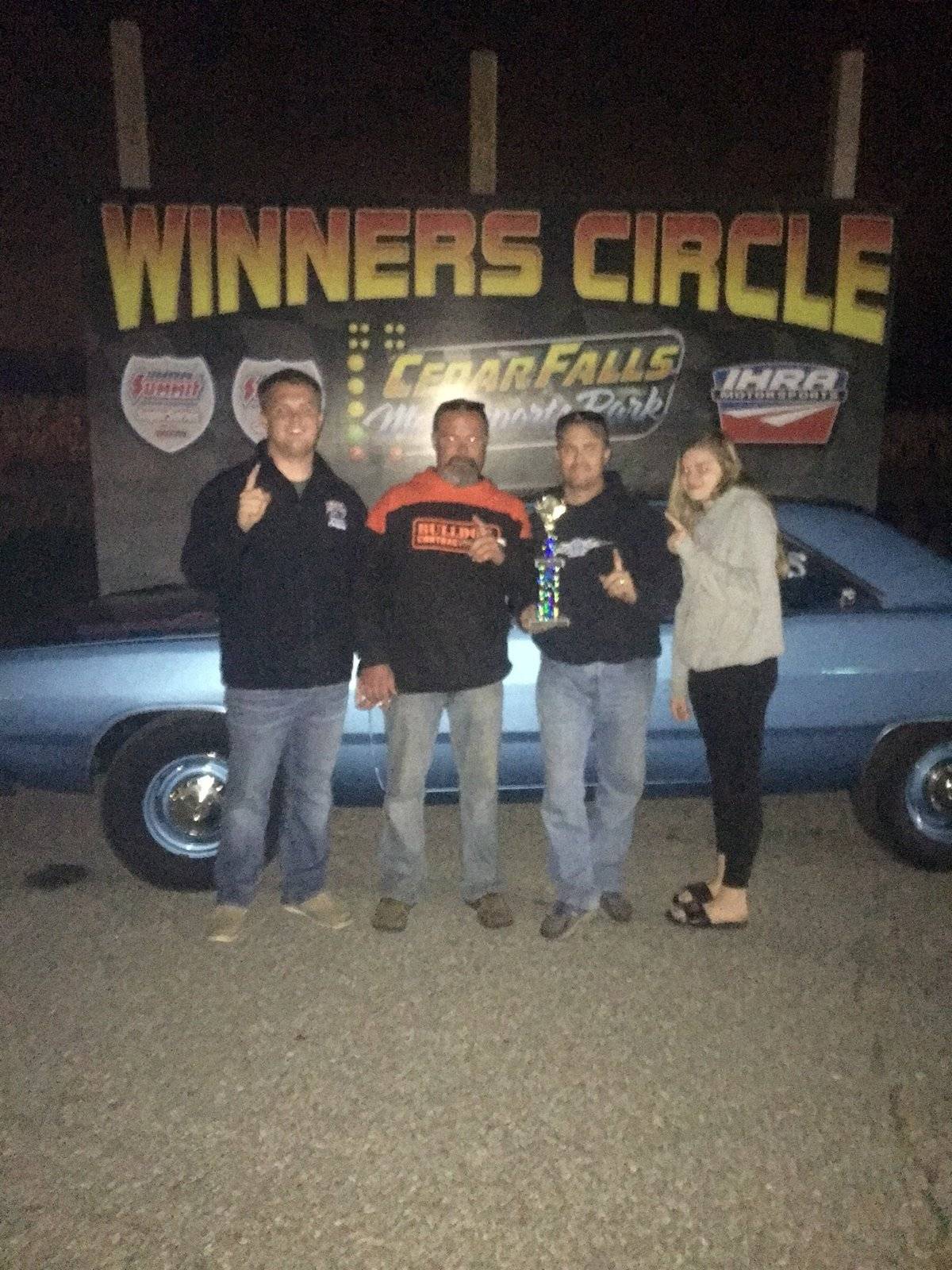

Made it to the track with new MP 557/296 solid cam in my 340, advanced 4 degrees when I degreed it in, stock replacement pistons, X heads with some bowl clean up. Last summer at the track with the old cam, MP 508/280 solid, 4.10 rear gear and 27 inch tires, it ran 13.40's @ 102 with full exhaust, just like I drive it on the street. It usually picks up .3-.4 and 104-105 mph with open headers. The new cam and 4.56 gear with full exhaust it ran 13.55 @ only 98mph? Trapping at little over 6000 rpm. I also put an A/F meter in to help with getting the jetting right, that showed 12.5-13.02 through all the runs. Is it possible I am just reving right through the power and I need a 4.10 or 3.91 gear? It also ran the same 60 foot as the old cam. As a side note, I won the trophy class, made me feel a little better.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Too much gear?

- Thread starter gtsdude

- Start date

-

4mulas

Fixem'up

What were the atmosperic conditions on each day. That could affect the performance.

But maybe the 4.56 is a bit steep too, imo.

But maybe the 4.56 is a bit steep too, imo.

With the cam advanced 4 degree, it may not want to be rev'd that high.......or maybe it wants more. don't know.

How is your fuel system? New cam maybe taxing your current setup? See where your o2s are heading at the top end of the track.

How is your fuel system? New cam maybe taxing your current setup? See where your o2s are heading at the top end of the track.

I recorded the tach and A/F gauge with my phone on a run. At 6000 in 3rd gear it showed 12.5. My son had a similar thing happen with a 340 aspen, broke the 355 rear and all we had was a 486. Put a 28.5 or so tire on it. Ran the same mph as I did in the 1/4. That one had a smaller cam also advanced 4 degrees. Sold it before we could take it out with a higher gear.

Last edited:

Tire seems tall enough. Did you put matching valve springs in?

Did you change your dist or set it at a different timing?

something sure kill 4 mile per hour! Maybe your cams hp curve falls sharply after max hp.........If so, a gear change is mandatory or take the 4 degrees advance back out of it.??????

something sure kill 4 mile per hour! Maybe your cams hp curve falls sharply after max hp.........If so, a gear change is mandatory or take the 4 degrees advance back out of it.??????

I run the MP 296/.557 in my 360, Eddy heads, M1 intake, 750DP Holley, in my Barracuda, 4.56 gears, 28x9 Hoosier slicks I trapped 11.14 at 120.27mph, don't remember what the RPM was.

Crunching numbers says I crossed the line at 6584 rpm.

Granted, I got more cylinder head on my combination; I don't think it would account for a 22mph difference, plus the fact you lost 4 mph relative to your old .508/280 combination.

As a guess of what to do, up your shift point.......the .557 is gonna peak power higher in the rpm range, get up there and use it.

Crunching numbers says I crossed the line at 6584 rpm.

Granted, I got more cylinder head on my combination; I don't think it would account for a 22mph difference, plus the fact you lost 4 mph relative to your old .508/280 combination.

As a guess of what to do, up your shift point.......the .557 is gonna peak power higher in the rpm range, get up there and use it.

roccodart440

Well-Known Member

- Joined

- Apr 19, 2010

- Messages

- 6,801

- Reaction score

- 3,578

What were the atmosperic conditions on each day. That could affect the performance.

But maybe the 4.56 is a bit steep too, imo.

It's only trapping 6,000 even with that Godzilla cam in it. He may need more gear, not less. It relaly needs to be run on a dyno to know where it's running out of wind.

What carb is on it? Maybe those heads are the issue. Something isn't adding up with that that timeslip.

X heads that were cleaned up in the bowls, port matched as well. Has a 750 Holley DP with pro form main body. 3/8 fuel line, with black Holley pump and regulator too. Pump is 10 years old, you would think it would lean out on A/F gauge if it was not keeping up?

roccodart440

Well-Known Member

- Joined

- Apr 19, 2010

- Messages

- 6,801

- Reaction score

- 3,578

Yes, it isn't the pump or line. Your A/F gauge would show it.

My guess is too small of a carb, especially sitting on those heads.

My guess is too small of a carb, especially sitting on those heads.

Did the intake get cocked a little when install after cam replacement? Easy to check, lay a straightedge across the carb and then measure down to each valve cover.

Maybe this cam just want a complete different combo!

Maybe this cam just want a complete different combo!

perfacar

Well-Known Member

did you open the headers?? with bigger cam, prob bottled up, with exhaust closed. also, what ign system ?? just food for thought.27 inch tire, shifted at 6200, conditions were about the same.

It's only trapping 6,000 even with that Godzilla cam in it. He may need more gear, not less. It relaly needs to be run on a dyno to know where it's running out of wind.

What carb is on it? Maybe those heads are the issue. Something isn't adding up with that that timeslip.

To your comment of more gear may be needed, I ran 11.14 at 118.45 with 4.88's in the back; the rest of the combination was the same..........I picked up mph by taking gear out of the car when I went with 4.56's.

A thought just came to mind.......did your throttle cable move in it's clamp? Happened to me, one time trial I went 11.64 at 116.6mph, 1.86 60 ft, next I went 11.88 at 107.2mph, 1.56 60 ft.........looking the car over found the throttle cable was loose in its clamp.

Ran it with exhaust on for the class we ran, I should have tried it uncorked, may need to do a test and tune. I did check throttle right after I swapped cams, but I'd did have carb off again, I will check that again. FBO ignition box and coil. MP adjustable dizzy

Ok going out on a limb, and a long post!

Stock j heads flow around 200 cfm@ at a max of 500 lift. cut a 2.02 in and a good valve job and it will flow in the 230s to 240@500 lift (600 lift the flow slows down(225 cfm))

I took a set of j head just like yours and did all kinds of porting, find water jacket, fill in with epoxy, ground some more. Filled in the floor, shaped the Short Side Radius(SSR) a hundred difference was.

Even got it to flow 240 by .300 lift and 270 by .500 lift! The problem, COULD NOT GET IT TO FLOW PAST .500 LIFT. Every time it would crash in flow, and sometime, the turbulence was so bad that it sounded like i was pouring water into the port. I finally fixed the problem! it was in the combustion chamber! USED CLAY TO EMULATE A CLOSED CHAMBER AND WOLA!!!! IT FLOWED TO .700 LIFT. You can't weld up a combustion chamber on a cast iron head. Finally did get a shape in the combustion chamber that would hold on past .500 but was Alway Noise!(these head were going to be for my 408!)

Ended up buying some 2.02 RHS head from brian at IMM (cast iron head with a closed chamber design) and of course, had to give them a quick flow before i put them on.

Flowed more at .500, .550 and .600 and held the cfm to .700!!! but what made me know i had made a good move was how smooth the air sounded going thru the port.(my velosite prob said so too!) Even at .700 lift.

Now Why did i tell you all of this? Your port might be going turbulent above .500 lift! (old cam never saw it)

Flow may be slowing down above .500 lift causing the head to produce less flow not more and acting like a smaller cam, not bigger??????

Like i said, going out on a limb......................

A couple more thoughts.

You probably could use a bigger carb, BUT the Larger cam and Same carb, AT THE VERY LEAST, would keep the same mph not loose 4!

I higher stall may get you a better ET but, both cams 60' similar so, you're making similar HP at 3000 rpm.

Stock j heads flow around 200 cfm@ at a max of 500 lift. cut a 2.02 in and a good valve job and it will flow in the 230s to 240@500 lift (600 lift the flow slows down(225 cfm))

I took a set of j head just like yours and did all kinds of porting, find water jacket, fill in with epoxy, ground some more. Filled in the floor, shaped the Short Side Radius(SSR) a hundred difference was.

Even got it to flow 240 by .300 lift and 270 by .500 lift! The problem, COULD NOT GET IT TO FLOW PAST .500 LIFT. Every time it would crash in flow, and sometime, the turbulence was so bad that it sounded like i was pouring water into the port. I finally fixed the problem! it was in the combustion chamber! USED CLAY TO EMULATE A CLOSED CHAMBER AND WOLA!!!! IT FLOWED TO .700 LIFT. You can't weld up a combustion chamber on a cast iron head. Finally did get a shape in the combustion chamber that would hold on past .500 but was Alway Noise!(these head were going to be for my 408!)

Ended up buying some 2.02 RHS head from brian at IMM (cast iron head with a closed chamber design) and of course, had to give them a quick flow before i put them on.

Flowed more at .500, .550 and .600 and held the cfm to .700!!! but what made me know i had made a good move was how smooth the air sounded going thru the port.(my velosite prob said so too!) Even at .700 lift.

Now Why did i tell you all of this? Your port might be going turbulent above .500 lift! (old cam never saw it)

Flow may be slowing down above .500 lift causing the head to produce less flow not more and acting like a smaller cam, not bigger??????

Like i said, going out on a limb......................

A couple more thoughts.

You probably could use a bigger carb, BUT the Larger cam and Same carb, AT THE VERY LEAST, would keep the same mph not loose 4!

I higher stall may get you a better ET but, both cams 60' similar so, you're making similar HP at 3000 rpm.

Maybe the combo of corked up exhaust and small carb, new cam just didn't like it? Tail pipes used to choke down the smaller cam, probably worse with new cam

My opinion, carb is not too small..........what size primaries on headers, collector, and remaining exhaust system? To have hurt that much, you would have had to shrink the system..........as an example, I run 1 5/8 primary tubes, 2 1/2 inch collectors, 2 1/2 inch pipe to mufflers with 2 1/2 inch in and out. If your exhaust system is equal to or larger then that at any point, exhaust is NOT your problem.

I know this is a some what silly question........did you make sure your carb went fully open when you stood on the gas pedal? Goes along with did the cable slip in the clamp.

Exhaust is 2.5 to muffler, choke

Masters, factory tail pipes on it. 2 1/4 or smaller in the bends. I knew it killed the old cam a little, didn't think it would kill this on that much. I am going to check the throttle again to make sure.

Masters, factory tail pipes on it. 2 1/4 or smaller in the bends. I knew it killed the old cam a little, didn't think it would kill this on that much. I am going to check the throttle again to make sure.

Ok going out on a limb, and a long post!

Stock j heads flow around 200 cfm@ at a max of 500 lift. cut a 2.02 in and a good valve job and it will flow in the 230s to 240@500 lift (600 lift the flow slows down(225 cfm))

I took a set of j head just like yours and did all kinds of porting, find water jacket, fill in with epoxy, ground some more. Filled in the floor, shaped the Short Side Radius(SSR) a hundred difference was.

Even got it to flow 240 by .300 lift and 270 by .500 lift! The problem, COULD NOT GET IT TO FLOW PAST .500 LIFT. Every time it would crash in flow, and sometime, the turbulence was so bad that it sounded like i was pouring water into the port. I finally fixed the problem! it was in the combustion chamber! USED CLAY TO EMULATE A CLOSED CHAMBER AND WOLA!!!! IT FLOWED TO .700 LIFT. You can't weld up a combustion chamber on a cast iron head. Finally did get a shape in the combustion chamber that would hold on past .500 but was Alway Noise!(these head were going to be for my 408!)

Ended up buying some 2.02 RHS head from brian at IMM (cast iron head with a closed chamber design) and of course, had to give them a quick flow before i put them on.

Flowed more at .500, .550 and .600 and held the cfm to .700!!! but what made me know i had made a good move was how smooth the air sounded going thru the port.(my velosite prob said so too!) Even at .700 lift.

Now Why did i tell you all of this? Your port might be going turbulent above .500 lift! (old cam never saw it)

Flow may be slowing down above .500 lift causing the head to produce less flow not more and acting like a smaller cam, not bigger??????

Like i said, going out on a limb......................

A couple more thoughts.

You probably could use a bigger carb, BUT the Larger cam and Same carb, AT THE VERY LEAST, would keep the same mph not loose 4!

I higher stall may get you a better ET but, both cams 60' similar so, you're making similar HP at 3000 rpm.

Interesting hypothesis......spelled out like that it makes sense; how would you prove it?

-