A question only you can answer. That depends on the extent of the rust and your level of experience/ability. A complete novice with limited time to work on their project might be better off buying a patch panel for their specific car. Obviously would be cheaper to make your own. Buy a sheet of metal and watch a bunch of Youtube metal working videos. Make a pattern of your patch before committing it to metal. I use 12 pack pop/beer boxes sometimes to make my patch patterns. You really need a welder and a flux core unit won't work worth a crap on sheetmetal.I guess the question now is can I fabricate my own patches or do I need to buy panels?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rust Repair Maiden Voyage

- Thread starter rich006

- Start date

-

rich006

Learning as I go

I might break down and buy a MIG welder. That's the kind of thing I probably wouldn't regret. But I might regret not doing it.

GeorgeH

Well-Known Member

Your better off to weld it. Never been a big fan of the panel adhesives. Have seen what happens when cars fixed that way have been bumped again, and have seen the seams show back up when used on exterior surfaces.

rich006

Learning as I go

My original goal was to stop the rust from spreading without doing a lot of metal replacement. With the extent of the rust I've found, I know the correct fix is to weld in a new lower quarter and a new trunk extension (drop off). However, I don't want to spend the money or time on that this year. Instead I'm going to try a temporary fix that I hope will last a number of years and if/when it fails I'll still be in the same position, namely needing to weld in a new quarter and trunk extension. My new plan is to treat the insides with rust reformer and then patch the holes from the inside with fiberglas (mat and/or woven) and epoxy resin.

I have over 20 years experience welding in shipbuilding. If you are new to welding, you do not want to learn on a patch panel that everyone is gonna see. Go ahead and get a pro to do it for you. Once you've had some practice on other stuff, then you might want to try it. It's not as easy as the TV shows make it look on thin material, especially if you're new, and it's hard to hide mistakes with grinding and bondo.

rich006

Learning as I go

On both sides of the car it seems the rust spreads downward and rearward starting from the joint where the trunk extension, inner quarter, and quarter skin come together. Does anyone know why it starts there?

GeorgeH

Well-Known Member

Sand gets packed in there and holds moisture, the seams and pinchwelds don't always get sealed up under there

GeorgeH

Well-Known Member

I have over 20 years experience welding in shipbuilding. If you are new to welding, you do not want to learn on a patch panel that everyone is gonna see. Go ahead and get a pro to do it for you. Once you've had some practice on other stuff, then you might want to try it. It's not as easy as the TV shows make it look on thin material, especially if you're new, and it's hard to hide mistakes with grinding and bondo.

Don't scare the guy! lol

rich006

Learning as I go

Sand gets packed in there and holds moisture, the seams and pinchwelds don't always get sealed up under there

So would it help to spray some rust reformer up into the seam from beneath? I'm mainly thinking about my left side, where it's still just a small spot bubbling up. I don't want to cut into that side if I can slow the rust from the inside somehow. (The first 2 photos in the thread show what I'm talking about.)

GeorgeH

Well-Known Member

Not sure what reformer your using. I use Ospho or Rust-mort which is very thin, and Can be put in a spray bottle and soak it a couple times.

rich006

Learning as I go

I have a spray can of Rustoleum rust reformer.

GeorgeH - LOL -don't mean to scare him at all. Just want him to realize it's not like TV where the guys hook up their welder and go to town. It takes a bit of practice to learn to weld sheet metal. Better to practice - like on a floor pan - and then tackle the stuff everyone is gonna see.

rich006

Learning as I go

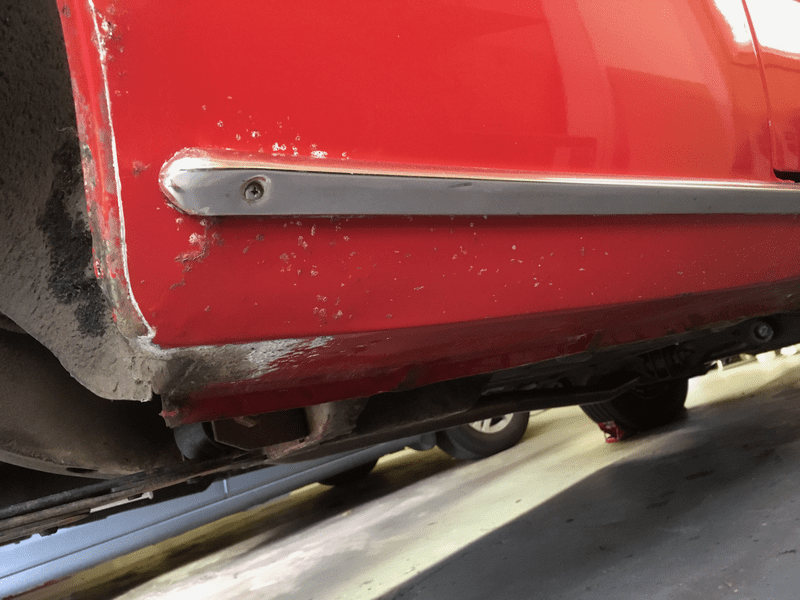

There's also a rotting area at the rear of the rocker panel.

I found a one-inch rotten spot on the wheel house, barely visible until I started poking at it.

Looking in the new hole, I could see the rocker is rusting from the inside out--as many FABO'ers could have told me.

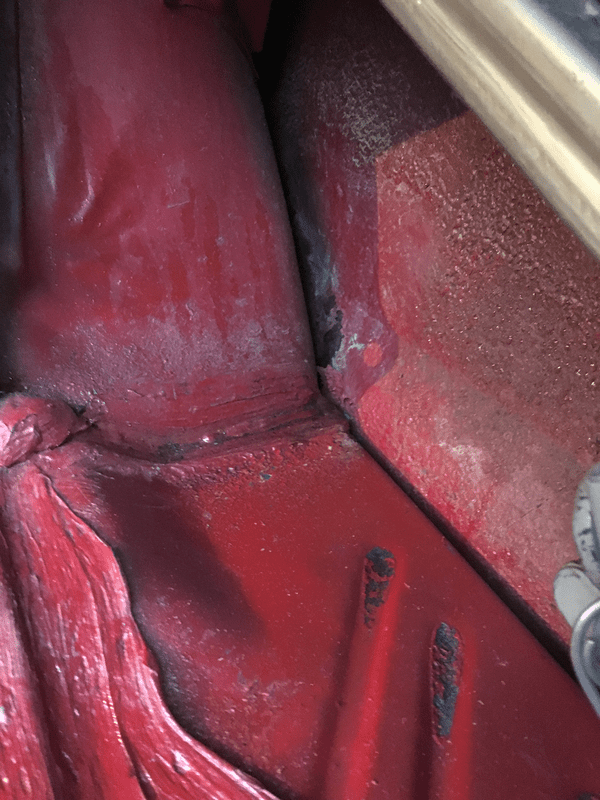

I also found I could see the quarter panel rust from the inside of the trunk, once I knew where to look--right where the wheelhouse, trunk extension, and quarter skin meet, on both sides of the car. Here's the left side.

And on the right side.

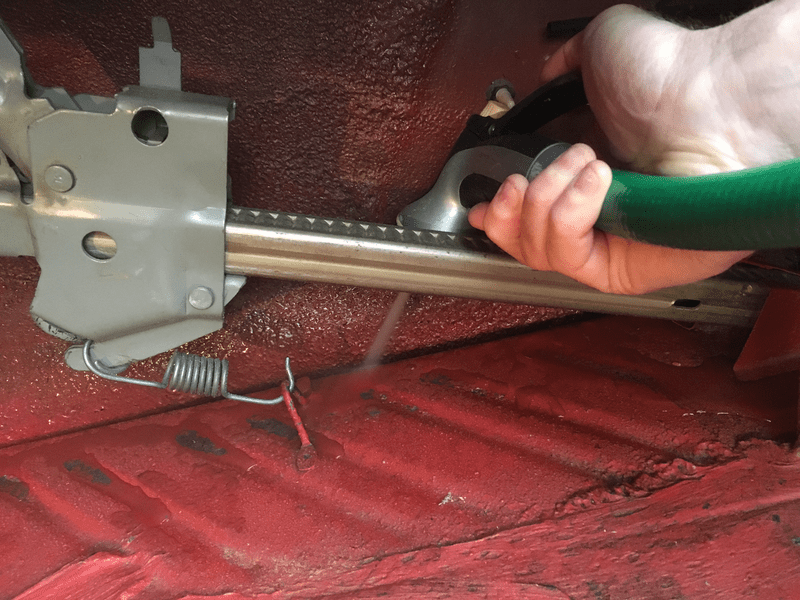

I used a piece of wire to scrape out the dirt from the "V" at the bottom of the quarter.

Then I flushed it out with water to get the last of the dirt, followed by acetone to remove the water.

I let it dry overnight, then sprayed Rustoleum Rust Reformer on all the rust I could get to. I sprayed it in through the holes in the quarter panel, and down past the trunk extension panels from inside the trunk. I also sprayed the inside of the rocker through the hole. I'm sure I missed a few spots, but I'm going to do my best to keep water out of there anyway by completely filling those areas with filler that I'm going to make using West Marine 2-part epoxy and colloidal silicon filler.

I found a one-inch rotten spot on the wheel house, barely visible until I started poking at it.

Looking in the new hole, I could see the rocker is rusting from the inside out--as many FABO'ers could have told me.

I also found I could see the quarter panel rust from the inside of the trunk, once I knew where to look--right where the wheelhouse, trunk extension, and quarter skin meet, on both sides of the car. Here's the left side.

And on the right side.

I used a piece of wire to scrape out the dirt from the "V" at the bottom of the quarter.

Then I flushed it out with water to get the last of the dirt, followed by acetone to remove the water.

I let it dry overnight, then sprayed Rustoleum Rust Reformer on all the rust I could get to. I sprayed it in through the holes in the quarter panel, and down past the trunk extension panels from inside the trunk. I also sprayed the inside of the rocker through the hole. I'm sure I missed a few spots, but I'm going to do my best to keep water out of there anyway by completely filling those areas with filler that I'm going to make using West Marine 2-part epoxy and colloidal silicon filler.

rich006

Learning as I go

You mix the hardener and the resin in a mixing tub, then you stir in filler until it's the consistency of toothpaste, then you put it in the tubes and use a standard caulk gun to apply it. They say you can use a dowel to push dried epoxy out of the tubes and reuse them. The pumps are designed so you get the right proportions of resin and hardener if you use the same number of pumps of both.

Ben Drinkin

Hey bartender!

Interesting. I'll be watching..View attachment 1715007830

You mix the hardener and the resin in a mixing tub, then you stir in filler until it's the consistency of toothpaste, then you put it in the tubes and use a standard caulk gun to apply it. They say you can use a dowel to push dried epoxy out of the tubes and reuse them. The pumps are designed so you get the right proportions of resin and hardener if you use the same number of pumps of both.

GeorgeH

Well-Known Member

Have used west system products ...umm.. for boats. The metal will continue to rust underneath it.

rich006

Learning as I go

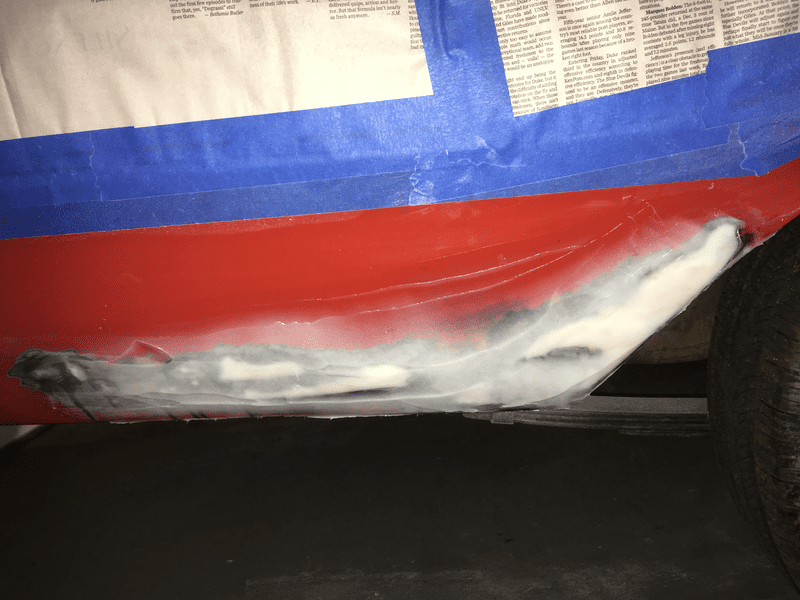

I used a caulk gun to inject the West System filler into the cavity through all the holes that were big enough, until it started oozing out the smaller holes, then I smoothed it with a spreader. I went through about 4 tubes of it; each tube was 10 squirts of resin, 10 squirts of hardener, and about 3 cups of colloidal silica filler, to make it the consistency of toothpaste. They say you can reuse the tubes. I did that once but it was a lot easier to use a new tube every time. The 206 hardener gave me enough working time (~90 minutes) to repeat the mixing process several times while the applied filler was still workable.

adamm

Well-Known Member

I used a caulk gun to inject the West System filler into the cavity through all the holes that were big enough, until it started oozing out the smaller holes, then I smoothed it with a spreader. I went through about 4 tubes of it; each tube was 10 squirts of resin, 10 squirts of hardener, and about 3 cups of colloidal silica filler, to make it the consistency of toothpaste. They say you can reuse the tubes. I did that once but it was a lot easier to use a new tube every time. The 206 hardener gave me enough working time (~90 minutes) to repeat the mixing process several times while the applied filler was still workable.

View attachment 1715008500

View attachment 1715008509

I'll be interested to see how this develops for you. Thanks for sharing.

rich006

Learning as I go

Ha, me too.I'll be interested to see how this develops for you.

rich006

Learning as I go

I ground off the epoxy blobs with a flap wheel, then wiped off the dust with acetone. I mixed up another batch of the same filler and applied it with a regular spreader to fill the low spots.

For color matching, I found a nearby Finishmaster location that can mix up a single-stage paint in E5. I get 8 oz of paint plus the additives, which will make me about a pint all mixed up, for $68. They are calling it Salsa Red, so I'm afraid they may be talking about a new color called PE5 Salsa Red Pearl, but maybe it's right if they leave out the "pearl" additive? I'll check on that before I buy.

I also need to pick up a finer colloidal silica additive to finish the shaping.

For color matching, I found a nearby Finishmaster location that can mix up a single-stage paint in E5. I get 8 oz of paint plus the additives, which will make me about a pint all mixed up, for $68. They are calling it Salsa Red, so I'm afraid they may be talking about a new color called PE5 Salsa Red Pearl, but maybe it's right if they leave out the "pearl" additive? I'll check on that before I buy.

I also need to pick up a finer colloidal silica additive to finish the shaping.

v8fish

Well-Known Member

So here's my question : I see you filled from inside did you fill up to trunk pan or how far above the rust lone did you fill?

adamm

Well-Known Member

How much does that product weigh once it dries?

rich006

Learning as I go

So here's my question : I see you filled from inside did you fill up to trunk pan or how far above the rust lone did you fill?

I didn't fill it from inside the trunk. I just used the caulk gun to squirt it in through the rust holes. I wanted to start from the bottom and work my way up, to make sure not to leave an empty cavity at the bottom. You have to look to see it from inside the trunk. Here's a shot looking downward at the edge of the trunk. The black is rust reformer and the white is the filler.

I could add a little more from the top, but I don't think it would do any good. It looks like all the rust started from the seam where 3 panels come together: the trunk dropoff, the inner quarter, and the skin. That seam was open to water/dirt/salt coming in from the outside. I believe if I seal that from the outside, then the inside will stay pretty dry from now on. The visible white blob in the picture below shows where that seam is.

One thing I don't get is how water is supposed to get out of the rear quarter if it gets in. The rocker panels have openings that look like they are supposed to be drains, but the quarter seems completely sealed. I guess drain holes there would do more harm than good? Maybe the pinch welds are supposed to be leaky enough to drain water out? I'm also not sure why the inner quarter needs the 2-inch opening that has to be sealed by a plastic plug. Anyway, I no longer have that opening because that whole area is filled in.

How much does that product weigh once it dries?

The resin weighs about the same as water, say 8 lbs/gal. But the mix is mostly silica, which weighs basically nothing. I bet the filler I added weighs less than the scale and dirt I cleaned out.

GeorgeH

Well-Known Member

I ground off the epoxy blobs with a flap wheel, then wiped off the dust with acetone. I mixed up another batch of the same filler and applied it with a regular spreader to fill the low spots.

View attachment 1715009385

For color matching, I found a nearby Finishmaster location that can mix up a single-stage paint in E5. I get 8 oz of paint plus the additives, which will make me about a pint all mixed up, for $68. They are calling it Salsa Red, so I'm afraid they may be talking about a new color called PE5 Salsa Red Pearl, but maybe it's right if they leave out the "pearl" additive? I'll check on that before I buy.

I also need to pick up a finer colloidal silica additive to finish the shaping.

Finishmaster should be able to computer match it with the camera. It would likely be far more accurate then mixing from a formula for that.

rich006

Learning as I go

Finishmaster should be able to computer match it with the camera. It would likely be far more accurate then mixing from a formula for that.

That makes sense. I'll bring in the gas cap.

-