Integral Valve Guide (Broken Boss) Repair Options

I thought the heads were really nice, especially compared to the OEM heads. Not sure how much attention from a die grinder these heads have had but I was impressed with how clean smooth the ports are.

One valve was slightly bent. Hard time coming out of the guide but other valves went in and out quite easily. The drill motor runout eyeball test indicated a good bit of wobble to that valve but other valves were seemingly fine.

It appears an OEM style seal was used, a slip over the guide type.

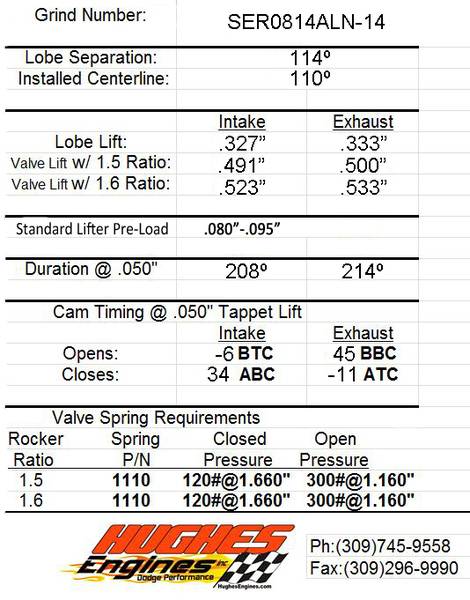

The motor is a roller cam, the heads came with Hughs 1110 Springs that should be good for .550 lift. As far as I know they are new(fish) springs. Don't think I will get that aggressive but would like to throw in a Cam that would compliment the truck and its uses (Towing, Hauling......Idle-5000) without having to get a tune right away. Haven't fixated on cams at this point until the heads are resolved but would love to hear suggestions as to what may suit me. Would like to stay with OEM pushrods and the OEM rockers right now

Hughes suggested this cam:

View attachment 1715470203

I thought the heads were really nice, especially compared to the OEM heads. Not sure how much attention from a die grinder these heads have had but I was impressed with how clean smooth the ports are.

One valve was slightly bent. Hard time coming out of the guide but other valves went in and out quite easily. The drill motor runout eyeball test indicated a good bit of wobble to that valve but other valves were seemingly fine.

It appears an OEM style seal was used, a slip over the guide type.

The motor is a roller cam, the heads came with Hughs 1110 Springs that should be good for .550 lift. As far as I know they are new(fish) springs. Don't think I will get that aggressive but would like to throw in a Cam that would compliment the truck and its uses (Towing, Hauling......Idle-5000) without having to get a tune right away. Haven't fixated on cams at this point until the heads are resolved but would love to hear suggestions as to what may suit me. Would like to stay with OEM pushrods and the OEM rockers right now

Hughes suggested this cam:

View attachment 1715470203