So much misinformation. I think there's someone who needs to completely relearn what ported vacuum advance is all about. What a train wreck. To the OP, good luck!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Large RPM and Vacuum drop when shifting from park to gear

- Thread starter Charlie_es_cool

- Start date

-

Mattax

Just the facts, ma'am

The chrysler distributors can have a many different advance curves. I don't know how close one for a '75 might be to '73, and the one you have might be a generic parts store replacement, or if lucky a Mopar Performance version.these graphs are awesome. And yes, I understand what you say about the distributor and how I'm already seeing mechanical advance at my idle speed.

I'll have another look at it tomorrow, but I think my distributor is an OEM style one. If this is the case, could I correct when my mechanical advance comes in with heavier springs? Or will I need a different ditributor?

Yes the springs can be changed. Changing the springs changes the advance rate (slope) and can also effect the rpm when the advance begins.

There is no good easy source to buy the correct spring. So changing springs requires some experimentation. However there are some other adjustments than require less experimentation.

There are several adjustments that can be made to the mechanical advance.

1. Adjustment of the rpm when the advance begins can be made by adjusting the tension on the light spring.

2. Adjustment of when the advance slows can be made in the same manner by adjusting the long looped spring's perch so it contacts sooner.

Those two adjustments can be made without taking off the reluctor, pickup, and advance plate once you've modified a screwdriver to fit the perches. Another picture here

3. Reducing the amount of advance by increasing or decreasing the allowable movement of the weights.

3a. Shortening the slot length on the outside stops the advance early.

3b. Shortening the slot length on the inside puts more tension on the primary spring and makes the first rapid part of the advance shorter.

If it turns out that your distributor has an advance that looks something like that '73, shortening the slot this way gets the advance curve pretty close to something a hot rodded engine would prefer. It does require disassembly and welding.

More pics here.

Below illustrates what this does using the same '73 timing example.

Set at 6* initial, that alone would provide a stronger idle for a close to stock 318.

For a hot rodded engine, more inital will help with the lack of compression and exhaust dilution due to overlap. How much more depends on the cam and compression.

For this example lets say 10 to 12* is the target.

The distributor disassembly is a little tricky. The most difficult step is removing the internal spring clip. There's some how-to and photos in linked thread we can provide more pointers if/when the time comes.

In the meantime, measure timing at various rpms to plot more of the advance curve. Be safe!

Last edited:

Charlie_es_cool

Well-Known Member

Hello Everyone.

I finally got to look into my mechanical advance. Here are my results:

19 @ initial

22 @ 2100

31 @ 2500

36 @ 2700 (all in at this point)

I advanced my timing 3 degrees since I was getting 33 degrees total with my previous tune up.

I finally got to look into my mechanical advance. Here are my results:

19 @ initial

22 @ 2100

31 @ 2500

36 @ 2700 (all in at this point)

I advanced my timing 3 degrees since I was getting 33 degrees total with my previous tune up.

Mattax

Just the facts, ma'am

That looks like a problem for car that ought to be using vac advance, BUT that may be jumping the gun.

Not enough info here. What's the timing below 2000 rpm? What's the slowest idle speed attained with the engine warmed up? What is the drop in rpm when placed in gear?

Charlie_es_cool

Well-Known Member

View attachment 1715612493

That looks like a problem for car that ought to be using vac advance, BUT that may be jumping the gun.

Not enough info here. What's the timing below 2000 rpm? What's the slowest idle speed attained with the engine warmed up? What is the drop in rpm when placed in gear?

Mechanical advance starts coming in at 1700. So up until 1700, it's still 19 degrees. Lowest idle speed is 1200 in park and drops to 900 in gear, which is an improvement from the 1000 rpm drop I was experiencing before I made any adjustments.

Additionaly, I have another problem elsewhere that might be the culprit behind all this. Yesterday I used the car and it stalls under light throttle. Made another thread on it. Wouldn't surprise me that whatever is causing that is also affecting my idle quality.

Mattax

Just the facts, ma'am

You have to start with the idle and off idle. Only time this can be somewhat ignored is a drag race only car. It still has to be somewhat right because the longer it takes for the engine to get what it needs at lower rpms, the longer it will take to get the combustion correct as it moves to higher rpms.Mechanical advance starts coming in at 1700. So up until 1700, it's still 19 degrees. Lowest idle speed is 1200 in park and drops to 900 in gear, which is an improvement from the 1000 rpm drop I was experiencing before I made any adjustments.

Additionaly, I have another problem elsewhere that might be the culprit behind all this. Yesterday I used the car and it stalls under light throttle. Made another thread on it. Wouldn't surprise me that whatever is causing that is also affecting my idle quality.

Here's the secret: You can't force feed an engine. The beauty of the carbureted system is it provides exactly what the engine wants as soon as it wants it. If it has an upset stomache (poor combustion) then the air velocity past the boosters is not going to be same as it will when its getting a good burn and drawing hard.

It doesn't make sense that it was advancing at 900 rpms two weeks ago and now it doesn't begin advancing until 1700 rpm.

You leaving something out of the story?

Ignition timing like you have now

very well may be the cause of no power under light throttle.

The timing should be advancing before 1000 rpm, preferably lower but its not reasonable to expect to get there in one shot. Its going to take several iterations. Get it down to 1000 or even 1200 for now.

Cam is unknown, but unless its extremely wild, 19* is a pretty high initial. 300 rpm drop is still pretty high as well.

It time to talk about the carb.

The idle speed screw opens the primary throttle plates.

Under the throttle plates the Holley idle circuit has two fuel outlets; the idle port and part of the 'transfer slot'.

We can restrict the fuel through the idle port with the idle mix screws.

Fuel through the exposed portion of the transfer slot depends on how much of it is under the throttle plates vs above the plates.

There is only a limited range of throttle positions which the transfer slots will work properly.

Properly means that if we steal too much or provide too little of the slots for idle, they won't be able to provide the correct amount of fuel for off-idle driving. Pretty much all light throttle driving is done on the so called idle system. (Above 60 mph or so, light throttle cruising is often on the 'main' circuit because the friction and wind loads are high enough to need just a bit more throttle.)

^^This^^ is why it is critical that the throttle position at idle results in no more than .040" of the transfer slot exposure to the manifold vacuum. On these newer Holley's even that is sometimes too much.

Set the throttles so the slots are around .025" visible. Count the number of 1/4 turns to open them to .035 and to closing down to .020. That's a reasonable working range for the idle speed screw.

With the engine warmed up, see if you can get the engine to idle within in this range. Trim the idle mix with the idle mix screws as needed after each adjustment.

On a radical engine it may need 19* initial, esp if lower compression. And 900 rpm may be as low as you can get, at least for now.

On a more moderately cammed engine, 12 to 15* at 700 to 800 rpm; and in between 15 to 18* at 700 to 850 is reasonable expectations.

Above idle rpm, the timing should advance rapidly until 16 to 1800 rpm, then advance more slowly. The more efficient the engine combustion gets, the less advance it will need.

Last edited:

Mattax

Just the facts, ma'am

Timing and fueling work together.

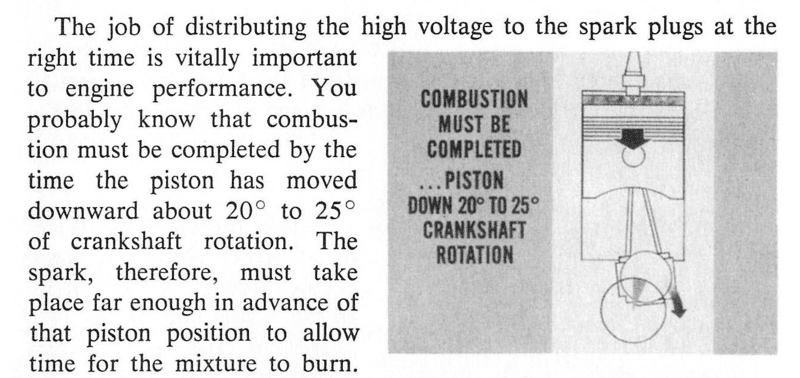

Pages 5,6,7 in this Chrysler booklet cover the concept. Ignition System Analysis (Session 259) from the Master Technician's Service Conference

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because combustion efficiency increases with rpms. This means decreased burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opposite, poor - slow combustion at low rpms, but more efficient and quicker pressure development at higher rpms.

Vacuum Advance:

Pages 5,6,7 in this Chrysler booklet cover the concept. Ignition System Analysis (Session 259) from the Master Technician's Service Conference

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because combustion efficiency increases with rpms. This means decreased burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opposite, poor - slow combustion at low rpms, but more efficient and quicker pressure development at higher rpms.

Vacuum Advance:

yellow rose

Overnight Sensation

Great Post once again from Mattax.

Yep. He always has the straight poop.

-

Similar threads

- Replies

- 53

- Views

- 2K

- Replies

- 83

- Views

- 4K