MObarracuda

Well-Known Member

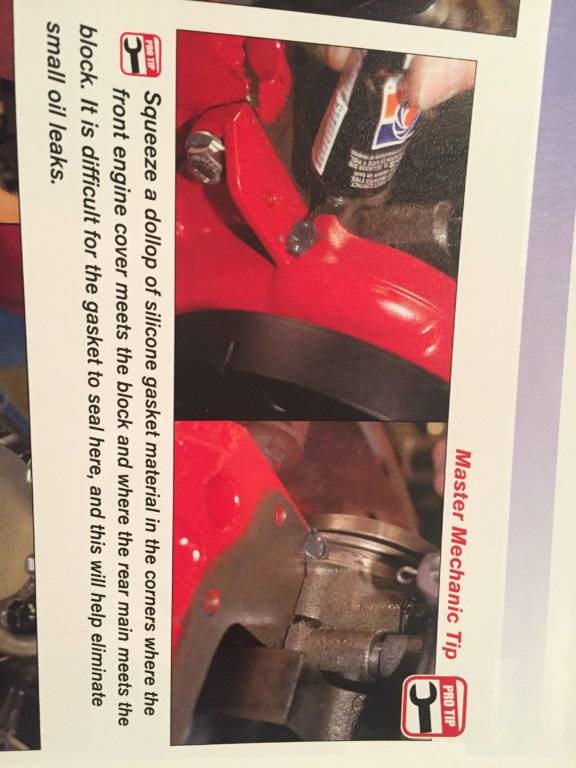

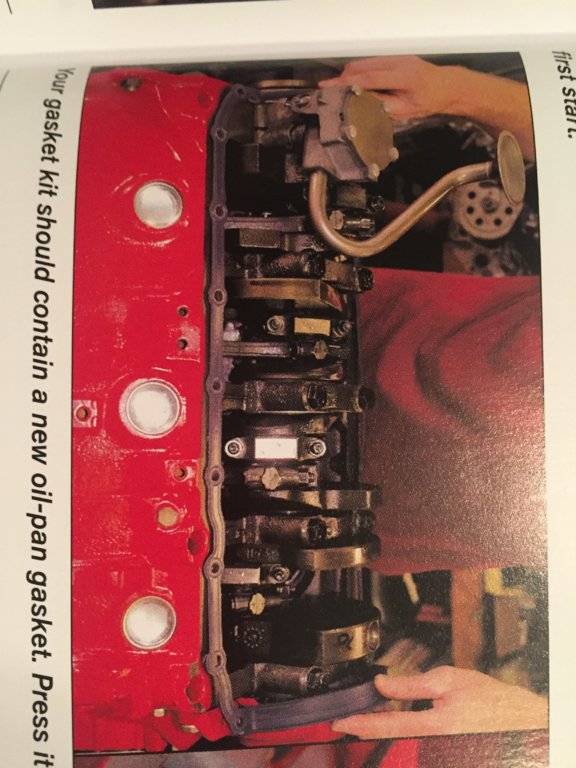

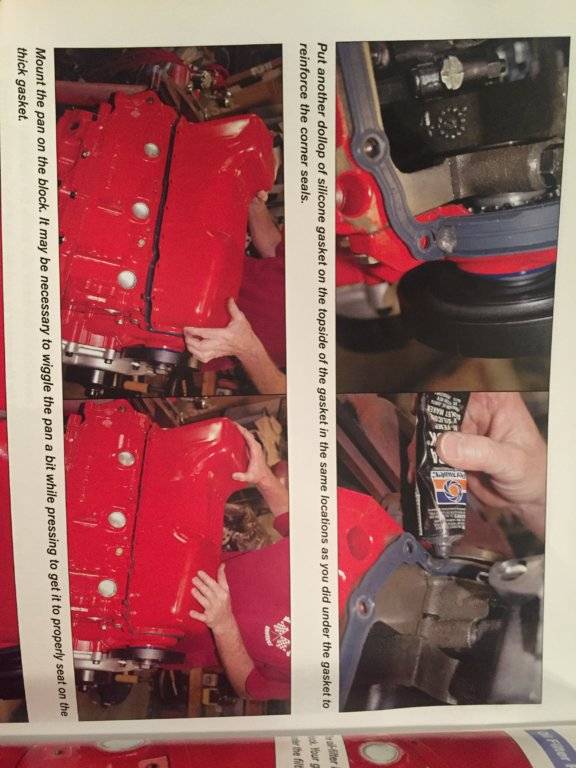

I'm about to put my stroked 340 back together. It will be my 2nd career motor assembled in my 48 years. The mopar book I purchased as a refresher and guide does a good job of covering the difference between the magnum and LA engines. But the book shows only the magnum one piece oil pan gasket example.

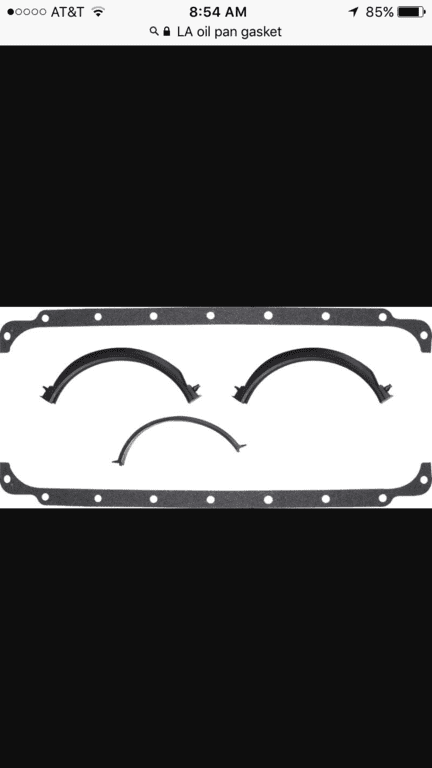

What procedure do you guys/gals follow with the paper/composite LA (4) piece design to avoid leaks. Do you install it dry and only apply sealant at the corners or do you apply sealant to both sides of the gasket and the corners?

I want to know what procedure you have had success with in the past.

What procedure do you guys/gals follow with the paper/composite LA (4) piece design to avoid leaks. Do you install it dry and only apply sealant at the corners or do you apply sealant to both sides of the gasket and the corners?

I want to know what procedure you have had success with in the past.