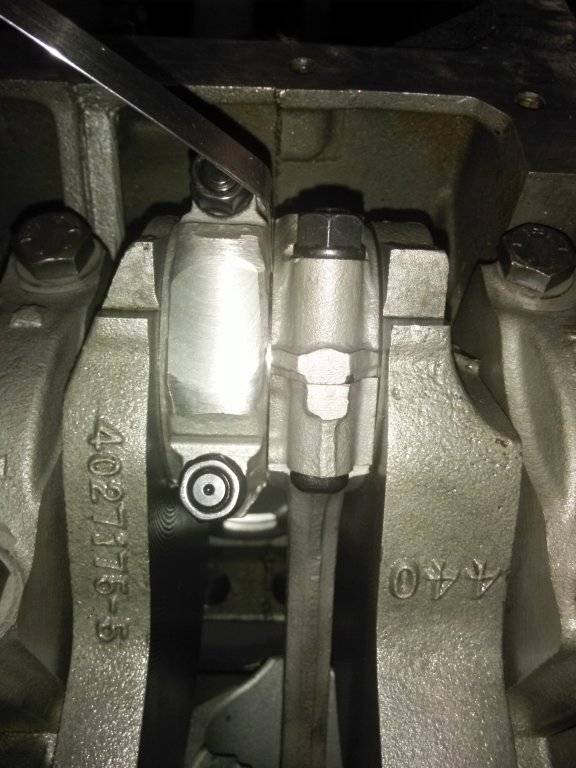

Had I known better I would have taken some general measurements before disassembly, now Im putting some things together and I notice the connecting rod clearance is real wide on the front and rear 2 apposing cylinders, ( #1 n 2 and 7 n 8 ) I can slip a .030 feeler gauge in there pretty easily and thats the largest I have.

Its already all been balanced, new ARP rod bolts installed ect so buying new rods cause these have been ground isnt something Id like to do but if I must.

Supposed to be 7-17 according to the book I have.

Its already all been balanced, new ARP rod bolts installed ect so buying new rods cause these have been ground isnt something Id like to do but if I must.

Supposed to be 7-17 according to the book I have.