SoulSurvivor

Well-Known Member

My machine shop let me use their pushrod measuring tool to determine which size push rod to buy. Is there a write up or experience here that I could gleen from you guys? Thanks, Doug

I have stainless adjustable rockers and a hydraulic cam. I just can remember how to do the measurement

No. The stock pushrods are too long. And yes..that is what I am trying to do..just get what fits between the lifter and rocker. I am going from the stock rocker assembly to a roller rocker assembly. With the stock pushrods installed the roller rocker assembly 'floated' above the mounting valleys by 1/4 inch. 2 of the pushrods were preventing me from tightening the shaft down secure. Even when the adjusters were backed out as far as they would go. I just have to get the right pushrods. Make sure they fit. And make sure the length is right for the roller to travel across the valve tip properly.The tool is too long?

Take a picture of you set up and post it.

Don't worry about preload or anything else at this point. All you care about is getting a static measurement of what will fill the gap between lifter and rocker..

You have to pull ALL the pushrods out on the side you are going to check.

All you need installed is the pushrod checker, one rocker shaft and two rocker arms. You can check multiple locations.

You have to pull ALL the pushrods out on the side you are going to check.

All you need installed is the pushrod checker, one rocker shaft and two rocker arms. You can check multiple locations.

I generally will trust the measurement on just one cylinder (or one on each bank of cylinders) if the valves all have the same installed height.

If you want to be really assured that you are good, you can check them all. It will only cost you a little extra time and might save you some, for sure!

If the valves installed height varies, you should address this issue at this time also....new valves and good valve job.

What brand are the rockers?

I agree that one spot is all that is needed.

Some people are a little more anal about thing. Needn't measure more than one spot, especially with adjustable rockers.

Yes. I would take it to a store that sells dial claipers big enough to measure it and then add the .050" to the measurement. Your machine shop will have a set to measure them with. I have an extra set of ball and cup pushrods sitting here because I didn't do it right years ago. I guess I can call them brand new wrong old stock! LOL

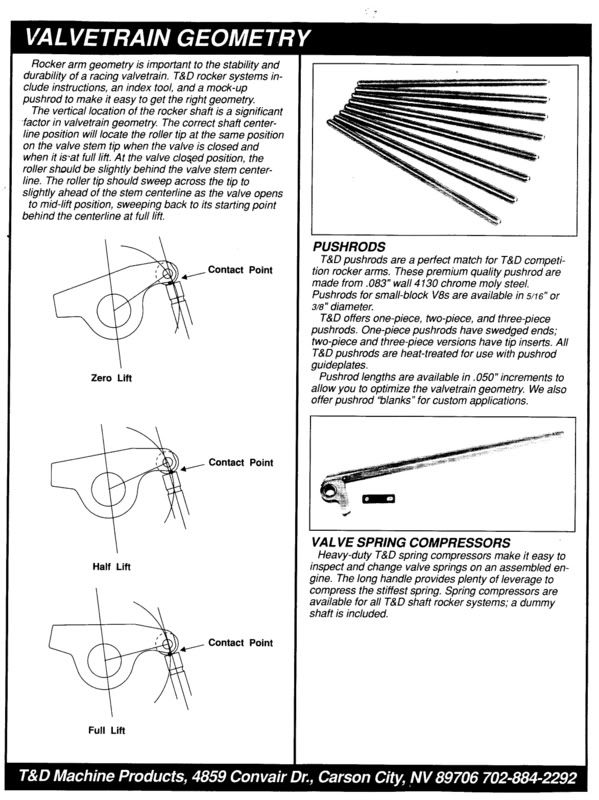

P.S. Did it make the sweep back at full lift?

I made one out of an old pushrod.