mike1965

Well-Known Member

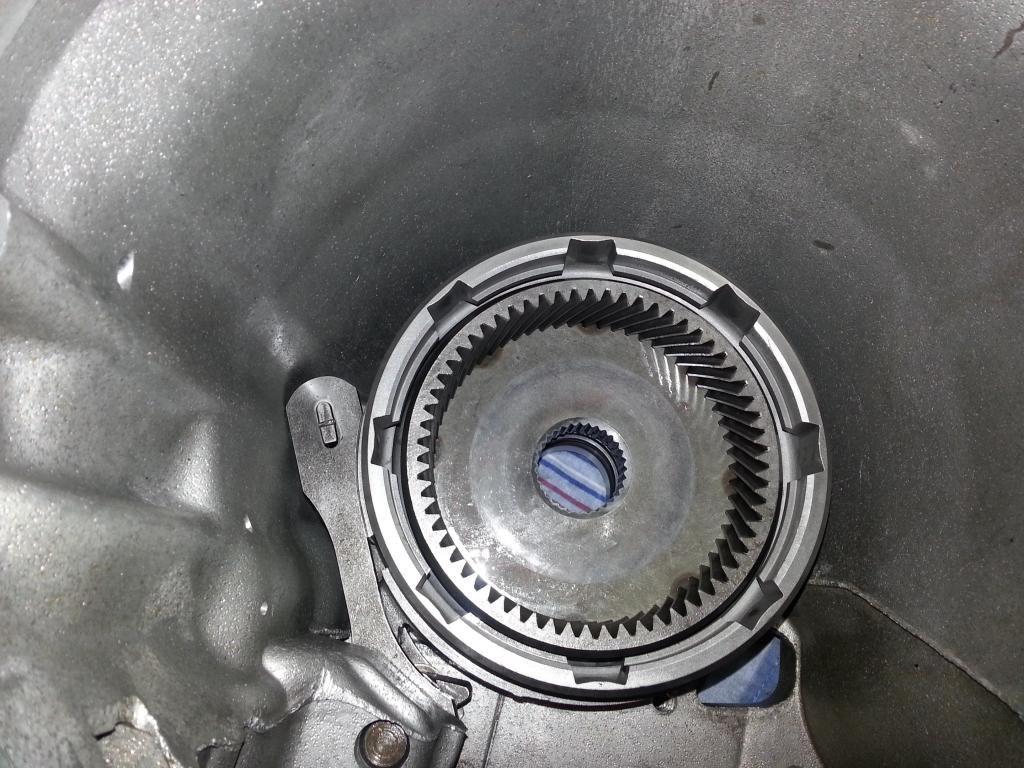

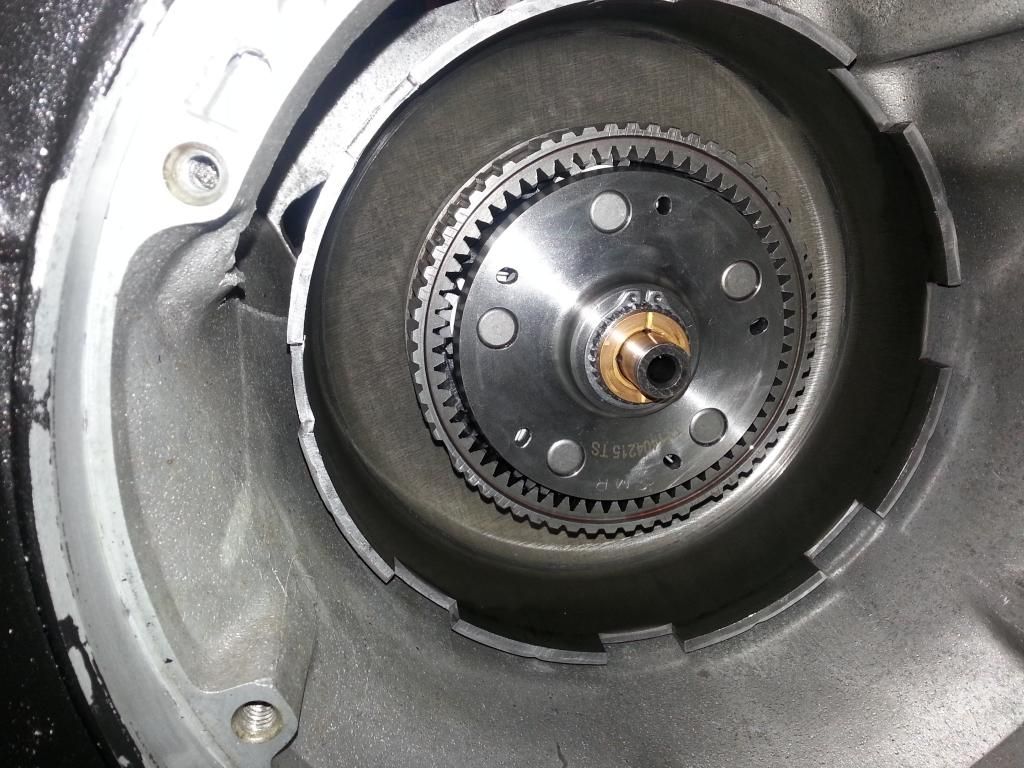

OK so have gathered all the parts to upgrade my 727 , here's a list of the upgraded parts I used to make this bullet proof hopefully .

- TCS 727 Sportsman Support Kit >> http://www.tcsproducts.com/products/product/556/

- A&A 727 6-Bolt Ultimate Sprag (1966-1989) >> http://www.aandatrans.com/Products/727-6-Bolt-Ultimate-Sprag-(1966-1989)__K22961US-6.aspx

- TCS Steel billet loaded drum with bigger piston

- A&A Steel 5 pinion planetary

- A&A 727 A518 A618 47RE 48RE Heavy Duty Band Strut

- A&A Super 2 1/4'' solid super band

We also plugged the vent hole in the pump and drilled a new vent hole near the back of the case above the sprag and drilled the case for the trans brake plug .

I machined the pump support for better oiling as recommended.

I disassembled the trans and cleaned it then started to put it back together I have only done to where the pictures stop , I have the pump placed in to the case with the paper gasket only and tomorrow I will measure my end play in the input shaft and I will set it to .020 - .025 after I have set that I will take the pump and put the rubber O ring on and install the pump permanently .

This is my first trans I have ever done I have built many engine's but tranny's just scared the hell outta me and I have to tell you if this thing works LOL I will do all my tranny's , I will post more pix as soon as I get more done on this.

Thanks for looking

- TCS 727 Sportsman Support Kit >> http://www.tcsproducts.com/products/product/556/

- A&A 727 6-Bolt Ultimate Sprag (1966-1989) >> http://www.aandatrans.com/Products/727-6-Bolt-Ultimate-Sprag-(1966-1989)__K22961US-6.aspx

- TCS Steel billet loaded drum with bigger piston

- A&A Steel 5 pinion planetary

- A&A 727 A518 A618 47RE 48RE Heavy Duty Band Strut

- A&A Super 2 1/4'' solid super band

We also plugged the vent hole in the pump and drilled a new vent hole near the back of the case above the sprag and drilled the case for the trans brake plug .

I machined the pump support for better oiling as recommended.

I disassembled the trans and cleaned it then started to put it back together I have only done to where the pictures stop , I have the pump placed in to the case with the paper gasket only and tomorrow I will measure my end play in the input shaft and I will set it to .020 - .025 after I have set that I will take the pump and put the rubber O ring on and install the pump permanently .

This is my first trans I have ever done I have built many engine's but tranny's just scared the hell outta me and I have to tell you if this thing works LOL I will do all my tranny's , I will post more pix as soon as I get more done on this.

Thanks for looking