I do have a question about the factory settings. I remember when I set up the rearend I measured the angle of the spring perches on the stock axle and they were at 5* nose up. I have read a lot of posts where other people took * measurements of their factory installed perches and they were all around 4* or 5* nose up from the factory. This has me puzzled. Why were they set like this from the factory?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which way should I go with pinion angle ??????????????????????

- Thread starter duster360

- Start date

-

adriver

Blazing Apostle

Forget about your perches.

You are confusing me.

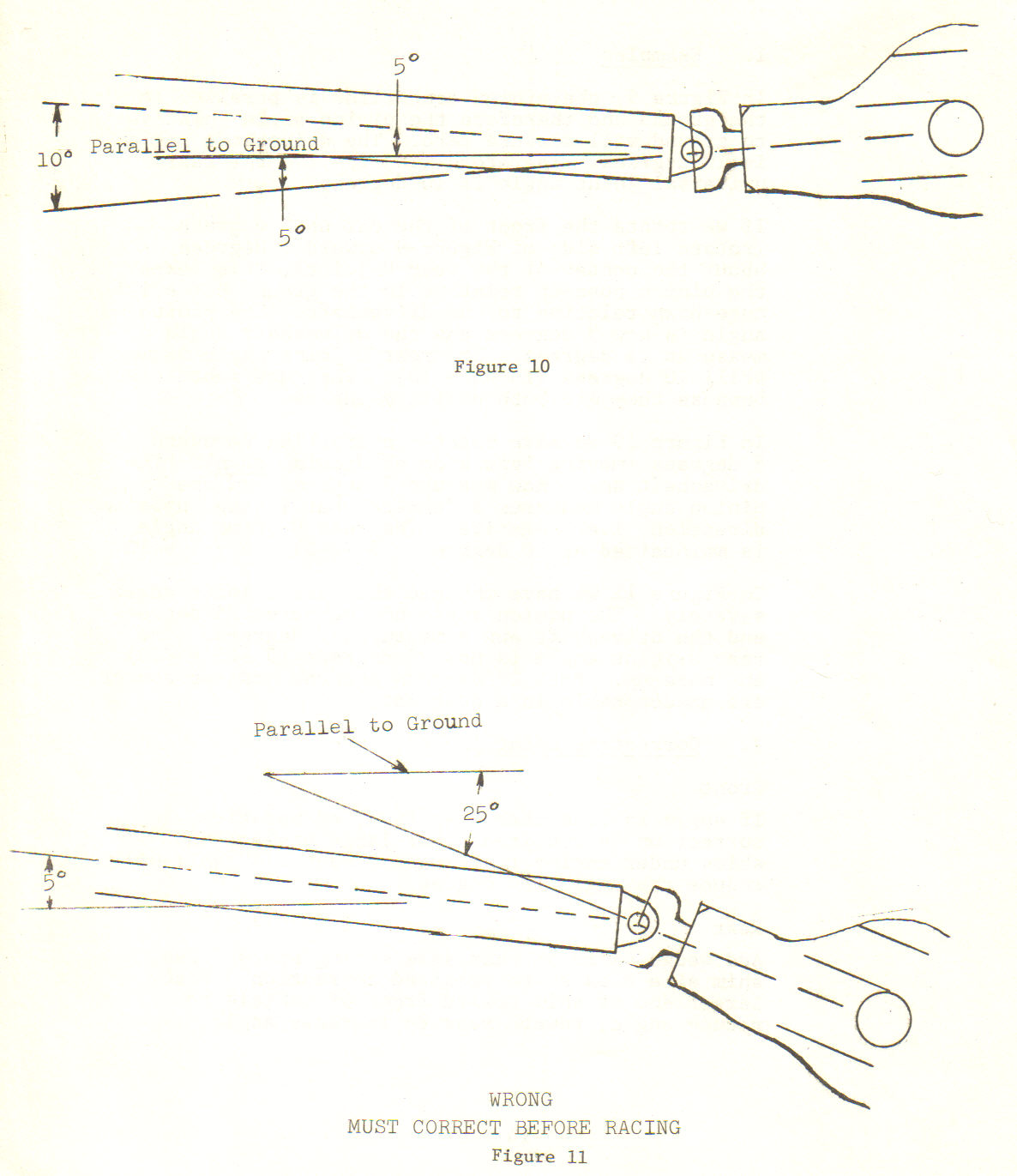

Measure at the yolk like this.

You punkin should be pointing down. The oposite of the trans tail shaft.

Like a "z" sort of.

Picture them oposite. The wobble "cancels" each other out.

The variable is the punkin nose goes up under torque.

That's what the differnent settings, because of different uses.

A drag car is different than a street car cause it is always wanting to wind up.

A lot.

Chrysler had dual u joints in some Imperials to give the shaft a cv effect.

"Constant velocity".

Someone correct me if I've gotten anything wrong.

Like you wont! LOL

You are confusing me.

Measure at the yolk like this.

You punkin should be pointing down. The oposite of the trans tail shaft.

Like a "z" sort of.

Picture them oposite. The wobble "cancels" each other out.

The variable is the punkin nose goes up under torque.

That's what the differnent settings, because of different uses.

A drag car is different than a street car cause it is always wanting to wind up.

A lot.

Chrysler had dual u joints in some Imperials to give the shaft a cv effect.

"Constant velocity".

Someone correct me if I've gotten anything wrong.

Like you wont! LOL

Attachments

I got another driveshaft today. It will need to be shortened a little but I had just enough room to wiggle it in to get a good visual of what everyone is saying. I got it now. Since the trans is at 0* and the rearend is 4* nose up, I would have to use way too much shim to get it turned to where it needs to be. So. I am going to pull the rearend and cut the perches off and have some new ones welded on at the correct angle.

Now here is the big question. For a street car that will probably never exceed 400hp, how much pinion angle will I need? It will be fairly simple since the trans is at 0*. I know it will need to be anywhere from 2*-7* nose down at the pinion. 2* seems like not enough, but 7* seems too much. To me 4*-5* nose down seems close. Any more than that and I don't think the axle would ever wind up enough to use 7*. What do you think?

Now here is the big question. For a street car that will probably never exceed 400hp, how much pinion angle will I need? It will be fairly simple since the trans is at 0*. I know it will need to be anywhere from 2*-7* nose down at the pinion. 2* seems like not enough, but 7* seems too much. To me 4*-5* nose down seems close. Any more than that and I don't think the axle would ever wind up enough to use 7*. What do you think?

I'd do 3* down.

moparlover

Well-Known Member

because where the axle connects to the spring is not level with the ground ;)

this is what Cass sent me via email when setting up my dana60 (Cass = doctor diff)

"A stock A-body spec Dana housing is 52 5/8" wide with the driver's side tube 1 3/8" longer than the passenger's side.

If you install my offset spring hanger/shackle kit, spring perches will be 42" on center. Pinion points upward 5 degrees when the perches are level with the ground."

the 42" dimension is because i have the 1/2" offset kit. normally that is 43 i think

but the pinion points upward 5 degrees when perches are level with the ground

that's the info for welding the perches on. nose up 5 degrees when perches level with the floor.

once you mount the axle on the springs it will be where it's supposed to be, unless you have some weird springs.

this is what Cass sent me via email when setting up my dana60 (Cass = doctor diff)

"A stock A-body spec Dana housing is 52 5/8" wide with the driver's side tube 1 3/8" longer than the passenger's side.

If you install my offset spring hanger/shackle kit, spring perches will be 42" on center. Pinion points upward 5 degrees when the perches are level with the ground."

the 42" dimension is because i have the 1/2" offset kit. normally that is 43 i think

but the pinion points upward 5 degrees when perches are level with the ground

that's the info for welding the perches on. nose up 5 degrees when perches level with the floor.

once you mount the axle on the springs it will be where it's supposed to be, unless you have some weird springs.

moparlover

Well-Known Member

Supershafts

Well-Known Member

Set it at 4 degrees down from the shaft, so when it is under power it is at 0.0

put the housing in the car slightly tighten the u-bolts, put it on a drive on lift, 4 ramps, whatever and then adjust it to the 4 degrees down from the shaft, tack the percehes and then weld them, then check the housing is still straight and hasn't moved, which they usually do.

.

put the housing in the car slightly tighten the u-bolts, put it on a drive on lift, 4 ramps, whatever and then adjust it to the 4 degrees down from the shaft, tack the percehes and then weld them, then check the housing is still straight and hasn't moved, which they usually do.

.

mprdrgrcr

Active Member

- Joined

- Sep 3, 2008

- Messages

- 30

- Reaction score

- 2

I have to comment on this one. Pinion angle is a relationship between the driveshaft and the rear axle, period. The driveshaft has be in the car to check pinion angle.All these references to the ground are confusing things. You could check pinion angle with the car standing on the back bumper if the suspension was loaded. It doesn't care where the ground is.

You need to load the suspension as the car would be normally used. Check the angle of the driveshaft to the pinion. 2-3 degrees nose down for a street car is fine. I've seen 10 or more on drag cars. The angle from the driveshaft to the transmission ideally is 2-3 down, but in a stock bodied/transtunnel car you can,t move the trans up or down much to adjust this.

You need to load the suspension as the car would be normally used. Check the angle of the driveshaft to the pinion. 2-3 degrees nose down for a street car is fine. I've seen 10 or more on drag cars. The angle from the driveshaft to the transmission ideally is 2-3 down, but in a stock bodied/transtunnel car you can,t move the trans up or down much to adjust this.

72ScampTramp

Scamp Tramp

Try this tech link from moparts http://www.moparts.org/Tech/Archive/axle/8.html

-