I know what to do, and can do the basic repairs but that's about it.

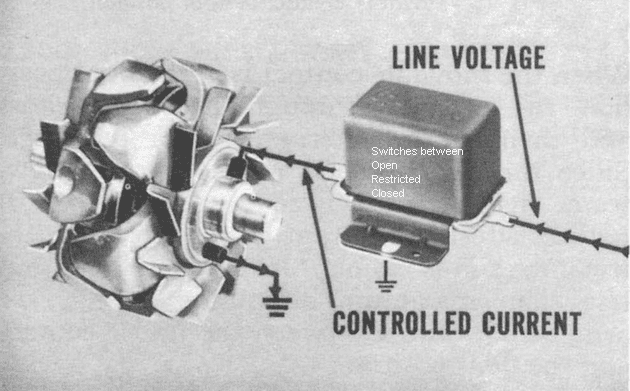

As we see in this Chrysler photo, electricity should be able to flow in from one slip ring and out the other.

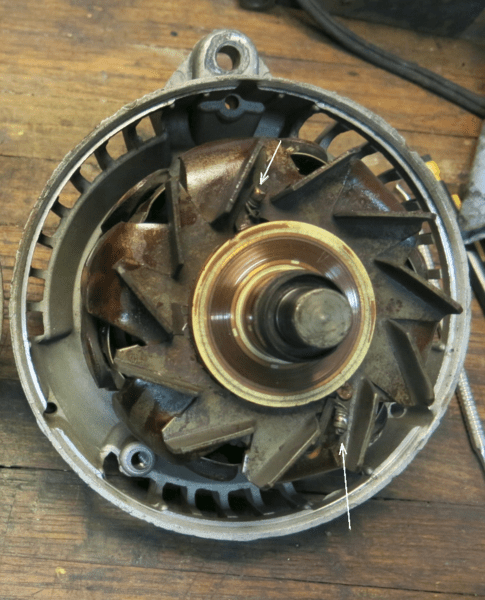

Here's the solder connections between the rotor windings and the each slip ring.

There are some shops that still rewind rotors. Most places unfortunately just install replacements from companies like Wai Wie.

Might look around locally to see if there's a place that will rewind.

A more sophisticated shop will try to match the rotor and the stator. The wire thickness, the number of windings, and maybe some other factors effect the performance. I don't know all of the tradeoffs but certainly the more wire in a rotor, the stronger the magnetic field can be.

PS. If your rotor has the grease shield, save it. A lot of rebuilt alternators dont have them.

That's it then. There is some sort of break in the windings. The rotor needs replacing or rewinding.The two rings are not connected, no continuity between them.

As we see in this Chrysler photo, electricity should be able to flow in from one slip ring and out the other.

Here's the solder connections between the rotor windings and the each slip ring.

There are some shops that still rewind rotors. Most places unfortunately just install replacements from companies like Wai Wie.

Might look around locally to see if there's a place that will rewind.

A more sophisticated shop will try to match the rotor and the stator. The wire thickness, the number of windings, and maybe some other factors effect the performance. I don't know all of the tradeoffs but certainly the more wire in a rotor, the stronger the magnetic field can be.

PS. If your rotor has the grease shield, save it. A lot of rebuilt alternators dont have them.