Base timing. Really ?

Whether the piston is 28* or 25* into the power stroke probably depends on the crank arm and rod and stroke ratios. Need to think about that or run some examples. Thats one of those little details that makes each engine a little different. But it really doesn't matter, the concept is the same.

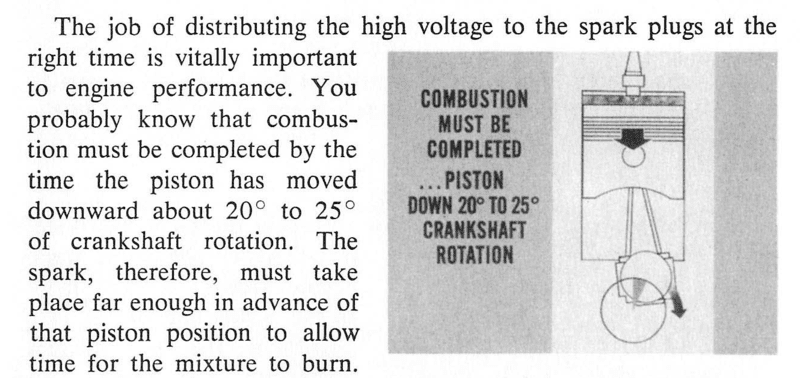

Reposting for those that may be not following why we're talking about pressure in the cylinder. It's all about maximizing leverage on the crank.

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because combustion efficiency increases with rpms. This means decreased burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opposite, poor - slow combustion at low rpms, but more efficient and quicker pressure development at higher rpms.

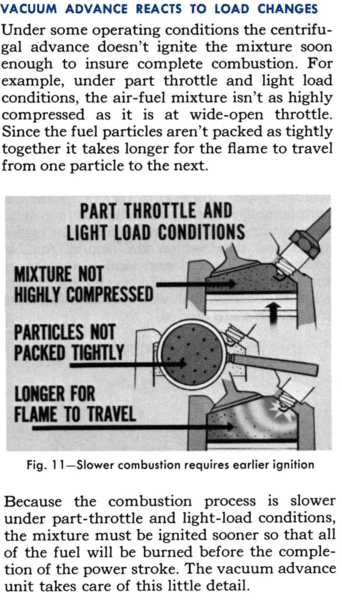

Vacuum Advance:

from Ignition System Analysis (Session 259) from the Master Technician's Service Conference

That's the crux of it isn't it.

Whether the piston is 28* or 25* into the power stroke probably depends on the crank arm and rod and stroke ratios. Need to think about that or run some examples. Thats one of those little details that makes each engine a little different. But it really doesn't matter, the concept is the same.

Reposting for those that may be not following why we're talking about pressure in the cylinder. It's all about maximizing leverage on the crank.

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because combustion efficiency increases with rpms. This means decreased burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opposite, poor - slow combustion at low rpms, but more efficient and quicker pressure development at higher rpms.

Vacuum Advance:

from Ignition System Analysis (Session 259) from the Master Technician's Service Conference