JimDuster71

New Member

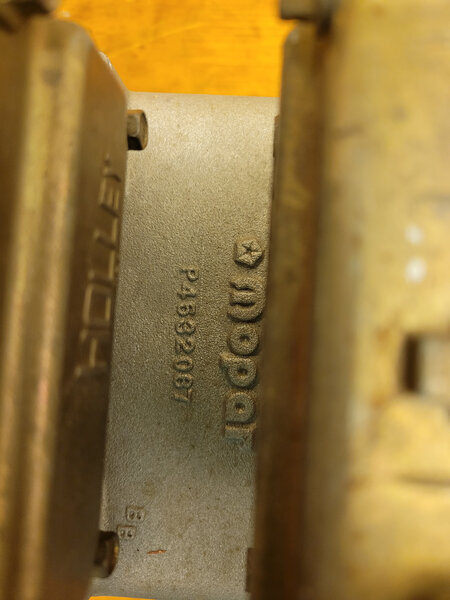

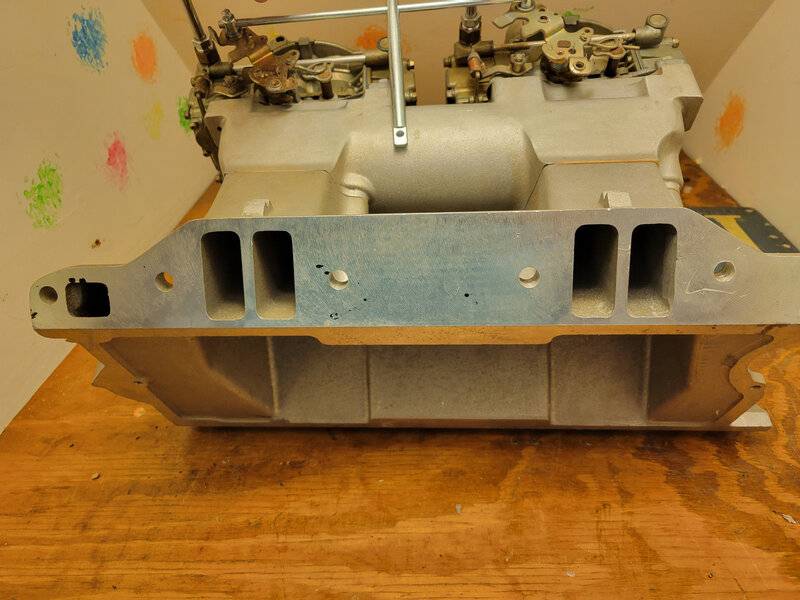

I bought this Tunnel Ram years ago thinking it would would be nice on a future build. Well looking to build a nice SB so while doing research I read that the tunnel ram is only for W2 heads. Looking at W2 heads intake ports they look to be OVAL but looking at the ports of the tunnel ram they are rectangular....... What am i missing?