diymirage

HP@idle > hondaHP@redline

kinda jumping the gun here but it looks like I might have an issue wit my 360 which warrants a rebuild

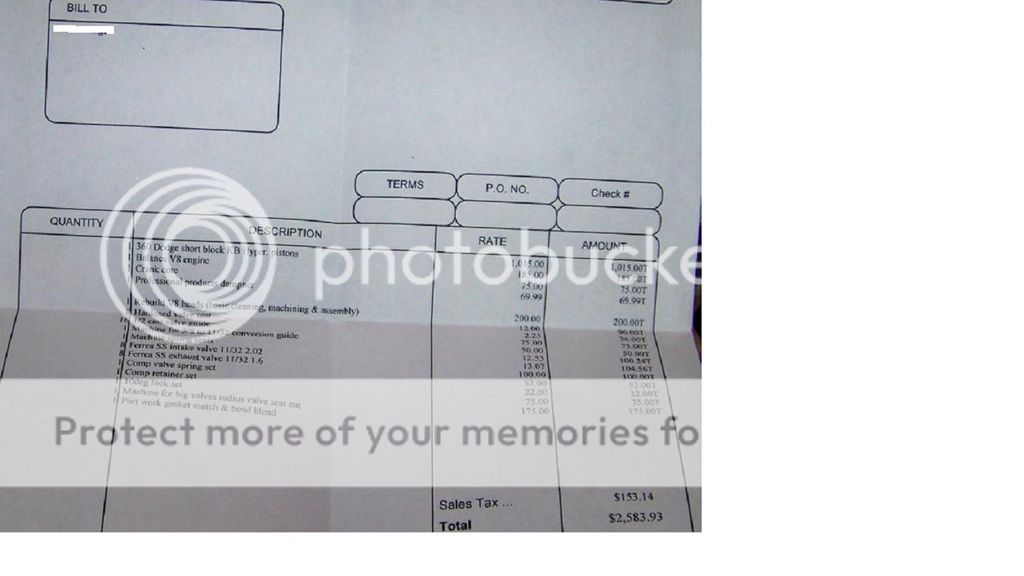

I called a local machine shop and they quoted me around $2500.00

after we talked a bit about what is on the engine right now it came down to $1900.00

(main reason being they serviced the heads last winter, the timing set is new and so is the cam and lifter set up)

so this should include machine work on the block, crank and rods (if needed)

new pistons (9.5 to 1) and assembly into a long block

does this sound fair?

and what should I expect to add to the price tag if I have them build it into a 408 stroker?

I called a local machine shop and they quoted me around $2500.00

after we talked a bit about what is on the engine right now it came down to $1900.00

(main reason being they serviced the heads last winter, the timing set is new and so is the cam and lifter set up)

so this should include machine work on the block, crank and rods (if needed)

new pistons (9.5 to 1) and assembly into a long block

does this sound fair?

and what should I expect to add to the price tag if I have them build it into a 408 stroker?