Serj22

Well-Known Member

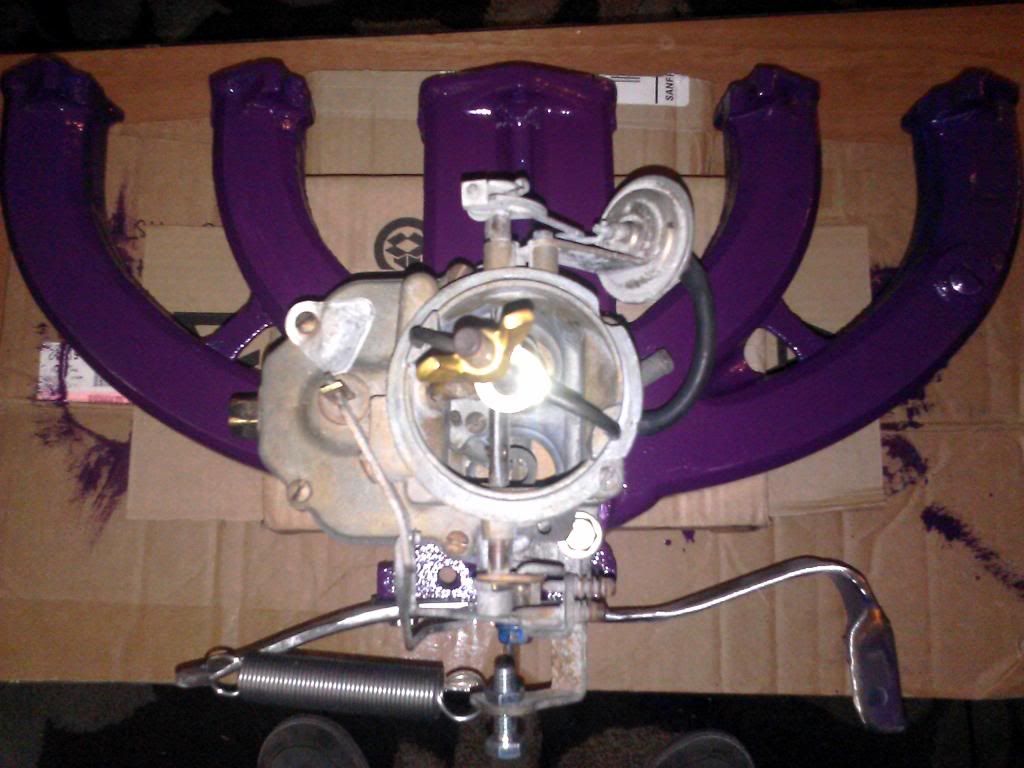

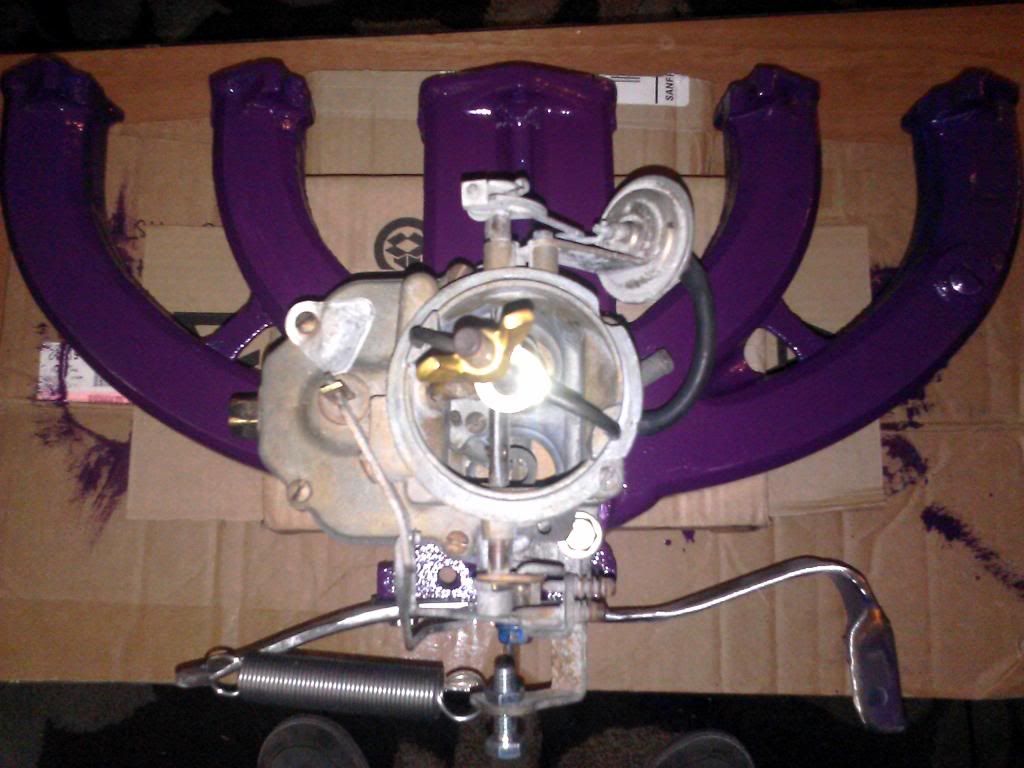

So, I decided to give up crying about not having the money I needed to complete my super six intake and just pick up a grinder and do something with my life.

I realized I should have bought the entire setup rather than piecing it out, but I have an exhaust manifold and intake, etc... to work with now, so I'm going to use them. I did not have the return spring hook, or a kickdown with the throttle mount on it or an EGR... so I made one out of 2 old battery tie downs for a golf cart, and some old chunk of 3/8" steel. I like it considering I have no real clue how to work with metal. I went off some basic measurements some others posted who had the real equipment or another homemade design. Perhaps you see something though that needs to be altered?

Here's the question. The choke needs to be converted to electric or manual it seems to easily finish and then figure out a home-made kickdown. IS IT POSSIBLE, that the location where the EGR would be, would create enough heat to move a coil-type choke like what was originally on it? If so, maybe I could drill a hole to it on the block off, make another bracket for it to hold the coil and make a rod to push straight up on the choke lever on the same side as the throttle? (long question... I know) But I could possibly make a 4 bird/one stone part...

Here's what I made so far.

I realized I should have bought the entire setup rather than piecing it out, but I have an exhaust manifold and intake, etc... to work with now, so I'm going to use them. I did not have the return spring hook, or a kickdown with the throttle mount on it or an EGR... so I made one out of 2 old battery tie downs for a golf cart, and some old chunk of 3/8" steel. I like it considering I have no real clue how to work with metal. I went off some basic measurements some others posted who had the real equipment or another homemade design. Perhaps you see something though that needs to be altered?

Here's the question. The choke needs to be converted to electric or manual it seems to easily finish and then figure out a home-made kickdown. IS IT POSSIBLE, that the location where the EGR would be, would create enough heat to move a coil-type choke like what was originally on it? If so, maybe I could drill a hole to it on the block off, make another bracket for it to hold the coil and make a rod to push straight up on the choke lever on the same side as the throttle? (long question... I know) But I could possibly make a 4 bird/one stone part...

Here's what I made so far.