turbodart68

Well-Known Member

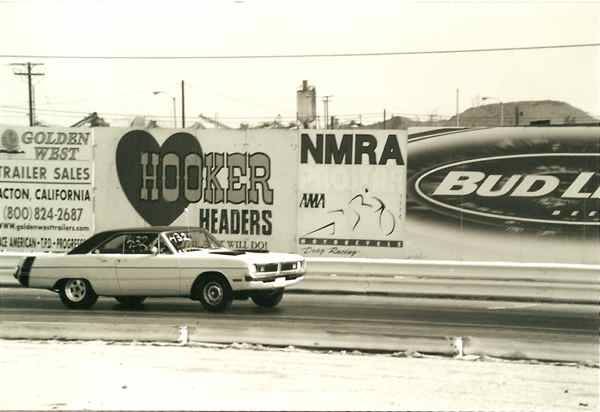

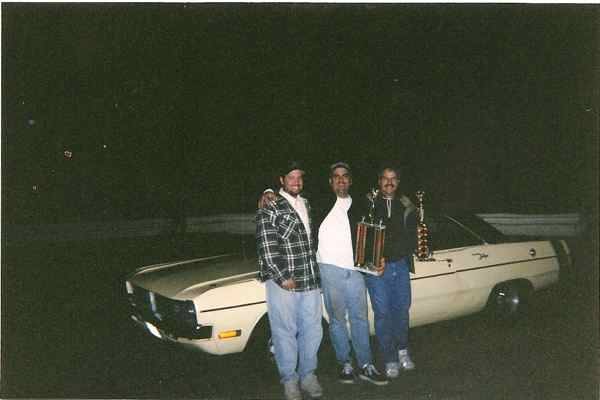

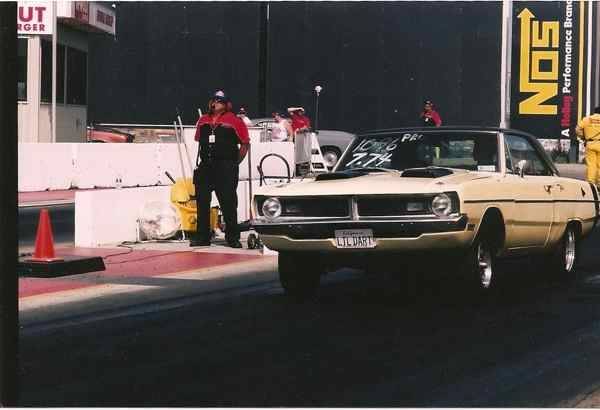

Hey everyone, among other things I have this Swinger I bought in 1999. Originally I put my spare motor and trans from my 68 Dart into it and ran it in some bracket races. It had several various 360s in it along the way. The last motor was .040 with JE zero deck flat tops, ported J heads (self ported, my first set) stock rods, stock crank. It also had a Torker II 340 with a 750 DP holley. Exhaust consisted of 1 5/8 cheapy headers and 2.5 inch exhaust, mandrel bent and a homemade x-pipe (more of a chamber) and 2 chamber Flowmasters. The trans is a 904 built by Protrans with low gear set and otherwise stock, 10 inch continental converter (3300 stall). The rear is an 8.75 with 4.56 gears and a light weight spool. This car weighed 3440 with me in it and ran a best of 11.68@116 mph on the motor at Sacremento Raceway (good air). On a 150 shot of nitrous it ran 10.92@128 at Las Vegas at the 2003 MATS durig the midnight madness on Saturday night. This car was very consistent and resulted in good results bracket racing. Unfortunately it had some pretty serious rust issues from the vinyl top. I bought this car from a parking lot with a sign in it. Best buy ever @ 600 bucks. It originally had a 318 in it and ran pretty good, unfortunately it died a ridiculous death by nitrous. I have tons of stories in this car and am very attached to it. Sooooo when the car spun a rod bearing at Irwindale, I thought it deserved a full resto.