Cal_gecko

Citron Yella!!

I feel like I may have made some progress tonight..

First off - I stopped by the auto parts store to picked up a new cap/rotor.. while I was there, ran into a nice guy with a sweet 440-powered Fury.. this thing was cool.

Anyways.... he and I chatted too long, and the parts store closed.. so I went across the street to Autozone and got my cap/rotor...

Came home, swapped it out, no noticeable improvement.

Next step: put markings on the harmonic balancer so I could avoid using the dial-back light .. I'm hearing that they don't always work well with MSD boxes. Adjusted idle timing to about 16 degrees advance, checking with both my dial-back light as well as a regular (non-dial) timing light to ensure they both read the same.

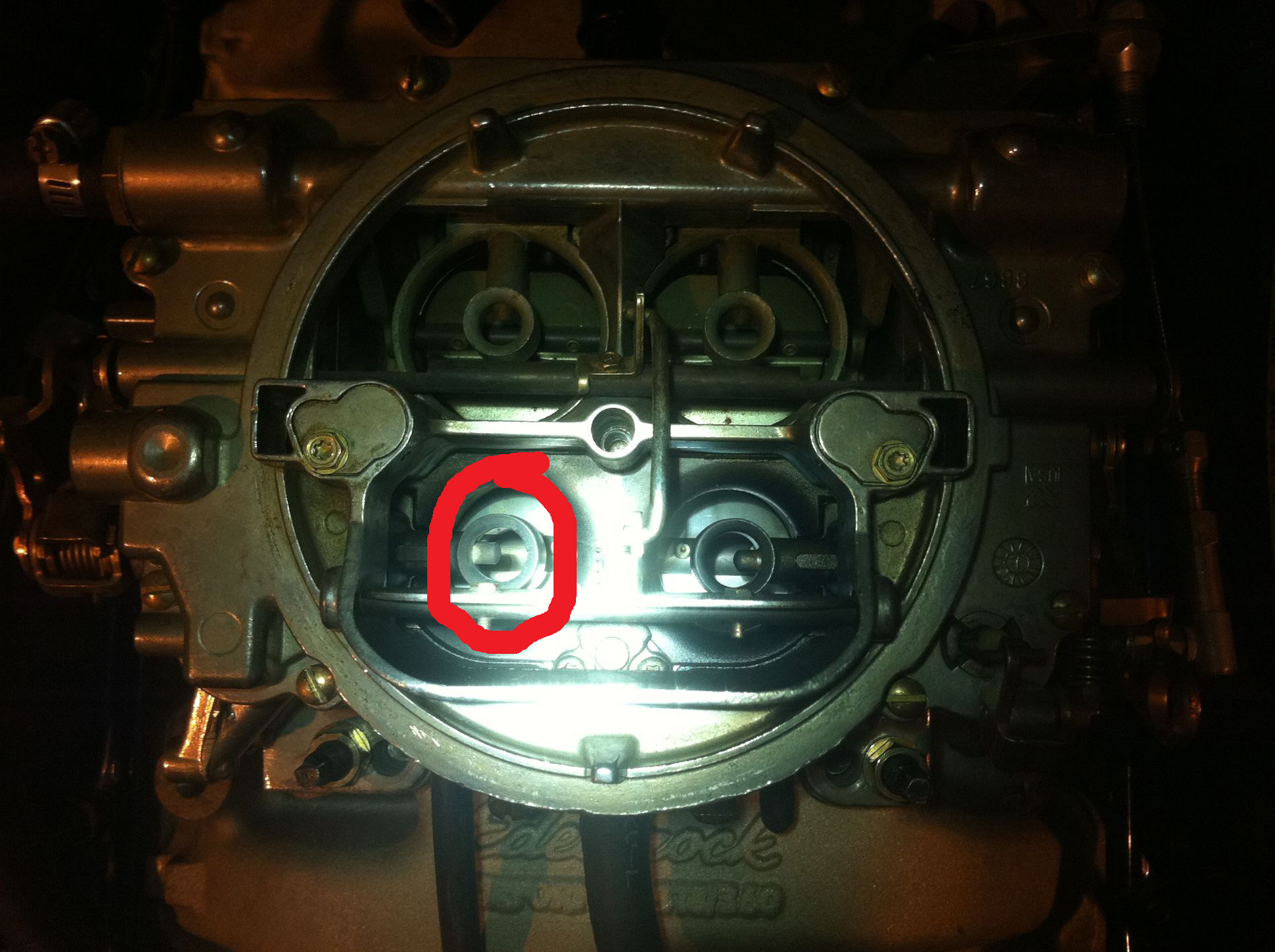

I kept backing out the a/f screws until my vacuum started to increase, and it seemed to make an impact to how it ran. I had to back them out to about 2.5 turns out, but it seemed to start making a difference. I was able to get the idle speed screw backed off a bit.

I am running a Holley blue fuel pump along with a Holley pressure regulator and a fuel pressure gauge .. no return line. At idle, the pressure does build up a bit .. it 'creeps'.. so I know I have to give it a few blasts of throttle to bring the pressure back down. Anyways, during the process tonight, I gave it some good blasts of throttle, and held it at a higher RPM range for a little bit...

Next thing I know, it's holding an idle better than I've seen so far...

Am I finally making progress?

[ame=http://www.youtube.com/watch?v=UULdvZc8vqs&list=UUI3o1I0V0CJXfOmuCbQdUdg&index=1&feature=plcp]http://www.youtube.com/watch?v=UULdvZc8v...mp;feature=plcp[/ame]

Keep in mind - exhaust is total overkill - headers to 3" exhaust and turndowns.. .so exhaust is pretty loud.. I'll be getting a proper exhaust system installed when it's done.

First off - I stopped by the auto parts store to picked up a new cap/rotor.. while I was there, ran into a nice guy with a sweet 440-powered Fury.. this thing was cool.

Anyways.... he and I chatted too long, and the parts store closed.. so I went across the street to Autozone and got my cap/rotor...

Came home, swapped it out, no noticeable improvement.

Next step: put markings on the harmonic balancer so I could avoid using the dial-back light .. I'm hearing that they don't always work well with MSD boxes. Adjusted idle timing to about 16 degrees advance, checking with both my dial-back light as well as a regular (non-dial) timing light to ensure they both read the same.

I kept backing out the a/f screws until my vacuum started to increase, and it seemed to make an impact to how it ran. I had to back them out to about 2.5 turns out, but it seemed to start making a difference. I was able to get the idle speed screw backed off a bit.

I am running a Holley blue fuel pump along with a Holley pressure regulator and a fuel pressure gauge .. no return line. At idle, the pressure does build up a bit .. it 'creeps'.. so I know I have to give it a few blasts of throttle to bring the pressure back down. Anyways, during the process tonight, I gave it some good blasts of throttle, and held it at a higher RPM range for a little bit...

Next thing I know, it's holding an idle better than I've seen so far...

Am I finally making progress?

[ame=http://www.youtube.com/watch?v=UULdvZc8vqs&list=UUI3o1I0V0CJXfOmuCbQdUdg&index=1&feature=plcp]http://www.youtube.com/watch?v=UULdvZc8v...mp;feature=plcp[/ame]

Keep in mind - exhaust is total overkill - headers to 3" exhaust and turndowns.. .so exhaust is pretty loud.. I'll be getting a proper exhaust system installed when it's done.