Probably going the have a few questions.

To start

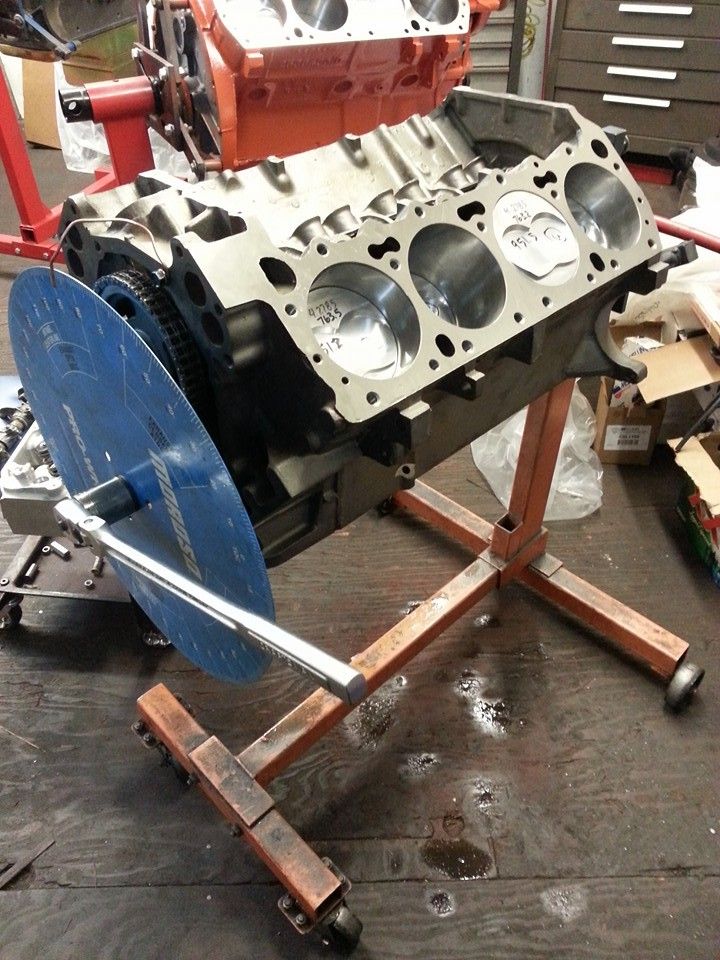

70 383

How do I know what to set my initial and all in timing too? Comp xe 274H cam. I know most say 20 and 36 all in.

Also I took a bunch off the block to get 0-5 thousand piston to deck height. Will stock pushrods still work? Running stock rockers.

Thanks guys

To start

70 383

How do I know what to set my initial and all in timing too? Comp xe 274H cam. I know most say 20 and 36 all in.

Also I took a bunch off the block to get 0-5 thousand piston to deck height. Will stock pushrods still work? Running stock rockers.

Thanks guys