octanejunkie

Mopar Padawan

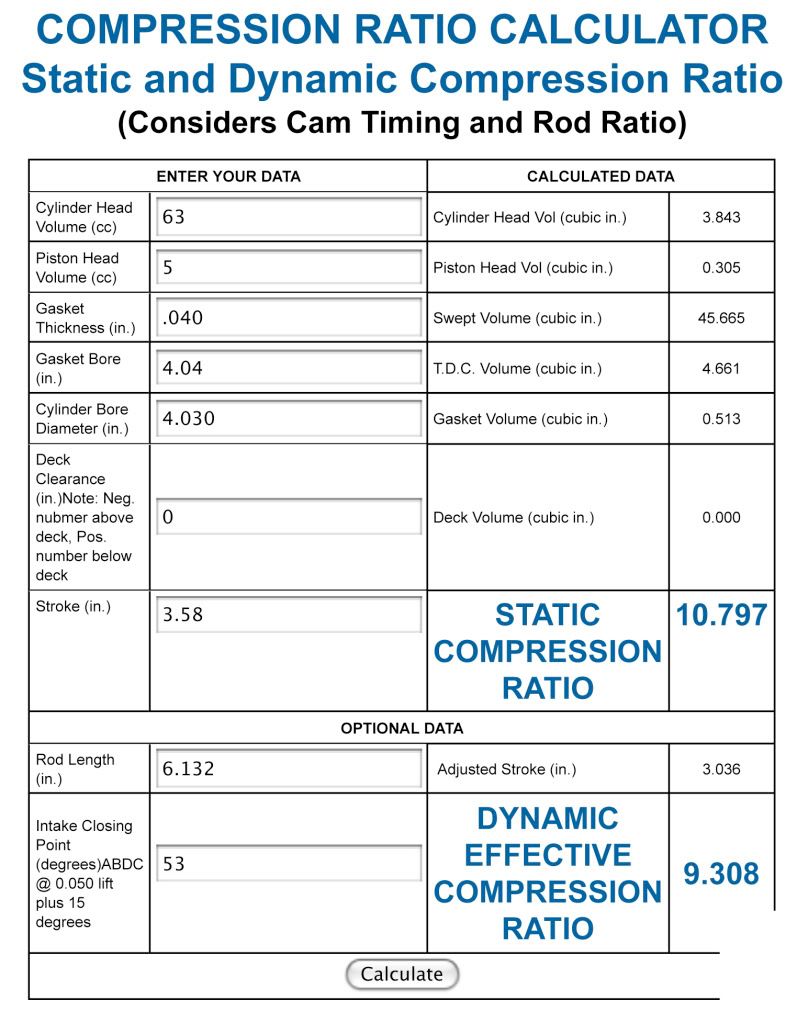

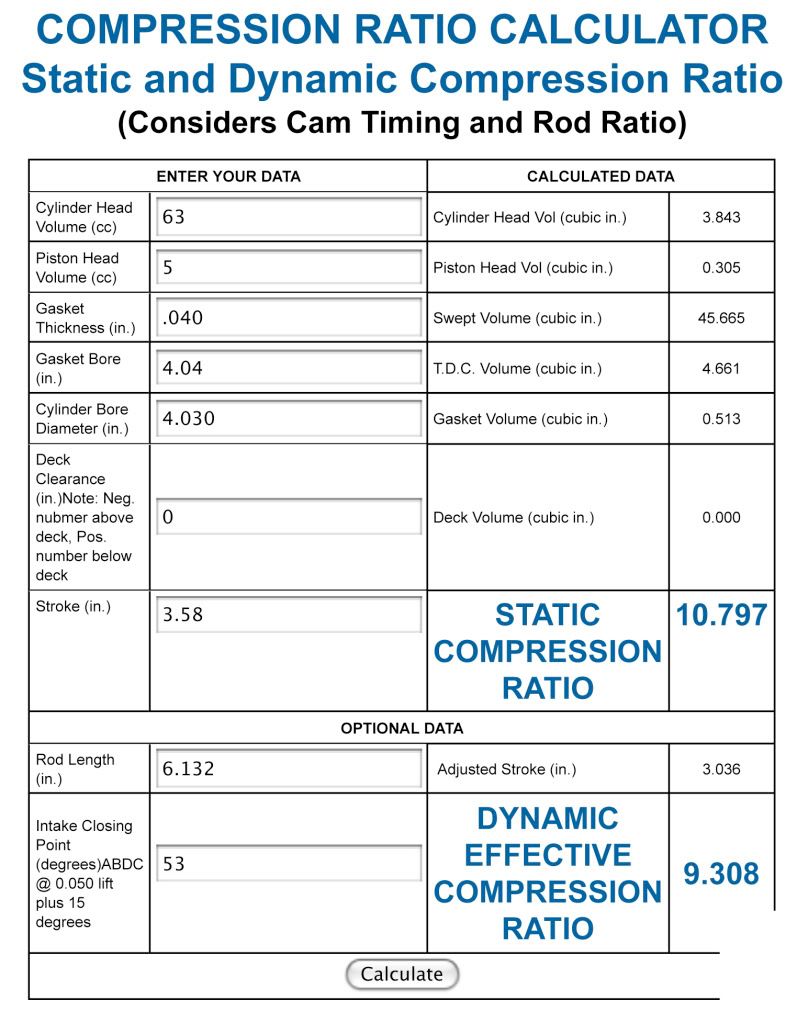

OK so after much-ado about quench and what not, here is the workup I did on kb-silvolite.com using a $180 worth of Cometic head gaskets, I guess felpro's .040 compressed thickness will work too and lower the CR a wee bit with it's larger bore diameter

.

.

I'm obviously going for optimal quench so the SCR doesn't bother me too much, but the DCR seems high... commensurately so using the XE268H's IVC of 38 plus 15 degrees

I estimated my chamber volume for stock magnum 360 heads cause I haven't CC them yet, appreciate any input here

.

.

I'm obviously going for optimal quench so the SCR doesn't bother me too much, but the DCR seems high... commensurately so using the XE268H's IVC of 38 plus 15 degrees

I estimated my chamber volume for stock magnum 360 heads cause I haven't CC them yet, appreciate any input here