligned. The machinist installed the new cam bearings. Is this a deal-breaker?