megavites

Well-Known Member

help me understand what step I might be missing. In another thread New rebuild....but tic..tic...tic

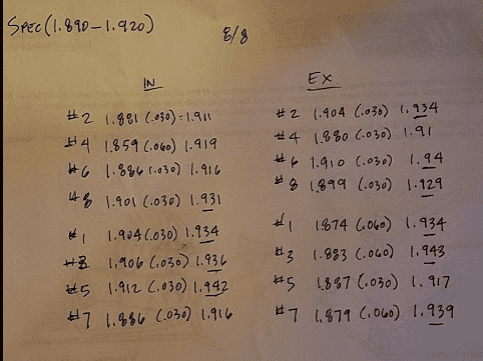

I explain my new build with all new valvetrain. I measure valve lash w/rockers at:

Intake Exhaust

#2(0) #8(0)

#1(.003) #4(0)

#8(.003) #3(.017)

#4(.006) #6(.043)

#3(0) #5(0)

#6(0) #7(.011)

#5(.012) #2(.014)

#7(0) #1(0)

so I measure valve stem height and add spring shim and oddly enough, my taller valvestems also have the biggest valve lash gap?? Seems opposite of what it should be??

When I measured lash, I bumped motor until no movement on that rocker to be sure its on basecircle. Rotating 90 deg and measureing was not putting next valve on base circle,

I presume due to custom performance cam (whiplash).

So I have .032” spread from on valvestems and anywhere from zero lash to .043 gap at rocker. Preload should be .080-.085.

IF I go with a .075” longer pushroad, preload would range from .032 to .075.

Is there anyway around this other than adjustable roller rockers to take up the slack?

I’m going to re-check again (Vernier depth gauge) the stem heights as I did vary by .020-.030 with my measurements when rechecking each measurement.

I explain my new build with all new valvetrain. I measure valve lash w/rockers at:

Intake Exhaust

#2(0) #8(0)

#1(.003) #4(0)

#8(.003) #3(.017)

#4(.006) #6(.043)

#3(0) #5(0)

#6(0) #7(.011)

#5(.012) #2(.014)

#7(0) #1(0)

so I measure valve stem height and add spring shim and oddly enough, my taller valvestems also have the biggest valve lash gap?? Seems opposite of what it should be??

When I measured lash, I bumped motor until no movement on that rocker to be sure its on basecircle. Rotating 90 deg and measureing was not putting next valve on base circle,

I presume due to custom performance cam (whiplash).

So I have .032” spread from on valvestems and anywhere from zero lash to .043 gap at rocker. Preload should be .080-.085.

IF I go with a .075” longer pushroad, preload would range from .032 to .075.

Is there anyway around this other than adjustable roller rockers to take up the slack?

I’m going to re-check again (Vernier depth gauge) the stem heights as I did vary by .020-.030 with my measurements when rechecking each measurement.