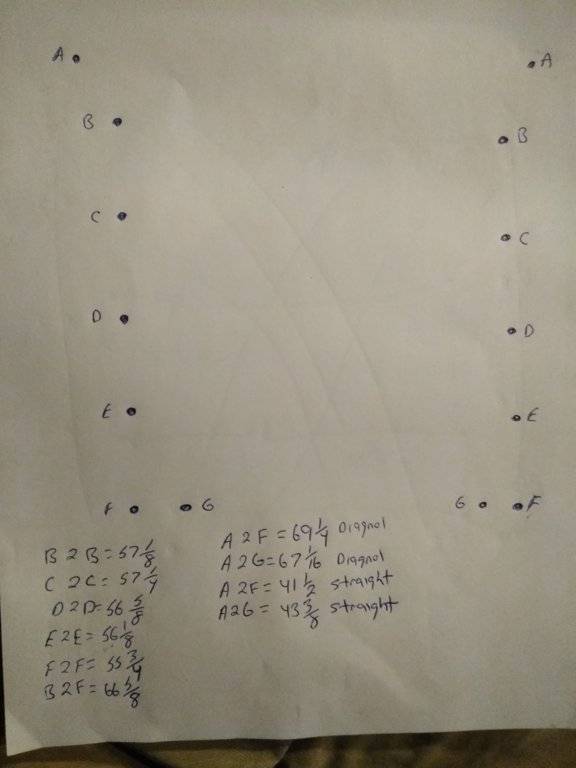

Actually these were taken from a 74 today but I am certain that they will be the same from sometime before 71 on up till at least 74. Doing a google search gave me no help so I hope that these will help someone later on.

I am a bodyman, these are very accurate measurements and they werent taken from some random guy that haphazardly took a tape and sorta measured.

Any questions feel free to ask and assuming I see the question I will respond, if no response than I didnt see it and just send me a PM or whatever you now call it.

BTW this car was as square as any brand new car that rolls off the assy line today but bear in mind there is alot more play with the sheetmetal cause they used J-clips on a slot

I am a bodyman, these are very accurate measurements and they werent taken from some random guy that haphazardly took a tape and sorta measured.

Any questions feel free to ask and assuming I see the question I will respond, if no response than I didnt see it and just send me a PM or whatever you now call it.

BTW this car was as square as any brand new car that rolls off the assy line today but bear in mind there is alot more play with the sheetmetal cause they used J-clips on a slot